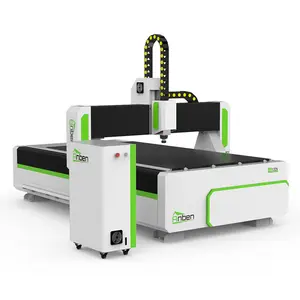

Cnc Router Machine China

About cnc router machine china

Where to Find CNC Router Machine Suppliers in China?

China remains the global epicenter for CNC router machine manufacturing, with Shandong and Guangdong provinces emerging as primary industrial hubs. Shandong, particularly cities like Jinan and Qingdao, hosts a dense cluster of machinery manufacturers specializing in industrial-grade wood and metal cutting systems. These regions benefit from vertically integrated supply chains—encompassing casting, linear rail production, spindle fabrication, and control system integration—reducing component procurement lead times by up to 40%. Guangdong’s Shenzhen-based suppliers focus on compact, precision-oriented models tailored for small-scale workshops and prototyping labs.

The concentration of engineering talent and ancillary industries enables rapid prototyping and scalable production. Facilities in these zones typically operate automated assembly lines supported by in-house R&D teams, achieving standard order fulfillment within 20–35 days. Buyers gain access to cost efficiencies driven by localized sourcing, with production costs averaging 25–35% below those of European or North American equivalents. The ecosystem supports both high-volume procurement and customized configurations, including ATC (Automatic Tool Changer), multi-head setups, and hybrid metal-wood processing capabilities.

How to Choose CNC Router Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international standards such as CE, ISO 9001, and where applicable, RoHS. For export markets, CE certification is essential for customs clearance and regulatory compliance. Request documentation on spindle runout testing, ball screw calibration, and gantry alignment procedures. Confirm use of hardened square guide rails or linear rails rated for ≥5,000 hours of continuous operation.

Production Capability Assessment

Evaluate core infrastructure indicators:

- Minimum factory area exceeding 3,000m² to ensure stable output capacity

- In-house machining centers for frame milling and stress-relieved bed construction

- Dedicated calibration stations using laser interferometers for axis accuracy verification

Cross-reference declared delivery performance (target ≥96%) with actual transaction volume and reorder rates to assess reliability.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services that release funds only upon equipment verification. Prioritize suppliers offering sample units or factory inspection access via video audit. Conduct functional testing on delivered machines, validating positional accuracy (±0.05mm), repeatability, and spindle stability under load. Confirm inclusion of OEM control systems (e.g., Syntec, Mach3, NC Studio) with multilingual interface support.

What Are the Leading CNC Router Machine Suppliers in China?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Jinan Ginchoor Cnc Equipment Co., Ltd. | Shandong, CN | Wood Routers (212), Laser Cutters (335) | US $70,000+ | 100% | ≤1h | 66% | $1,980–$9,000 | Limited; focused on standard 1325/1390 models |

| Jinan AccTek Machinery Co., Ltd. | Jinan, CN | Wood & Metal Routers, ATC Systems | US $860,000+ | 100% | ≤3h | <15% | $1,000–$9,200 | Extensive: water-cooled spindles, T-slot tables, auto-lubrication, gear rack drives |

| Shandong Honda Benk Cnc Smart Equipment Co., Ltd. | Shandong, CN | Nesting Machines, Panel Production Lines | US $80,000+ | 100% | ≤3h | <15% | $3,500–$17,580 | High: linear ATC, heavy-duty frames, full automation integration |

| Alpha Cnc Co., Ltd. | Shandong, CN | ATC Routers, Vacuum Table Models | US $1,400,000+ | 100% | ≤1h | 58% | $1,500–$2,500 | Moderate: spindle power options, cooling methods, tool zones, packaging specs |

| Shenzhen Twotrees Technology Co., Ltd. | Guangdong, CN | Mini CNC Routers, 3D Engraving Systems | US $190,000+ | 96% | ≤5h | 21% | $119.90–$1,450 | Basic: engraving depth, motor type, laser add-ons, color variants |

Performance Analysis

Jinan Ginchoor and Alpha CNC demonstrate strong buyer retention (66% and 58% reorder rates respectively), indicating consistent quality and responsive service. Alpha CNC stands out with the highest online revenue, reflecting broad market penetration and efficient digital sales operations. Jinan AccTek offers the widest technical customization range, suitable for buyers requiring specialized worktables, drive systems, or cooling configurations. Shandong Honda Benk targets mid-to-high-end industrial clients with premium nesting and panel processing lines priced above $10,000. In contrast, Shenzhen Twotrees serves entry-level and educational markets with sub-$1,500 desktop models, though response times lag behind Shandong-based peers. All top-tier suppliers maintain 100% on-time delivery records except Twotrees (96%), underscoring logistical discipline in northern manufacturing clusters.

FAQs

How to verify CNC router machine supplier reliability?

Cross-validate certifications through official databases. Request evidence of in-house quality control processes, including final assembly checklists and 24-hour burn-in tests. Analyze customer feedback focusing on post-delivery technical support and spare parts availability.

What is the typical lead time for CNC router orders?

Standard configurations ship within 15–25 days after deposit confirmation. Customized systems with ATC or dual-spindle setups require 30–45 days. Air freight delivery adds 5–10 days globally; sea freight takes 25–40 days depending on destination port.

Do suppliers support global shipping and import compliance?

Yes, established exporters provide FOB, CIF, and DDP shipping terms. Confirm inclusion of CE-marked electrical cabinets and compliance with IEC 60204-1 safety standards for machinery. Suppliers typically handle export documentation and container loading for sea shipments.

Is customization available for CNC router machines?

Most suppliers offer configurable options including spindle power (3–15kW), table type (T-slot or vacuum), guide rail brand (HIWIN, PMI), control system (Mach3, DSP), and drive mechanism (servo vs stepper). High-end models support full automation integration and tool magazine expansion.

Can I request a sample or pre-shipment inspection?

Sample units are available at incremental cost, typically 1.5x unit price. Buyers may conduct third-party inspections prior to shipment or arrange virtual factory audits to review assembly and testing procedures. Some suppliers offer ready-to-ship units with expedited 7-day dispatch.