China Cnc Lathe Machine

Top sponsor listing

Top sponsor listing

CN

CN

About china cnc lathe machine

Where to Find CNC Lathe Machine Suppliers in China?

China remains a global manufacturing hub for CNC lathe machines, with key production clusters concentrated in Shandong, Liaoning, and Shanghai. These regions host vertically integrated industrial ecosystems combining precision engineering, casting, and CNC component fabrication. Shandong province, home to heavy machinery manufacturers like Shandong Zhongxin Heavy Industries, benefits from proximity to steel suppliers and port infrastructure, enabling cost reductions of 15–25% compared to non-integrated supply chains. Dalian in Liaoning specializes in high-precision automated lathes, leveraging decades of machining expertise and access to skilled technical labor.

The regional advantage extends to logistics and scalability. Suppliers within these zones operate facilities ranging from 5,000m² to over 24,000m², supporting batch production and rapid fulfillment. Integrated supplier networks allow for shorter lead times—typically 30–60 days for standard models—with many offering customization without significant delays. Buyers benefit from localized sourcing of critical components such as spindles, tool turrets, and control systems, reducing dependency on imported parts and enhancing price competitiveness.

How to Choose CNC Lathe Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation based on verifiable performance metrics and operational capabilities:

Technical and Operational Compliance

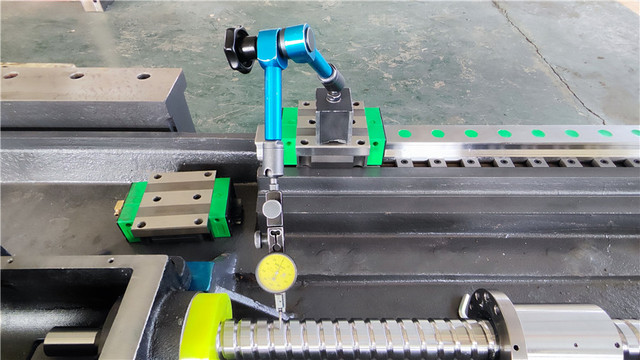

Prioritize suppliers with documented adherence to international quality standards. While ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery rates above 95% serve as a proxy for process reliability. For export markets requiring regulatory compliance (e.g., CE, FCC), request formal declarations and test reports for electrical and mechanical safety. Validate spindle runout tolerances, positioning accuracy, and surface finish specifications against industry benchmarks such as ISO 230-2.

Production Capacity Verification

Assess infrastructure maturity through the following indicators:

- Facility size exceeding 3,000m² to support dedicated assembly lines

- In-house machining capabilities for critical subsystems (e.g., bed casting, guideways)

- Customization capacity including live tooling, bar feeders, dual chucks, and color coding

- Integration of major control systems (Fanuc, Siemens, Mitsubishi) across product lines

Cross-reference online revenue estimates (where available) with order volume consistency. Suppliers reporting annual online revenues above US $960,000 demonstrate sustained market presence.

Transaction and Quality Safeguards

Utilize secure payment methods that include inspection milestones, especially for first-time engagements. Request pre-shipment inspection reports or third-party audits (e.g., SGS, TÜV) to verify machine calibration and build quality. Sample testing is recommended—evaluate turning accuracy, thermal stability, and vibration levels under load before scaling procurement.

What Are the Top CNC Lathe Machine Suppliers in China?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options | Min. Order Value |

|---|---|---|---|---|---|---|---|---|

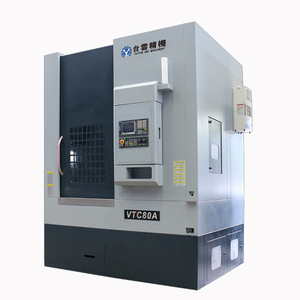

| Shandong Zhongxin Heavy Industries Co., Ltd. | Shandong, CN | CNC Lathe, Machining Centre, Milling Machines | 75% | ≤1h | US $100,000+ | <15% | Color, turret, chuck, material size, live tools, labeling | $6,200+ |

| Dalian Jinfang International Trade Co., Ltd. | Liaoning, CN | CNC Lathe, CNC Milling Machines | 100% | ≤1h | Data Unavailable | No Data | Limited (model-specific features) | $5,300+ |

| Shanghai Sihao Machinery Equipment Co., Ltd. | Shanghai, CN | Manual Lathe, Mini CNC, Heat Press | 98% | ≤5h | US $1,700,000+ | <15% | Miniature models with basic configurations | $398+ |

| Jinan Kasen Cnc Equipment Co., Ltd. | Shandong, CN | Metal CNC Lathes, Swiss-type, Inclined Bed | 100% | ≤1h | US $960,000+ | <15% | Full range: diameter, material, control system, feeder, packaging | $3,500+ |

| Shanghai Gubot Automobile Technology Co., Ltd. | Shanghai, CN | Alloy Wheel Repair CNC Lathe, Tire Changers | 95% | ≤6h | US $440,000+ | 16% | Specialized wheel repair configurations | $12,000+ |

Performance Analysis

Dalian Jinfang and Jinan Kasen lead in operational reliability with 100% on-time delivery and sub-hour response times, indicating robust order management systems. Jinan Kasen stands out for comprehensive customization, supporting configuration changes across spindle design, automation integration, and control interfaces—critical for OEM integration. Shandong Zhongxin offers broadest product diversity but shows a lower reorder rate, suggesting potential gaps in post-sale service or long-term satisfaction.

Shanghai-based suppliers cater to niche segments: Sihao focuses on entry-level mini lathes ideal for prototyping and education, while Gubot specializes in automotive-specific CNC lathes for alloy wheel refurbishment. Their higher minimum order values reflect application-specific engineering and lower economies of scale. Buyers seeking standardized horizontal or inclined-bed CNC lathes should prioritize suppliers with Fanuc or Siemens-compatible controls and documented testing procedures.

FAQs

How to verify CNC lathe machine supplier reliability?

Evaluate on-time delivery history, response time consistency, and transaction volume. Request facility videos or virtual audits to confirm in-house production capabilities. Verify compatibility of control systems and availability of technical documentation in English.

What is the typical lead time for CNC lathe machines?

Standard models are typically delivered within 30–45 days after order confirmation. Custom configurations involving live tooling, special chucks, or unique bed designs may extend lead times to 60 days depending on complexity.

Do suppliers offer customization options?

Yes, most suppliers provide configurable options including spindle speed, chuck type, tool turret layout, bar feeding systems, and control panels. High-end models support integration with robotic loaders and IoT-enabled monitoring systems.

What are common MOQ and pricing ranges?

Minimum order quantities are typically 1 set. Entry-level mini CNC lathes start at $398, mid-range flat-bed models range from $5,000–$10,000, while high-capacity inclined-bed or Swiss-type lathes range from $15,000–$21,500.

Can suppliers handle international shipping and customs clearance?

Yes, experienced exporters manage global logistics via FOB or CIF terms. Confirm whether packaging meets international export standards and if necessary certifications (CE, EAC) are provided for destination compliance.