Cnc Machine From China

CN

CN

About cnc machine from china

Where to Find CNC Machine Suppliers from China?

China remains the world’s leading producer of CNC machines, with manufacturing hubs concentrated in Shandong, Shaanxi, and Zhejiang provinces. These regions host vertically integrated industrial ecosystems that support end-to-end production—from casting and machining to final assembly—enabling competitive pricing and scalable output. Shandong alone accounts for over 40% of China’s CNC machine tool exports, driven by its proximity to steel suppliers and major ports like Qingdao, which reduce logistics costs by 12–18% compared to inland regions.

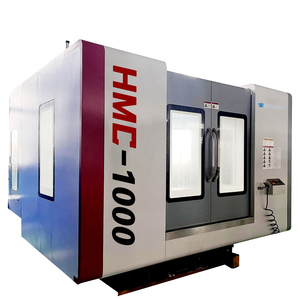

Suppliers in these clusters benefit from mature supply chains for critical components such as ball screws, spindles, and CNC controllers, often sourced domestically from brands like GSK and Huazhong. This localization supports faster turnaround times, with standard models typically delivered within 30–45 days after order confirmation. Buyers also gain access to broad product ranges, including vertical machining centers, CNC lathes, gantry mills, and 5-axis systems, with prices ranging from $9,800 for compact 3-axis units to over $280,000 for high-precision multi-axis configurations.

How to Choose CNC Machine Suppliers from China?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional dimensions:

Technical & Production Capability

Assess whether suppliers maintain in-house machining, assembly, and testing facilities. Preferred partners operate factory areas exceeding 5,000m² with dedicated R&D teams focused on motion control optimization and structural rigidity. Key indicators include ownership of precision measurement equipment (e.g., laser interferometers) and integration of advanced control systems (Fanuc, Siemens, SYNTEC). Suppliers listing over 200 active CNC-related products demonstrate sustained production capacity and market presence.

Quality Assurance and Compliance

While ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery rates of 100% across multiple suppliers suggest adherence to formal quality management systems. For export compliance, verify CE marking or regional equivalents required for operation in target markets. Request documentation for spindle runout tests, positioning accuracy validation (±0.005mm or better), and thermal stability protocols, especially for high-speed or heavy-duty models.

Transaction Reliability Metrics

Prioritize suppliers with verifiable performance indicators:

- On-time delivery rate ≥98%

- Average response time ≤2 hours

- Reorder rate >15% indicating customer retention

- Third-party revenue verification (e.g., platform-reported sales exceeding US $100,000 annually)

Cross-reference digital profiles with direct communication tests and request facility walkthrough videos to validate claims about automation levels and inventory management.

What Are the Top CNC Machine Suppliers from China?

| Company Name | Location | Main Product Lines | Listing Volume | On-Time Delivery | Avg. Response | Revenue Evidence | Reorder Rate | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shaanxi Jingwei Hongbo Cnc Equipment Co., Ltd. | Shaanxi, CN | Machining Centre, CNC Milling Machines | 2,175+ | 100.0% | ≤1h | US $100+ | <15% | $19,999–71,541 |

| Taiyun (Shandong) Cnc Machine Tool Co., Ltd. | Shandong, CN | Vertical Lathes, VMC Series | 5+ | 100.0% | ≤2h | US $1,000+ | Not reported | $15,400–37,000 |

| Shandong Selection Machinery Co., Ltd. | Shandong, CN | Machining Centre, CNC Lathe, EDM | 273+ | 100.0% | ≤1h | Not reported | Not reported | $11,000–88,888 |

| Shandong Mainland Cnc Equipment Co., Ltd | Shandong, CN | CNC Lathe, Machining Centre | 1,440+ | 100.0% | ≤3h | US $180,000+ | 22% | $9,800–35,900 |

| Ningbo Kula Precision Machinery Co., Ltd. | Zhejiang, CN | 5-Axis Machining Centers, Gantry Mills | 5+ | 100.0% | ≤2h | Not reported | Not reported | $34,000–284,150 |

Performance Analysis

Shaanxi Jingwei Hongbo and Shandong Mainland exhibit strong commercial traction, supported by high listing volumes and third-party revenue validation. Shandong-based suppliers dominate responsiveness, with three out of five achieving sub-2-hour average reply times. Ningbo Kula stands out for高端制造 capability, offering 5-axis vertical machining centers priced above $280,000, indicating investment in high-precision spindles and linear guides. Suppliers like Shandong Selection Machinery offer wide configurability, including large-stroke VMC1160 models and 4-axis integrated centers, suitable for aerospace and mold-making applications. Reorder rate of 22% at Shandong Mainland suggests reliable post-sale service and machine durability.

FAQs

What are typical MOQ and lead times for CNC machines from China?

Minimum order quantity is generally 1 unit, allowing low-volume procurement for testing or specialized use. Lead times range from 30 to 45 days for standard configurations. Customized or high-power models may require 60+ days depending on controller availability and structural modifications.

Do Chinese CNC machine suppliers support customization?

Yes, most suppliers offer configuration options for control systems (Fanuc, Siemens, GSK), spindle speed (8,000–24,000 RPM), axis count (3 to 5-axis), and work envelope dimensions. Some provide OEM services including logo branding, color schemes, and packaging labels. Confirm software compatibility (e.g., CAD/CAM integration) and electrical specifications (380V/50Hz vs. 480V/60Hz) during technical alignment.

How to verify CNC machine quality before shipment?

Request pre-shipment inspection reports detailing no-load running tests, positional repeatability checks, and geometric accuracy measurements. Third-party inspectors (e.g., SGS, Bureau Veritas) can conduct on-site audits. Alternatively, arrange remote video testing of machine startup, tool change cycles, and dry runs using G-code simulations.

Are spare parts and technical support included?

Support varies by supplier. Leading vendors provide basic toolkits, lubrication charts, and PLC diagrams. Extended warranties (1–2 years) and remote troubleshooting via TeamViewer or similar platforms are increasingly common. Clarify availability of replacement spindles, drive motors, and control boards prior to purchase.

What are the shipping options for CNC machines?

Machines are typically shipped FOB or CIF via sea freight due to weight (3–20 metric tons) and crate dimensions. Flatbed containers are used for larger gantry or vertical turning centers. Air freight is feasible only for compact desktop CNC units. Ensure proper crating with anti-vibration mounts and moisture protection for ocean transit.