Atc Cnc Router Wholesale Customized

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/5

1/5

1/3

1/3

1/5

1/5

1/3

1/3

1/3

1/3

1/16

1/16

1/10

1/10

1/19

1/19

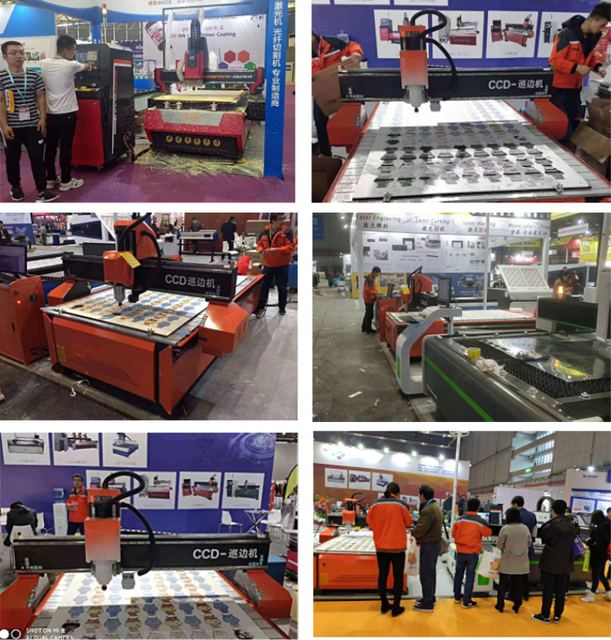

About atc cnc router wholesale customized

Where to Find ATC CNC Router Wholesale Customized Suppliers?

China remains the global epicenter for ATC CNC router manufacturing, with Shandong province emerging as a dominant hub for high-precision woodworking machinery. The region hosts vertically integrated production clusters specializing in automated tool change (ATC) systems, offering scalable solutions for wholesale procurement and OEM customization. These industrial ecosystems benefit from localized supply chains encompassing cast iron bed fabrication, servo motor integration, and linear guide rail assembly—reducing component lead times by up to 30% compared to decentralized manufacturing models.

Suppliers in Jinan and Foshan have developed specialized expertise in nesting routers, panel processing, and multi-axis wood carving machines, catering to cabinetry, furniture, and architectural millwork industries. Integrated R&D and production facilities enable rapid prototyping and batch manufacturing, with standard order fulfillment typically within 25–40 days. Buyers gain access to cost efficiencies driven by economies of scale, with production cost advantages of 20–35% over European and North American manufacturers, particularly for customized configurations requiring unique worktable sizes, spindle power ratings, or vacuum hold-down systems.

How to Choose ATC CNC Router Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Prioritize suppliers demonstrating in-house engineering capacity for custom design modifications. Key indicators include availability of CAD/CAM compatibility, multi-spindle configurations, 5-axis machining options, and swing head technology. Verify integration of critical subsystems such as automatic tool changers (8–16 tool stations typical), dust aspiration systems, and PLC control panels. Confirm use of hardened linear rails (e.g., HIWIN or PMI) and precision ball screws for long-term accuracy retention.

Quality Assurance Protocols

While formal ISO 9001 certification is not universally listed, consistent on-time delivery performance (≥97%) and documented response times serve as proxy indicators of process discipline. Suppliers with verified online transaction histories exceeding US $200,000 demonstrate sustained market presence and post-sales reliability. CE compliance should be confirmed for export markets in Europe, ensuring adherence to electromagnetic compatibility and machinery safety directives.

Customization & Transaction Safeguards

Assess customization scope beyond basic size adjustments—leading suppliers offer configurable options including:

- Working area dimensions (e.g., 1325, 1530, 2030, 2040 formats)

- Spindle power (3kW to 9kW air/water-cooled variants)

- Vacuum zoning and T-slot table combinations

- Integrated labeling, rotary axes, or auto-loading conveyors

Cross-reference product listings with response time metrics (target ≤4 hours) and reorder rates as proxies for customer satisfaction. Utilize secure payment mechanisms and request pre-shipment inspection reports to mitigate risk. Sample testing is recommended to evaluate cutting accuracy, noise levels, and software stability under continuous operation.

What Are the Best ATC CNC Router Wholesale Customized Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|

| Jinan JCUT CNC Equipment Co., Ltd. | Wood Routers, Laser Engraving Machines | Not specified | 100% | ≤6h | - | $5,599–8,999 | Worktable size, spindle configuration |

| Jinan Quick-Fulltek CNC Machinery Co., Ltd. | Wood Routers, Panel Processing Lines | US $80,000+ | 100% | ≤8h | <15% | $2,300–160,000 | Mini desktop to industrial-scale systems |

| Roctech Machinery Co.,Ltd. | Wood Routers, Laser Cutters | US $200,000+ | 100% | ≤4h | 20% | $3,699–22,800 | High-rigidity frames, multifunctional setups |

| Foshan Shunde Ruinuo CNC Equipment Co., Ltd. | Panel Woodworking Machinery | Not specified | 100% | ≤7h | - | $21,000–46,800 | Auto-loading/unloading, swing head |

| Jinan TechPro CNC Equipment Co., Ltd. | Wood ATC Nesting CNC, 5-Axis Routers | US $670,000+ | 100% | ≤2h | 33% | $9,500–32,000 | Full parameter customization, CAD/CAM support |

Performance Analysis

Jinan TechPro CNC stands out with the highest recorded online revenue (US $670,000+) and fastest average response time (≤2h), paired with a 33% reorder rate—indicating strong customer retention and service reliability. Roctech Machinery demonstrates balanced performance with competitive pricing and mid-tier customization depth. Foshan Shunde Ruinuo focuses on premium industrial models, including auto-load systems priced above $26,000, targeting large-scale production environments. Jinan Quick-Fulltek offers the widest price range, suggesting flexibility from entry-level desktop units to high-end production machines. All top-tier suppliers maintain 100% on-time delivery records, underscoring operational consistency across the segment.

FAQs

How to verify ATC CNC router supplier reliability?

Evaluate response time consistency, reorder rates, and transaction volume as indicators of trustworthiness. Request factory videos or virtual audits to confirm in-house production capabilities. Validate technical claims regarding spindle brands, control systems (e.g., Syntec, NC Studio), and structural components like welded steel beds versus bolted frames.

What is the typical MOQ and lead time?

Minimum Order Quantity is generally 1 set, facilitating sample validation and small-batch procurement. Lead times range from 20–40 days depending on complexity, with additional 7–14 days for international shipping via sea freight. Air freight options are limited due to machine weight and crating requirements.

Can suppliers provide custom configurations?

Yes, most suppliers support extensive customization including non-standard table sizes, dual spindles, conveyor integration, and specialized software interfaces. TechPro and Ruinuo CNC explicitly list 5-axis, rotary, and auto-loading features, indicating advanced engineering support for complex applications.

Do manufacturers offer after-sales support?

Leading suppliers provide remote troubleshooting, training via video conferencing, and spare parts supply chains. Some include installation guides, wiring diagrams, and PLC code documentation. Warranty periods typically range from 12–24 months on core components.

How are shipments handled for heavy machinery?

Full container load (FCL) sea freight is standard for single or bulk orders. Suppliers typically quote FOB terms; buyers arrange final destination logistics. Proper crating, moisture protection, and shock indicators are essential to ensure safe transit. CIF terms may be negotiated for first-time importers.