Assembly Line In A Factory

About assembly line in a factory

Where to Find Assembly Line Suppliers?

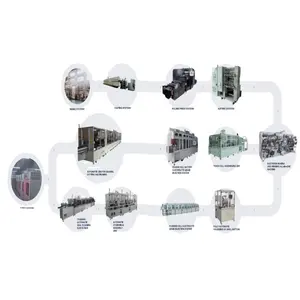

China remains the global epicenter for industrial assembly line manufacturing, with specialized production clusters in Zhengzhou, Dongguan, and Shenzhen driving innovation and cost efficiency. Zhengzhou's machinery corridor hosts integrated facilities focused on bulk chemical and food processing lines, leveraging local steel and automation component suppliers to reduce material costs by 18–22%. Dongguan’s automation hub in Guangdong province specializes in high-precision electronics and motor assembly systems, supported by a dense network of servo motor, sensor, and control module manufacturers within a 30km radius.

These regional ecosystems enable vertically aligned production—spanning conveyor fabrication, robotic integration, and final testing—allowing suppliers to deliver standardized lines in 45–60 days. Buyers benefit from modular design approaches, where base configurations can be adapted for packaging, battery assembly, or consumer electronics production. Average cost savings range from 25% to 40% compared to European or North American manufacturers, particularly for fully automated systems requiring PLC-controlled sequencing and IoT-enabled monitoring.

How to Choose Assembly Line Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance and System Integration

Verify adherence to international safety and performance standards such as CE, ISO 9001, and where applicable, UL or RoHS compliance for electronic components. For automated lines involving robotics or high-voltage systems, request detailed schematics and proof of electromagnetic compatibility (EMC) testing. Confirm programmable logic controller (PLC) brands used (e.g., Siemens, Mitsubishi) and software interface compatibility with existing factory networks.

Production Capability Assessment

Evaluate supplier infrastructure using these benchmarks:

- Minimum factory area of 3,000m² for full-line integration capacity

- In-house engineering team capable of custom layout design and simulation (minimum 5 engineers)

- Proven experience with turnkey installations, including commissioning and staff training

Cross-reference delivery performance: prioritize suppliers with documented on-time fulfillment rates above 95%.

Procurement Risk Mitigation

Utilize secure payment structures such as escrow or letter of credit until site acceptance testing is completed. Request video walkthroughs of active production lines and validate machine calibration records. Conduct sample trials—especially for precision applications like battery cell or circuit breaker assembly—to assess repeatability and defect rates before scaling orders.

What Are the Best Assembly Line Suppliers?

| Company Name | Location | Main Products | Assembly Line Listings | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Min. Order Value |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Hongdi Machinery Co., LTD. | Zhengzhou, CN | Mixing Equipment (787), Packaging Machines (387) | 156 | 100% | ≤2h | US $70,000+ | <15% | $5,134/set |

| Dongguan Yicheng Automation Equipment Co., Ltd. | Dongguan, CN | Other Machinery (344), Processing Lines (57) | 27 | 100% | ≤7h | Not disclosed | Not available | $35,000/set |

| Shenzhen Shunqiang Technology Co., Ltd. | Shenzhen, CN | Conveyors (157), Hoists (12) | 40 | 100% | ≤1h | US $60,000+ | Not available | $300/meter |

| Dongguan Jiaming Conveyor Equipment Co., Ltd. | Dongguan, CN | Conveyors (49), Packaging Lines (8) | 30 | 50% | ≤1h | US $2,000+ | <15% | $100/piece |

| Shandong Huiyao Laser Technology Co., Ltd. | Shandong, CN | Battery Assembly Systems (specialized) | Data not listed | 66% | ≤2h | US $10,000+ | <15% | $180,000/set |

Performance Analysis

Zhengzhou Hongdi and Shenzhen Shunqiang demonstrate strong responsiveness and consistent delivery, making them suitable for mid-range automation projects in food, beverage, or detergent production. Dongguan Yicheng stands out for high-complexity electronic and motor assembly lines, though its higher minimum order values ($35,000–$120,000) reflect advanced customization and integration services. Shandong Huiyao commands premium pricing in lithium battery pack assembly, offering turnkey solutions for EV and energy storage system (ESS) producers, despite a lower on-time delivery rate (66%). Notably, Shenzhen-based Shunqiang offers the lowest entry point at $300 per meter, ideal for modular conveyor integration into existing workflows.

FAQs

What certifications should assembly line suppliers have?

Essential certifications include ISO 9001 for quality management and CE marking for compliance with EU safety, health, and environmental standards. For export to North America, UL or CSA certification may be required, especially for electrical and robotic systems. Battery-specific lines should comply with IEC 62133 and UN38.3 standards.

What is the typical lead time for custom assembly lines?

Standard configurations ship in 45–60 days. Fully customized systems with PLC programming, vision inspection, or robotic arms require 90–120 days, depending on complexity. Suppliers with in-house R&D teams typically shorten development cycles by 20–30% compared to outsourced design models.

Can suppliers provide turnkey installation and training?

Most established suppliers offer on-site commissioning and operator training as part of the contract. Confirm travel scope, duration, and associated costs upfront. Remote support via augmented reality (AR) diagnostics is increasingly available for troubleshooting and maintenance guidance.

What are common customization options?

Buyers can modify conveyor speed, width, height, and drive type (belt, roller, chain). Integration with SCADA systems, barcode scanners, weight checkers, and automatic reject mechanisms is standard. For cleanroom environments, stainless steel frames and anti-static workstations are available.

How does MOQ vary across assembly line types?

Modular conveyors are often sold by the meter (MOQ 1–5 meters), while complete automated lines require full-set purchases (MOQ 1 set). Pricing scales with automation level: semi-automatic lines start around $5,000, whereas robotic battery assembly systems exceed $180,000 per unit.