China Ptp Cnc Router Customized

1/7

1/7

1/18

1/18

1/10

1/10

1/20

1/20

1/3

1/3

1/5

1/5

1/39

1/39

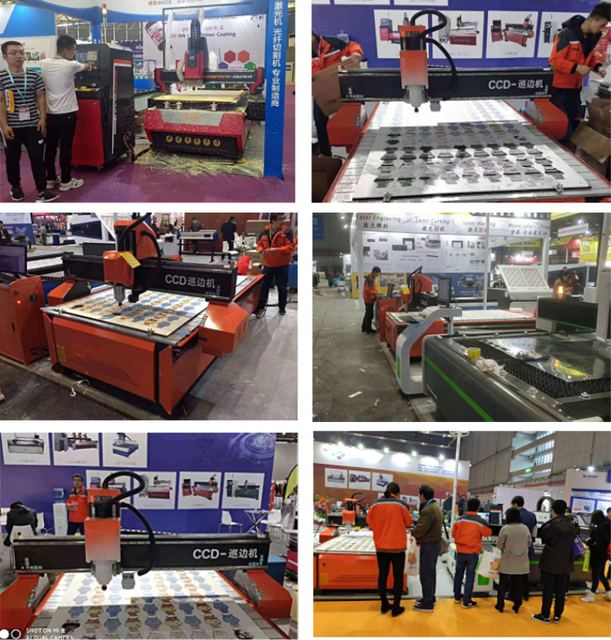

About china ptp cnc router customized

Where to Find PTP CNC Router Suppliers in China?

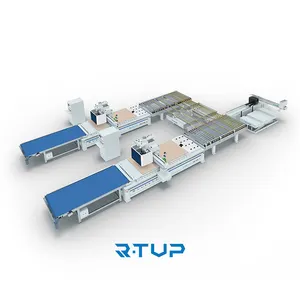

China is a global manufacturing hub for PTP (Point-to-Point) CNC routers, with Shandong province emerging as a core production cluster. Key cities like Jinan host concentrated networks of industrial machinery suppliers specializing in woodworking automation equipment. These regions benefit from vertically integrated supply chains—spanning structural steel fabrication, servo motor assembly, and control system integration—enabling cost efficiencies of 20–35% compared to European or North American manufacturers.

The ecosystem supports both standardized and fully customized machine builds, with many suppliers operating end-to-end production facilities within 5–10 km radii. This proximity reduces component lead times and enhances quality traceability. Buyers can expect typical delivery windows of 30–45 days for custom-configured units, supported by modular design platforms that allow rapid reconfiguration of worktable sizes, spindle types, and tool-changing systems. The region’s specialization in industrial automation ensures access to engineering talent and technical after-sales support, critical for long-term operational reliability.

How to Choose a Reliable PTP CNC Router Supplier?

Selecting the right supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm suppliers offer ISO 9001-certified quality management systems as a baseline. For international deployments, CE marking is essential for compliance with EU safety standards. Validate specifications for core components: ball screws (C3 grade or higher), servo motors (preferably Japanese or European brands), and spindles (power output ≥4.5 kW for heavy-duty applications). Request documentation on spindle runout testing (<0.01 mm) and dynamic load balancing.

Production Infrastructure Assessment

Evaluate key operational indicators:

- Minimum factory area exceeding 3,000m² to ensure scalable output

- In-house machining capabilities for frame welding, precision leveling, and electrical cabinet assembly

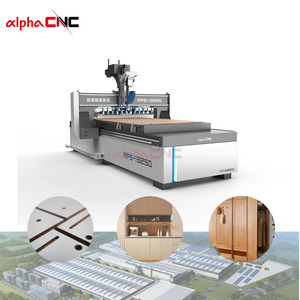

- Dedicated R&D teams supporting customization (e.g., ATC integration, CCD camera alignment, vacuum table design)

- On-time delivery performance >95% and response time under 8 hours

Cross-reference these metrics with verifiable transaction data, such as online revenue trends and reorder rates, to assess business stability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as third-party escrow until final inspection clearance. Prioritize suppliers with documented quality control protocols—including pre-shipment testing reports and video walkthroughs of completed machines. Conduct sample validation to benchmark cutting accuracy (±0.05 mm over 1 m), noise levels (<75 dB), and thermal stability during extended operation.

