Assembly Line Description

About assembly line description

Where to Find Assembly Line Suppliers?

China remains the global hub for industrial assembly line manufacturing, with key supplier clusters concentrated in Shanghai, Zhejiang, Guangdong, and Henan provinces. These regions host vertically integrated production ecosystems that support rapid prototyping, scalable fabrication, and cost-efficient component sourcing. Shanghai and Zhejiang specialize in electronics and ESD-safe assembly systems, leveraging proximity to semiconductor and consumer electronics industries. Guangdong’s Shenzhen-based suppliers focus on modular conveyor solutions and automation integration, while Henan has emerged as a center for heavy-duty automotive and machinery production lines.

The geographic clustering enables streamlined supply chains—raw materials, control systems, and structural components are sourced within 50–100 km, reducing lead times by up to 30%. Facilities typically operate under ISO-compliant quality management frameworks, with average lead times ranging from 20–45 days depending on customization level. Buyers benefit from flexible MOQs (as low as 1 set or 1 meter for linear systems), competitive pricing due to localized steel and motor sourcing, and strong engineering support for bespoke configurations.

How to Choose Assembly Line Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify CE certification for electrical safety and mechanical conformity, particularly for export to EU and North American markets. For electronics and cleanroom applications, confirm ESD protection standards (e.g., ANSI/ESD S20.20). Request documentation for core components such as motors, belts, and control panels. Suppliers offering CE-certified lines demonstrate adherence to standardized design and testing protocols.

Production Capability Assessment

Evaluate the following indicators of manufacturing maturity:

- Minimum factory area exceeding 3,000m² for dedicated production zones

- In-house engineering teams capable of custom layout design and PLC integration

- On-site welding, CNC cutting, and surface treatment capabilities

Cross-reference product listings with response time and on-time delivery metrics—suppliers maintaining ≤8-hour response times and 100% on-time performance typically have robust order management systems.

Customization and Quality Control

Confirm the supplier’s ability to provide CAD layouts, 3D renderings, or video walkthroughs of proposed assembly lines. Prioritize vendors offering pre-shipment inspection options and test runs. Review their QC process: leading manufacturers conduct load tests, speed calibration, and electrical safety checks before dispatch. For automated or robotic-integrated lines, demand validation of programming logic and fail-safe mechanisms.

What Are the Best Assembly Line Suppliers?

| Company Name | Location | Main Products | Assembly Line Listings | On-Time Delivery | Avg. Response | Min. Order | Price Range (USD) | Revenue Tier |

|---|---|---|---|---|---|---|---|---|

| Shanghai Detall Electronics Technology Ltd | Shanghai, CN | Workbenches, ESD Lines, Conveyors | 54 | - | ≤9h | 1 set | $296–$1,400 | US $10,000+ |

| Zhejiang Anmax Intelligent Equipment Co., Ltd. | Zhejiang, CN | Furniture, Motorcycle, LED Lines | 9 | 100% | ≤16h | 1 set | $3,000–$20,000 | Not specified |

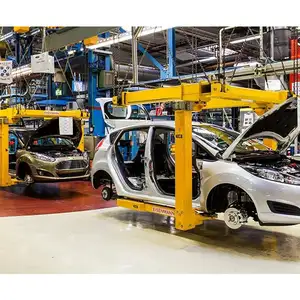

| Dongguan Yicheng Automation Equipment Co., Ltd. | Guangdong, CN | Automotive, Motor, Switch Lines | 27 | 100% | ≤7h | 1 set | $18,000–$120,000 | Not specified |

| Shenzhen Shunqiang Technology Co., Ltd. | Guangdong, CN | Conveyors, Chain Lines | 40 | 100% | ≤1h | 1 meter | $190–$500/m | US $60,000+ |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Henan, CN | Automotive, EV, Truck Lines | 547 | 100% | ≤8h | 1 set | $5,800–$256,000 | Not specified |

Performance Analysis

Zhengzhou Duoyuan leads in scale and specialization, with over 500 listed assembly line configurations focused on automotive manufacturing, including electric vehicle and truck production systems. Their high price range reflects full-line turnkey capabilities. Shenzhen Shunqiang stands out for responsiveness (≤1h) and granular purchasing options (per-meter pricing), ideal for incremental expansion or repair. Dongguan Yicheng serves high-precision sectors like motor and switch assembly, with orders starting above $18,000, indicating advanced automation integration. Zhejiang Anmax targets furniture and lighting industries with mid-range systems, while Shanghai Detall offers entry-level ESD and mobile phone assembly workstations at sub-$300 price points. All top-tier suppliers maintain 100% on-time delivery records where reported, signaling strong production planning discipline.

FAQs

How to verify assembly line supplier reliability?

Cross-check certifications (CE, ISO) through official databases. Request factory audit reports or video tours to assess infrastructure. Analyze historical transaction data, focusing on consistent on-time delivery and buyer feedback related to post-installation support and system durability.

What is the typical lead time for custom assembly lines?

Standard configurations ship within 20–30 days. Custom designs with PLC controls or automation integration require 35–60 days, depending on complexity. Prototype validation adds 7–14 days if required.

Can suppliers handle global shipping and installation?

Yes, experienced exporters offer FOB or CIF terms with containerized packing. Some provide optional on-site installation guidance or remote commissioning support. Confirm whether electrical specifications (voltage, frequency) are compatible with destination country standards.

Do suppliers accept small orders or samples?

Most accept single-set orders or per-meter purchases for conveyors. Sample units are available for functional testing; fees may apply but are often credited toward bulk orders. Minimum order flexibility is common across all five profiled suppliers.

How to initiate a customized assembly line request?

Provide detailed requirements: product dimensions, cycle time, workstation count, power supply, conveyor type (belt, chain, overhead), and environmental conditions (e.g., ESD protection). Reputable suppliers respond with layout proposals and component specifications within 48–72 hours.