China 3d Woodworking Cnc Router Customized

1/16

1/16

1/5

1/5

CN

CN

1/5

1/5

1/3

1/3

1/3

1/3

1/16

1/16

1/3

1/3

1/16

1/16

1/3

1/3

1/3

1/3

1/3

1/3

1/28

1/28

1/1

1/1

1/3

1/3

About china 3d woodworking cnc router customized

Where to Find 3D Woodworking CNC Router Suppliers in China?

China remains the global epicenter for 3D woodworking CNC router manufacturing, with key production clusters concentrated in Shandong and surrounding industrial regions. These zones host vertically integrated supply chains encompassing precision machining, servo motor integration, and control system assembly, enabling rapid prototyping and scalable production. Shandong, in particular, is home to over 70% of specialized CNC machinery exporters, supported by mature logistics networks that ensure efficient global shipment via Qingdao and Yantai ports.

The region’s ecosystem allows manufacturers to offer both standardized and fully customized 3D CNC routers with lead times typically ranging from 15 to 30 days. Local suppliers benefit from proximity to steel, linear rail, and spindle component producers, reducing material costs by 18–25% compared to non-integrated markets. Buyers gain access to flexible MOQs—often as low as one set—and advanced customization options including multi-axis configurations, automatic tool changers (ATC), vacuum tables, and integrated dust collection systems.

How to Choose a Reliable 3D Woodworking CNC Router Supplier?

Selecting a qualified supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities Verification

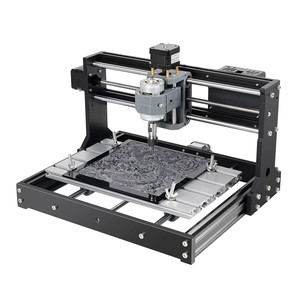

Confirm machine specifications align with intended applications: working area (e.g., 1325, 1530, 2030 formats), spindle power (1.5kW–7kW), axis configuration (3-axis, 4-axis, or 5-axis), and control systems (NC Studio, DSP, Mach3). Prioritize suppliers offering CE compliance and ISO 9001 certification as baseline indicators of quality management. For international buyers, verify compatibility with local voltage standards (220V/380V) and software language support (English interface).

Production & Customization Capacity

Assess the manufacturer's ability to deliver tailored solutions based on these criteria:

- In-house engineering teams capable of modifying machine dimensions, spindle types, tool changers, and safety systems

- Proven experience integrating auxiliary functions such as CCD cameras, oscillating knives, laser alignment, and water cooling systems

- Customization scope covering material type (wood, MDF, acrylic, HDPE), engraving depth, and automation level (nesting lines, ATC)

- Evidence of functional testing protocols, including dry runs and sample processing under real-world conditions

Supplier Performance Metrics

Leverage verifiable performance data to assess reliability:

- On-time delivery rate ≥95%

- Reorder rate >25% indicating customer retention

- Average response time ≤1 hour for inquiry handling

- Transparent documentation of after-sales service, warranty terms (typically 12–24 months), and technical support availability

Transaction Security Measures

Insist on secure payment structures such as escrow or milestone-based disbursements. Request video audits of factory operations and request physical or digital samples before full-scale orders. Validate export experience through shipping records and customs documentation, particularly for complex machinery subject to import regulations.

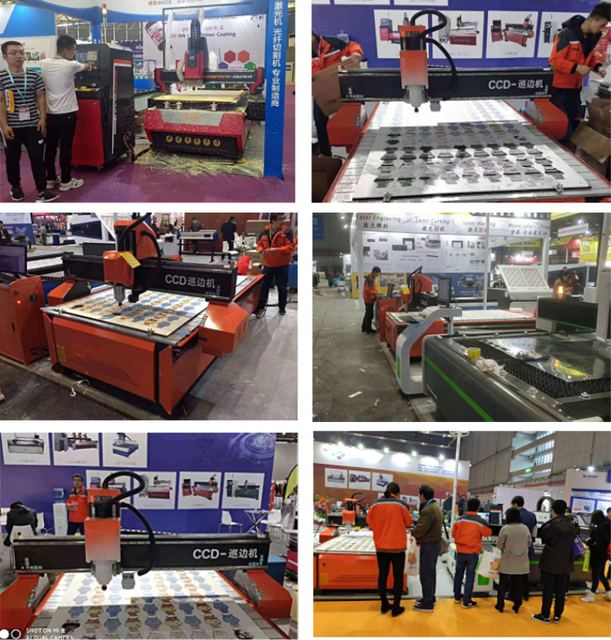

What Are the Leading 3D Woodworking CNC Router Suppliers in China?

