Assembly Line Machines

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

About assembly line machines

Where to Find Assembly Line Machines Suppliers?

China remains the global epicenter for assembly line machine manufacturing, with key production clusters in Guangdong, Jiangsu, and Guangzhou enabling high-efficiency automation solutions across industries. These regions host vertically integrated supply chains—spanning conveyor systems, robotic integration, and programmable logic control (PLC) engineering—that support rapid prototyping and scalable deployment. Guangdong alone accounts for over 40% of China’s industrial automation exports, driven by Shenzhen’s electronics ecosystem and Foshan’s advanced machinery parks.

The concentration of component suppliers, R&D centers, and export logistics hubs within these zones reduces lead times by 25–35% compared to decentralized markets. Buyers benefit from localized access to CNC machining, stainless steel fabrication, and polymer belt production, allowing for seamless customization of speed, load capacity, and integration with existing factory control systems. Average delivery windows range from 30–60 days depending on complexity, with standard configurations available in as little as four weeks.

How to Choose Assembly Line Machines Suppliers?

Selecting reliable partners requires a structured evaluation of technical, operational, and transactional capabilities:

Technical Compliance & Certifications

Verify adherence to international quality standards such as ISO 9001 for quality management and CE marking for electrical safety compliance. For medical or food-grade applications, confirm FDA or EU hygiene directives are met. Request documentation for motor efficiency ratings (IE2/IE3), PLC compatibility (Siemens, Allen-Bradley), and material certifications (e.g., food-safe PU/PVC belts).

Production Capacity Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum facility size of 3,000m² to ensure dedicated assembly and testing zones

- In-house engineering teams capable of customizing conveyor width, incline angle, drive systems, and automation interfaces

- Proven experience integrating vision inspection, RFID tracking, or robotic arms into production lines

Cross-reference online revenue indicators and on-time delivery rates (target ≥95%) to assess order fulfillment reliability.

Customization and Transaction Security

Confirm suppliers offer configurable options including belt type (PVC, stainless steel chain plate), frame materials (aluminum, carbon steel), and modular extensions. Prioritize vendors providing 3D design previews and pre-shipment testing reports. Utilize secure payment mechanisms tied to milestone verification, especially for high-value orders exceeding $50,000.

What Are the Best Assembly Line Machines Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Sample MOQ | Avg. Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

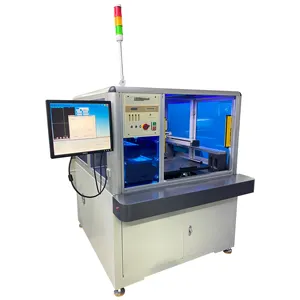

| Guangdong SONGKE LEADING INTELLIGENT EQUIPMENT CO., LIMITED | Assembly Line, Battery Testers, Spot Welders | 100% | ≤2h | 100% | $10,000+ | Full automation, laser welding, battery cycle integration | 1 set | $1,880 – $450,000 |

| Tiantech Group Co., Ltd. | Washing Machine, Refrigeration Assembly Lines | 100% | ≤7h | <15% | $290,000+ | OEM/ODM for home appliance production lines | 1 piece | $50,000 – $150,000 |

| Guangdong Weitaopu Automation Equipment Co., Ltd. | Energy Storage, Lithium Battery Assembly Lines | 100% | ≤3h | - | - | Laser welding, lead-to-lithium conversion systems | 1 piece | $186 – $7,999 |

| Changzhou Hejin Yue International Trade Co., Ltd. | PVC Belt Conveyors, Chain Plate Systems | 100% | ≤7h | - | - | Color, size, logo, packaging customization | 1 m² | $56 – $399 |

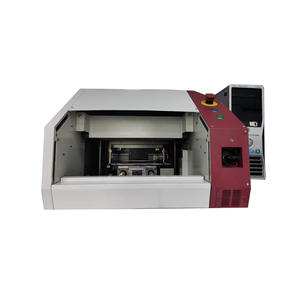

| Guangzhou Minder-Hightech Co., Ltd. | Electronics Production Machinery, Welding Equipment | 50% | ≤5h | 80% | $280,000+ | Chip bonding, labeling, graphic design integration | N/A | N/A |

Performance Analysis

Guangdong-based SONGKE leads in responsiveness and customer retention, achieving a 100% reorder rate and sub-2-hour response time—indicative of robust after-sales support and system reliability. Tiantech Group targets large-scale appliance manufacturers with fully integrated washing machine and refrigerator assembly solutions priced at $50,000+, backed by substantial online revenue and verified production capacity. Mid-tier suppliers like Weitaopu and Hejin Yue specialize in modular conveyors and energy storage lines, offering lower entry costs and faster turnaround for niche automation needs. Notably, Guangzhou Minder-Hightech shows an unusually low on-time delivery rate (50%) despite high reorder activity, suggesting potential logistical bottlenecks despite strong product demand.

FAQs

How to verify assembly line machine supplier reliability?

Request certified quality management system documentation (ISO 9001), proof of export compliance (CE, RoHS), and third-party inspection reports. Conduct virtual factory audits to observe CNC machining, motor calibration, and final assembly processes. Analyze historical transaction data focusing on dispute resolution and post-delivery technical support.

What is the typical minimum order quantity (MOQ)?

MOQ varies by application: conveyor belts may require only 1 m², while full automated lines typically start at 1 set. High-complexity systems such as lithium battery or medical device assembly lines often have non-negotiable single-unit MOQs due to customization intensity.

Do suppliers support OEM/ODM projects?

Yes, most leading suppliers offer comprehensive OEM/ODM services, including branded control panels, proprietary software integration, and tailored mechanical configurations. Development timelines average 4–6 weeks from concept approval to prototype delivery.

What are common customization options?

Available modifications include belt material (PVC, PU, metal), frame finish (powder-coated, stainless steel), motor voltage (110V/220V/380V), speed control (VFD integration), and add-ons like barcode scanners, sensors, or robotic pick-and-place units. Custom branding via logos, labels, and color schemes is widely supported.

How long does it take to receive a sample or prototype?

Standard conveyor segments ship within 7–14 days. Fully automated assembly line prototypes require 25–45 days for design validation, component sourcing, and functional testing. Air freight adds 5–10 days for international delivery.