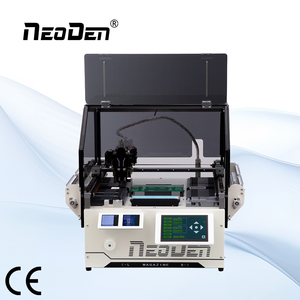

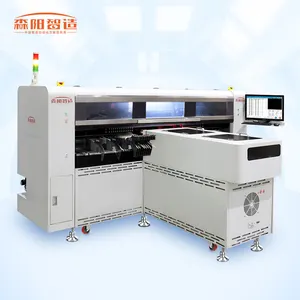

Electronics Assembly Machine

CN

CN

CN

CN

About electronics assembly machine

Where to Find Electronics Assembly Machine Suppliers?

China remains the global epicenter for electronics assembly machine manufacturing, with key supplier clusters concentrated in Zhejiang, Guangdong, and Jiangsu provinces. Wenzhou and Hangzhou in Zhejiang province host specialized manufacturers of precision SMT (Surface Mount Technology) equipment, leveraging regional expertise in automation engineering and integrated circuit handling. Shenzhen, a core city in Guangdong’s Pearl River Delta, offers dense ecosystems of component suppliers, contract manufacturers, and R&D centers, enabling rapid prototyping and agile production scaling.

These industrial hubs benefit from vertically integrated supply chains—spanning servo motors, vision systems, feeder mechanisms, and control software—reducing lead times by 25–40% compared to offshore alternatives. Facilities within these zones typically operate under ISO 9001-aligned quality management frameworks and maintain proximity to Tier-1 EMS providers, ensuring compatibility with global electronics production standards. Buyers can expect standard delivery windows of 30–60 days for desktop or mid-range automated systems, with localized technical support and modular customization readily available.

How to Choose Electronics Assembly Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Standards

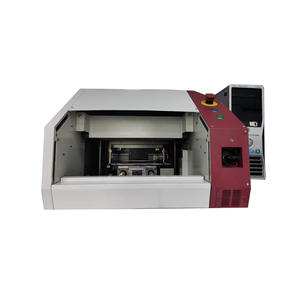

Verify adherence to international safety and environmental regulations, including CE marking for EU market access and RoHS compliance for hazardous substance restrictions. For high-mix PCB assembly applications, confirm machine compatibility with JEDEC-standard component packaging (tape & reel, trays, sticks) and support for nozzles across multiple sizes (e.g., 0201 to 2512). Request documentation on positioning accuracy (typically ±0.025mm–±0.05mm), placement speed (CPH rates), and vision system resolution (optical magnification ≥10x).

Production Capability Assessment

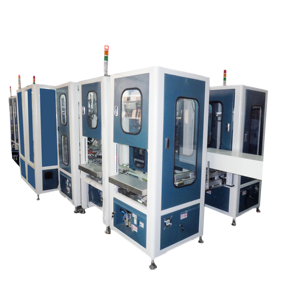

Evaluate supplier infrastructure using the following benchmarks:

- Minimum factory area exceeding 2,000m² for dedicated SMT/automation lines

- In-house engineering teams capable of customizing feeder configurations, conveyor widths, and software interfaces

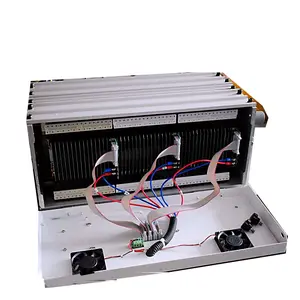

- Integration capabilities with upstream (solder paste inspection) and downstream (reflow soldering) processes

Cross-reference online revenue indicators and reorder rates as proxies for market validation. Prioritize suppliers with proven export experience and multilingual technical support.

Procurement Safeguards

Utilize secure payment mechanisms such as trade assurance or escrow services until post-delivery performance verification is complete. Conduct remote audits via live video tours to validate CNC machining centers, calibration labs, and final assembly bays. Require sample testing under real-world conditions—measuring placement yield over 1,000 cycles—and insist on firmware version transparency to avoid obsolescence risks.

