Assembly In Electronics

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

About assembly in electronics

Where to Find Electronics Assembly Suppliers?

China remains a dominant force in global electronics assembly manufacturing, with key production hubs concentrated in Guangdong and Tianjin offering distinct competitive advantages. Shenzhen, located in Guangdong, hosts a dense ecosystem of PCB and electronic components suppliers, enabling rapid prototyping and low-volume customization. The region benefits from proximity to semiconductor foundries and logistics gateways, reducing component lead times by 20–30% compared to non-specialized regions. Meanwhile, Tianjin’s industrial base focuses on machinery-integrated assembly solutions, supporting high-precision automation for large-scale production lines.

These clusters provide vertically integrated supply chains—from bare PCB fabrication to final box-build assembly—allowing streamlined coordination between design, sourcing, and production phases. Buyers gain access to facilities equipped with SMT lines, automated optical inspection (AOI), and in-circuit testing (ICT), ensuring consistent quality across batch sizes. Typical advantages include MOQs as low as 1–2 pieces for prototypes, scalable production capacity, and compliance with international standards such as RoHS and ISO. Lead times average 7–15 days for sample boards and 20–30 days for full production runs, depending on complexity and volume.

How to Choose Electronics Assembly Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria to ensure technical reliability and operational consistency:

Technical and Quality Compliance

Verify adherence to recognized standards including ISO 9001 for quality management, RoHS for hazardous substance restrictions, and UL certification where applicable. Suppliers should provide documentation for material traceability, solder paste inspection reports, BOM validation, and programming logs for ICs. For high-reliability applications, confirm capabilities in HDI, rigid-flex PCB assembly, and precision handling of small components (e.g., 01005 packages).

Production Capacity and Capabilities

Assess core infrastructure and process maturity:

- Support for multilayer PCBs (up to 16 layers or higher)

- In-house SMT and through-hole assembly lines

- Automated optical inspection (AOI) and X-ray inspection for BGA packages

- Customization options including component substitution, logo printing, and packaging design

Cross-reference on-time delivery performance (target ≥98%) and response time (ideally ≤2 hours) as indicators of operational efficiency.

Transaction and Risk Mitigation Practices

Prioritize suppliers with transparent transaction histories and reorder rates above 30%, indicating customer retention and service satisfaction. Utilize secure payment mechanisms and request sample assemblies before committing to volume orders. Confirm the ability to accept Gerber files, BOMs, and netlists, and evaluate engineering support responsiveness during pre-production queries.

What Are the Best Electronics Assembly Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization | Key Capabilities |

|---|---|---|---|---|---|---|---|

| Tecoo Electronics Co., Ltd. | PCBA, Multilayer PCB, Oven & Appliance Parts | 98% | 34% | ≤2h | US $460,000+ | Yes | Precision assembly, FR4 materials, reverse engineering, BOM management, automated inspection, IC programming |

| Guangzhou Guangming Electromechanical Equipment Engineering Co., Ltd. | Air Conditioner Parts, Inverter PCBAs | 98% | 18% | ≤2h | US $90,000+ | Limited | OEM replacements, board cloning, appliance-specific assembly |

| Toptek Pcb Co., Limited | HDI, Rigid-Flex, Multilayer Boards | 100% | 66% | ≤2h | US $1,000+ | Yes | High-frequency PCBs, RoHS-compliant lead-free assembly, ISO-certified processes |

| Shenzhen Seeme Technology Co., Ltd. | PCBA, Smart GPS Trackers, Consumer Electronics | 100% | 33% | ≤5h | US $10,000+ | Yes | Custom PCBA services, multi-layer boards, BOM fulfillment, Gerber-based production |

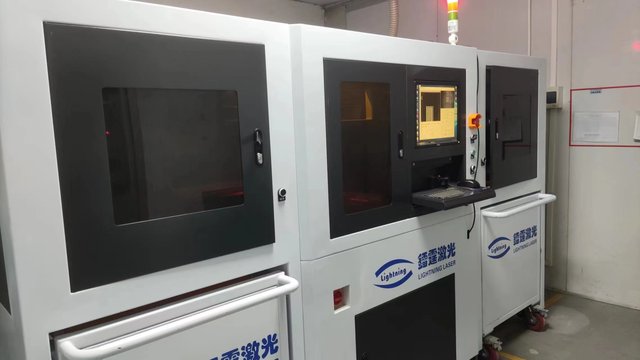

| Tianjin Huachuanyuan Electronic Sales Co., Ltd. | Electronics Production Machinery | 100% | - | ≤2h | US $2,000+ | No | SMT line equipment, automatic cutting and assembly machines, LED production systems |

Performance Analysis

Tecoo Electronics stands out for its broad product range and high online revenue, indicating strong market presence and diversified output in both consumer and industrial PCBA sectors. Toptek Pcb and Shenzhen Seeme demonstrate perfect on-time delivery records and robust customization capabilities, making them ideal for low-to-mid volume OEM projects requiring fast turnaround. Notably, Toptek achieves a 66% reorder rate—the highest among listed suppliers—suggesting exceptional customer satisfaction in niche high-frequency and rigid-flex applications. Guangzhou Guangming specializes in replacement assemblies for HVAC systems, catering to maintenance and repair markets with minimal customization. Tianjin Huachuanyuan differs as a capital equipment supplier, providing full SMT production lines rather than assembly services, relevant for buyers establishing in-house manufacturing.

FAQs

How to verify electronics assembly supplier reliability?

Validate certifications (ISO, RoHS, UL) through official databases or third-party audit reports. Request evidence of quality control procedures, including AOI logs, solder paste inspection results, and functional testing protocols. Evaluate supplier responsiveness and technical clarity during initial inquiries as proxies for long-term collaboration efficiency.

What is the typical minimum order quantity (MOQ)?

MOQs vary by supplier and complexity. Prototype orders often start at 1–2 units, while automated SMT production may require 50+ units for cost efficiency. Some suppliers offer no-MOQ services for simple designs at higher per-unit pricing.

What are common lead times for PCB assembly?

Standard lead time ranges from 7–15 days for samples and 20–30 days for mass production. Expedited services (3–5 days) are available from select suppliers for prototype builds, subject to component availability and design complexity.

Can suppliers handle component sourcing and substitutions?

Yes, most full-turnkey providers manage BOM procurement, including approved vendor lists and authorized substitutions. Confirm policies on part alternatives, counterfeit prevention, and traceability documentation prior to order placement.

Do electronics assembly suppliers support global shipping?

All listed suppliers export internationally. Confirm Incoterm preferences (FOB, CIF), customs documentation support, and packaging standards for sensitive electronic goods. Air freight is standard for samples; sea freight is economical for container-sized shipments.