| Company Name | Verified Status | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Range | Price Range (USD) | Customization Level |

|---|---|---|---|---|---|---|---|---|

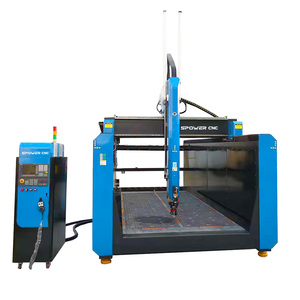

| Jinan Spower Machinery Technology Co., Ltd. | Multispecialty Supplier | US $180,000+ | 100% | ≤1h | 54% | 5 models | $6,500–$9,999 | High (tool changer, spindle drive, safety systems, color, dimensions) |

| Shandong UMW Technology Co., Ltd. | Multispecialty Supplier | US $680,000+ | 100% | ≤1h | 32% | 5 models | $900–$57,600 | Medium-High (spindles, material size, packaging, engraving specs) |

| Jinan Mingshi Machinery Equipment Co., Ltd. | Custom Manufacturer | US $270,000+ | 100% | ≤1h | 25% | 5 models | $2,055–$7,250 | Extensive (vacuum tables, ATC, rotating attachments, multiple heads, software) |

| DEZHOU YUDIAO MECHANICAL EQUIPMENT CO., LTD. | Custom Manufacturer | US $20,000+ | 66% | ≤1h | 16% | 5 models | $1,550–$9,000 | Basic (color, material size, logo, packaging) |

| Jinan Sign Cnc Equipment Co., Ltd. | Not Specified | US $640,000+ | 100% | ≤1h | <15% | 5 models | $4,500–$13,500 | Medium (tool changers, spindle types, feeding height, motor configuration) |

Performance Analysis

Jinan Spower stands out with the highest reorder rate (54%) and consistent high-end pricing, suggesting strong customer satisfaction in customization and build quality. Shandong UMW and Jinan Sign demonstrate robust online revenue and perfect on-time delivery, indicating reliable fulfillment despite broader market competition. Jinan Mingshi offers extensive functional customization—including ATC nesting lines and multi-head setups—making it ideal for furniture and cabinetry manufacturers requiring automation. DEZHOU YUDIAO provides entry-level pricing but shows lower on-time delivery performance (66%), which may pose risks for time-sensitive projects. Buyers seeking premium 5-axis or industrial-grade systems should prioritize suppliers with documented R&D capabilities and higher investment brackets ($9,000+).

FAQs

What is the typical minimum order quantity (MOQ) for 3D woodworking CNC routers?

Most Chinese suppliers list an MOQ of 1 set, allowing small businesses and workshops to procure without volume commitments. Bulk discounts are commonly available for orders exceeding three units.

How long does it take to receive a customized CNC router?

Standard production lead time ranges from 15 to 25 days post-design confirmation. Complex configurations involving 5-axis integration, custom software, or automated feeding systems may extend to 35 days. Shipping adds 10–25 days depending on destination and mode (sea or air freight).

Can suppliers provide pre-shipment testing and factory audits?

Yes, reputable manufacturers offer live video demonstrations of machine operation, including test cuts on specified materials. Some provide remote access to control interfaces for validation. On-site or third-party inspection services can be arranged prior to dispatch.

Do these suppliers support international voltage and language requirements?

Most suppliers design machines for dual-voltage compatibility (220V/380V, 50/60Hz) and include English-language control panels and software (e.g., NC Studio, DSP). Firmware localization and multilingual technical manuals are standard upon request.

What kind of after-sales support can be expected?

Leading suppliers offer 12–24 month warranties covering core components (spindle, drivers, control board). Remote troubleshooting via TeamViewer or similar platforms is common. Spare parts kits and installation guides are typically included. Extended support may involve on-site technician deployment at additional cost.