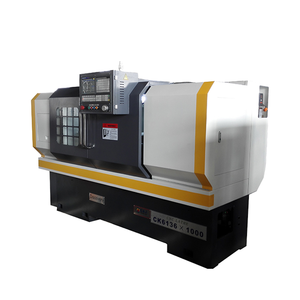

Cnc Lathe Machine China

1/9

1/9

CN

CN

1/22

1/22

1/20

1/20

1/12

1/12

1/9

1/9

1/9

1/9

1/21

1/21

About cnc lathe machine china

Where to Find CNC Lathe Machine Suppliers in China?

China remains the world’s largest manufacturing hub for CNC lathe machines, with key industrial clusters concentrated in Shandong, Shanghai, and Liaoning provinces. These regions host vertically integrated supply chains that support rapid production scaling and cost-efficient machining solutions. Shandong, home to Jinan and Taian, specializes in high-precision flat-bed and inclined-bed CNC lathes, leveraging proximity to steel and casting suppliers to reduce raw material costs by 15–25%. Shanghai's machinery corridor focuses on compact and multi-functional models, particularly mini CNC lathes for small-part machining, benefiting from advanced electronics integration and automation expertise.

The Dalian region in Liaoning supports export-oriented manufacturers with access to major seaports, enabling streamlined logistics for global buyers. Collectively, these zones feature mature ecosystems where component sourcing, precision machining, assembly, and quality control occur within tightly coordinated networks. Buyers benefit from shorter lead times—typically 30–45 days for standard configurations—and flexible MOQs starting at one unit. Localized production also allows for competitive pricing, with entry-level models available from $395 and high-performance variants exceeding $50,000, reflecting broad market segmentation.

How to Choose CNC Lathe Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm whether the supplier offers machines aligned with required specifications: bed type (flat or inclined), spindle configuration, chuck size, and control system (Fanuc, Siemens, or domestic brands). Prioritize suppliers listing CNC milling integration or Swiss-type lathes as evidence of engineering maturity. For specialized applications such as alloy wheel repair or micro-precision turning, verify dedicated product lines and customization capabilities.

Production and Quality Assurance

Assess manufacturing infrastructure using available performance indicators:

- On-time delivery rate ≥98% indicates reliable production planning

- Response time ≤2 hours reflects strong customer service protocols

- In-house R&D and customization options signal technical agility

- Compliance with ISO 9001 or CE standards ensures baseline quality management

Cross-reference online revenue metrics (where available) as a proxy for market presence and order volume capacity. Suppliers with diversified product portfolios may offer better after-sales support and spare parts availability.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate risk. Request test reports for critical components including spindle accuracy, tool turret repeatability, and servo response. Where feasible, conduct virtual factory audits via video tours to validate claims about equipment, workforce, and quality control processes. Insist on pre-shipment inspections, especially for first-time partnerships.

What Are the Leading CNC Lathe Machine Suppliers in China?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Key Product Range |

|---|---|---|---|---|---|---|---|---|

| Jinan Kasen Cnc Equipment Co., Ltd. | Shandong, CN | Custom Manufacturer | US $960,000+ | 100% | ≤1h | <15% | Yes | Horizontal flat-bed, hydraulic chuck, inclined-bed, Swiss-type |

| Shanghai Sihao Machinery Equipment Co., Ltd. | Shanghai, CN | - | US $1,700,000+ | 98% | ≤5h | <15% | No | Mini metal/wood lathe, variable speed benchtop models |

| Shanghai Gubot Automobile Technology Co., Ltd. | Shanghai, CN | - | US $440,000+ | 95% | ≤6h | 16% | No | Alloy wheel repair CNC lathes, rim restoration systems |

| Dalian Jinfang International Trade Co., Ltd. | Liaoning, CN | - | - | 100% | ≤1h | - | No | CK-series flat-bed CNC lathes, Fanuc-controlled models |

| Taian Best Machinery Co., Ltd. | Shandong, CN | Multispecialty Supplier | US $70,000+ | 100% | ≤2h | 100% | Yes | CK6140/CK6163 series, vertical CNC lathes (VTC850) |

Performance Analysis

Jinan Kasen and Taian Best demonstrate exceptional reliability with 100% on-time delivery and sub-2-hour response times, making them suitable for time-sensitive procurement. Taian Best stands out with a 100% reorder rate, indicating high client satisfaction despite lower online revenue. Jinan Kasen offers the widest customization scope, including control systems, feeders, and branding, ideal for OEM integrators. In contrast, Shanghai Sihao leads in volume sales (US $1.7M+ revenue) with ultra-low-cost mini CNC lathes, targeting educational institutions and small workshops. Dalian Jinfang, while lacking public revenue data, maintains top-tier delivery performance and offers mid-to-high-end CK-series machines with Fanuc compatibility. Shanghai Gubot occupies a niche in automotive wheel refurbishment, though its 95% on-time rate and 6-hour response window suggest moderate scalability.

FAQs

What is the typical MOQ for CNC lathe machines from Chinese suppliers?

Most suppliers list a minimum order quantity of 1 set, allowing flexibility for individual buyers, distributors, and pilot testing. Some listings require 2–3 units for discounted pricing, particularly for mini or specialized models.

How long does it take to receive a CNC lathe machine from China?

Standard production lead time ranges from 30 to 45 days after order confirmation. Shipping via sea freight adds 25–40 days depending on destination. Air freight reduces transit time to 5–10 days but is typically reserved for urgent spare parts due to high costs.

Can I customize CNC lathe specifications?

Yes, select suppliers like Jinan Kasen and Taian Best offer customization in material handling, chuck size, control systems (Fanuc, Siemens, GSK), graphic interfaces, and even branded packaging. Technical drawings or CAD files are recommended to initiate modification requests.

Are Chinese CNC lathes CE certified?

Certification varies by manufacturer. While some suppliers declare compliance, buyers must request verifiable CE test reports or third-party inspection certificates. Independent verification through agencies like TÜV or SGS is advised before customs clearance in regulated markets.

Do suppliers provide technical support and training?

Support policies differ. High-end suppliers often include basic setup guides and remote troubleshooting. For complex installations, negotiate on-site commissioning or virtual training sessions during contract finalization. Availability of English-speaking technicians should be confirmed prior to purchase.