What Are the Leading PTP CNC Router Suppliers in China?

| Company Name | Location | Verified Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Scope | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Jinan Spower Machinery Technology Co., Ltd. | Jinan, Shandong | Multispecialty Supplier | US $180,000+ | 100% | ≤2h | 50% | Spindle type, tool changer, safety system, color, dimensions, material size | 1 set |

| Jinan TechPro CNC Equipment Co., Ltd. | Jinan, Shandong | Multispecialty Supplier | US $670,000+ | 100% | ≤1h | 28% | Working size, dust aspiration, ATC, spindle power, cooling, labeling, CAD/CAM compatibility | 1 set |

| Shandong U-May Cnc Technology Co., Ltd. | Shandong | Not specified | US $1,100,000+ | 95% | ≤8h | 54% | Limited customization; broader product range including laser and plasma cutters | 1 set |

| Jinan Bcamcnc Machinery Co., Ltd. | Jinan, Shandong | Brand Holder | US $2,100,000+ | 100% | ≤2h | 33% | Automatic lubrication, vacuum pump, double dust collector, four-axis, tool changer, spindle configuration | 1 set |

| Jinan Quick-Fulltek CNC Machinery Co., Ltd. | Jinan, Shandong | Not specified | US $70,000+ | 100% | ≤8h | <15% | Standard models with limited customization; focus on entry-level routers | 1–2 sets |

Performance Analysis

Jinan-based suppliers dominate in responsiveness and technical depth, with three of five achieving sub-2-hour average reply times. Jinan Bcamcnc leads in transaction volume (US $2.1M+ annual online revenue), indicating strong market confidence and export scalability. Shandong U-May exhibits the highest reorder rate (54%), suggesting effective post-sale service despite lower technical specialization in PTP systems. Suppliers like Jinan Spower and TechPro offer extensive customization—ranging from spindle drive systems to active safety packaging—making them ideal for buyers requiring application-specific configurations. Notably, all top-tier suppliers support single-unit MOQs, reducing procurement risk for pilot deployments.

FAQs

What certifications should PTP CNC router suppliers have?

Essential certifications include ISO 9001 for quality management and CE marking for compliance with European health, safety, and environmental standards. Suppliers should provide test reports for EMC, LVD, and mechanical safety directives. For U.S. buyers, confirmation of OSHA-compatible guarding and emergency stop systems is recommended.

What is the typical lead time for customized PTP CNC routers?

Custom-built units generally require 30–45 days from order confirmation to shipment. Complex integrations—such as multi-head setups, linear tool changers, or vision-guided drilling—may extend timelines to 60 days. Expedited builds (20–25 days) are available from high-capacity suppliers at a premium.

Can suppliers accommodate small batch orders?

Yes, most leading suppliers accept minimum orders of one set, particularly for customized configurations. However, unit pricing decreases significantly at volumes above five sets due to fixed engineering and setup costs.

What customization options are commonly offered?

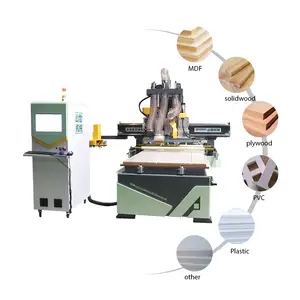

Key configurable parameters include working table size (e.g., 1325, 1530), spindle power (3–9 kW), tool changer type (manual, linear ATC, rotary), dust collection integration, vacuum zones, control systems (Syntec, NC Studio), and safety features (light curtains, door interlocks). Advanced options include CCD cameras for drill positioning and mist cooling systems.

How should buyers validate machine performance before purchase?

Request a production sample or live demo video showing actual cutting cycles on relevant materials (MDF, plywood, solid wood). Verify positional repeatability using dial indicator tests and inspect weld integrity on the machine bed. Insist on a pre-shipment inspection report detailing no-load run tests, axis calibration, and electrical safety checks.