Assembly Of Printed Circuit Boards

Top sponsor listing

Top sponsor listing

1/61

1/61

1/31

1/31

CN

CN

1/20

1/20

1/37

1/37

1/34

1/34

1/26

1/26

1/44

1/44

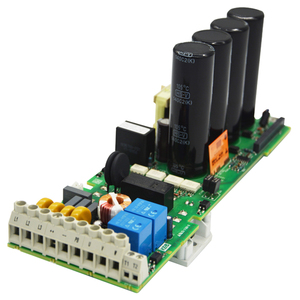

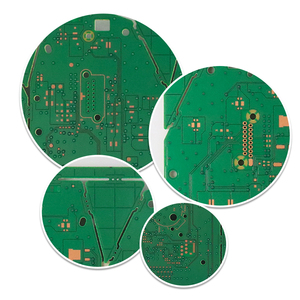

About assembly of printed circuit boards

Where to Find Assembly of Printed Circuit Boards Suppliers?

China remains the global epicenter for printed circuit board assembly (PCBA) manufacturing, with key industrial clusters concentrated in Shenzhen, Dongguan, and Dalian. These regions host vertically integrated supply chains that streamline prototyping, component sourcing, and high-volume production. Shenzhen alone accounts for over 40% of China’s electronics contract manufacturing output, supported by proximity to semiconductor suppliers and automated fabrication facilities.

The regional ecosystems enable rapid turnaround times—typically 5–10 days for prototype assemblies and 15–25 days for批量 orders—due to co-located SMT lines, testing labs, and logistics networks. Buyers benefit from cost efficiencies driven by localized material procurement and energy-optimized production zones, achieving 20–35% lower unit costs compared to North American or European alternatives. Specialization varies: Shenzhen excels in multilayer, rigid-flex, and high-frequency PCBs for telecom and IoT applications, while Dongguan focuses on aluminum-based thermal management substrates for power electronics.

How to Choose Assembly of Printed Circuit Boards Suppliers?

Selecting a reliable PCBA supplier requires structured evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to IPC-A-610 Class 2 or Class 3 standards for electronic assemblies. ISO 9001 certification is essential for process control; for medical or automotive applications, validate IATF 16949 or ISO 13485 compliance. Ensure RoHS and REACH declarations are available for material traceability. Request first-article inspection reports and in-circuit test (ICT) or AOI result samples before scaling production.

Production Capability Assessment

Evaluate core competencies through measurable benchmarks:

- Surface Mount Technology (SMT) line capacity: minimum 4 placement machines with ≤50μm accuracy

- Layer count support: up to 32-layer HDI for advanced designs

- Substrate expertise: FR4, aluminum, ceramic, and flexible polyimide (FPC)

- In-house capabilities including conformal coating, potting, and box-build assembly

Cross-reference online revenue indicators and order fulfillment rates to assess scalability and financial stability.

Procurement Risk Mitigation

Utilize secure payment structures such as milestone-based disbursements tied to production phases. Prioritize suppliers with documented reorder rates above 30%, indicating customer retention and service consistency. Conduct virtual audits via facility videos and real-time Q&A sessions to verify equipment conditions and workforce training protocols. Prototype sampling should include functional testing under simulated operating environments prior to full deployment.

What Are the Best Assembly of Printed Circuit Boards Suppliers?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Verified Type |

|---|---|---|---|---|---|---|---|---|

| Dongguan Tuopst Technology Co., Ltd. | Dongguan, CN | PCBA, Aluminum PCB, Multilayer PCB, FPC | - | 100% | ≤2h | 100% | US $3,000+ | - |

| Shenzhen Tobaina Technology Co., Ltd. | Shenzhen, CN | PCBA, Rigid-Flex PCB, GNSS & GPS Antennas, Communication Modules | - | 100% | ≤1h | <15% | US $50,000+ | - |

| Dalian Jy Electronics & Technology Co., Ltd. | Dalian, CN | PCBA, Custom Prototypes, Multilayer PCB | Color, Material, Size, Logo, Packaging, Label, Graphic | 100% | ≤1h | 44% | US $300,000+ | Custom Manufacturer |

| Shenzhen Kingsheng Tech. Co., Ltd. | Shenzhen, CN | PCBA, Multilayer PCB, FPC, Microcontrollers, FPGA | - | 66% | ≤4h | <15% | US $100,000+ | - |

| Shenzhen Yongchangtai Electronics Co., Ltd. | Shenzhen, CN | OEM/ODM PCBA, Medical & Industrial Control Boards | Color, Material, Size, Logo, Packaging, Label, Graphic | 100% | ≤2h | <15% | US $1,000+ | Multispecialty Supplier |

Performance Analysis

Dongguan Tuopst stands out with a perfect 100% reorder rate, suggesting exceptional client satisfaction and consistent delivery performance despite modest reported revenue. Shenzhen Tobaina and Dalian Jy offer sub-one-hour response times and broad product portfolios, with Dalian Jy demonstrating stronger customer retention (44% reorder rate), likely due to extensive customization capabilities. While Shenzhen Kingsheng reports higher revenue, its 66% on-time delivery rate presents a notable risk for time-sensitive projects. Suppliers with ISO 9001 certification—such as Shenzhen Yongchangtai—provide documented quality systems critical for regulated industries. For low-volume prototyping, prioritize suppliers offering MOQs of 1 piece and pricing below $0.50/unit; for volume runs, evaluate per-unit cost at 100+ quantities and confirm automated optical inspection (AOI) integration.

FAQs

How to verify assembly of printed circuit boards supplier reliability?

Validate certifications through issuing body databases. Request sample production records, including solder paste inspection (SPI) data and reflow profiles. Analyze transaction history metrics such as on-time delivery rate (>95% recommended) and response time consistency. Conduct video audits to observe SMT line operations and inventory management practices.

What is the typical lead time for PCBA prototypes?

Standard turnkey prototypes take 7–12 days from design submission to shipment. Expedited services can reduce this to 3–5 days using parallel processing and pre-stocked components. Complex builds involving blind vias, impedance control, or mixed technology may extend timelines by 3–7 additional days.

Do suppliers support small batch and custom orders?

Yes, most suppliers listed accommodate MOQs as low as one unit, particularly for prototype development. Customization options include silkscreen color, substrate thickness, finish type (HASL, ENIG, Immersion Silver), and packaging configuration. Design for Manufacturability (DFM) feedback is typically provided within 24 hours of Gerber file submission.

Are components sourced independently or provided by buyers?

Suppliers generally offer both turnkey and consigned models. In turnkey mode, they procure components from franchised distributors with traceable lot numbers. Buyers may provide specific ICs or connectors under consigned arrangements. Clarify ownership terms and excess material handling policies upfront.

Can PCBA suppliers handle end-to-end manufacturing?

Top-tier providers support full lifecycle services—from bare PCB fabrication and component sourcing to assembly, programming, functional testing, and final packaging. Integrated facilities reduce handoff delays and improve yield tracking. Confirm availability of X-ray inspection for BGA packages and environmental stress screening if required.