What Are the Best Electronics Assembly Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Min. Order Value |

|---|---|---|---|---|---|---|---|---|

| Wenzhou Zhengbang Electronic Equipment Co., Ltd. | Zhejiang, CN | Pick-and-place machines, SMT systems | US $140,000+ | 94% | ≤2h | <15% | Fully customizable nozzles, feeders, PCB holders, packaging | $23–$12,000/set |

| Shenzhen Xiaomao Automation Technology Ltd. | Guangdong, CN | Desktop CNC, screw-robot systems | US $30,000+ | 61% | ≤2h | 43% | Adjustable jigs, material types, screw size, labeling | $400–$3,040/set |

| Hangzhou Shenpei Technology Co., Ltd. | Zhejiang, CN | Electronic jacquard cylinders | US $10,000+ | 100% | ≤7h | 50% | Limited to textile machinery components | $1,565–$1,769/piece |

| Dongguan Yicheng Automation Equipment Co., Ltd. | Guangdong, CN | PLC-controlled assembly lines | Not disclosed | 100% | ≤6h | No data | Full line customization, motor coolers, armature systems | $20,000–$120,000/set |

| Shenzhen Wenzhan Electronic Technology Co., Ltd. | Guangdong, CN | SMT pick-and-place, full-line solutions | US $560,000+ | 97% | ≤2h | <15% | PCB handling, nozzle sets, label graphics, cleaning modules | $3,200–$62,000/piece/set |

Performance Analysis

Shenzhen Wenzhan leads in scale and reliability, with the highest online revenue (US $560,000+) and a 97% on-time delivery rate, indicating robust production planning. Wenzhou Zhengbang offers strong value for entry-level SMT setups, providing full customization at competitive pricing starting below $3,000. Despite lower reorder rates, both demonstrate responsiveness (≤2h), critical for issue resolution during commissioning. Dongguan Yicheng specializes in large-scale turnkey lines, targeting high-capital buyers requiring fully integrated systems. In contrast, Shenzhen Xiaomao shows moderate delivery performance (61%) despite high customer retention (43%), suggesting potential bottlenecks in fulfillment capacity. Hangzhou Shenpei, while achieving perfect on-time delivery, operates primarily in non-core niches (textile electronics), limiting relevance for mainstream PCB assembly needs.

FAQs

How to verify electronics assembly machine supplier reliability?

Cross-check ISO and CE certifications through official databases. Request evidence of machine testing protocols, including vacuum nozzle consistency, X/Y/Z axis repeatability logs, and thermal stability reports. Analyze buyer feedback focusing on after-sales service response and spare parts availability.

What is the typical MOQ and lead time?

Most suppliers accept single-unit orders (MOQ: 1 set), especially for desktop or semi-automatic models. Lead times range from 15 days for in-stock units to 45–60 days for customized configurations. Turnkey SMT lines may require 75–90 days depending on complexity.

Can suppliers customize electronics assembly machines?

Yes, leading suppliers offer extensive customization: adjustable conveyor widths (8–400mm), selectable head counts (4–12 heads), multi-feeder support (8–80+ slots), and software integration (Windows/Linux-based GUIs). Custom branding, language localization, and I/O interface modifications are commonly available.

Do suppliers provide technical training and support?

Reputable manufacturers include basic setup guidance and instructional videos. Advanced support—such as remote diagnostics, firmware updates, and on-site technician deployment—is often offered under extended service agreements. Confirm inclusion of English manuals, error code documentation, and maintenance schedules prior to purchase.

Are used or refurbished machines available?

Some suppliers list reconditioned units with partial warranties. Buyers should request detailed refurbishment records, including replaced components (motors, sensors, drives), calibration certificates, and operational hour logs to assess residual lifespan accurately.