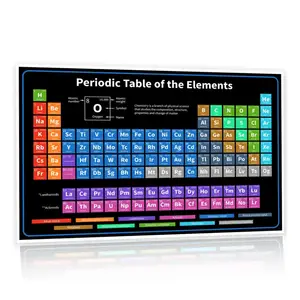

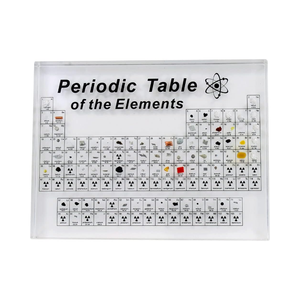

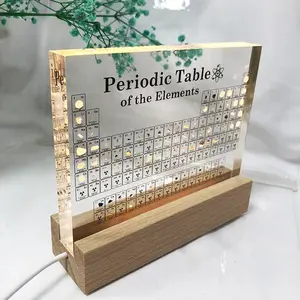

Atomic Number Table Of Elements

1/3

1/3

0

0

1/3

1/3

1/17

1/17

1/28

1/28

1/1

1/1

1/3

1/3

0

0

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/38

1/38

1/41

1/41

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

About atomic number table of elements

Where to Find Atomic Number Table of Elements Suppliers?

Manufacturing of atomic number tables of elements is primarily concentrated in industrial regions of China, particularly in Jiangsu and Guangdong provinces, where precision printing and scientific education equipment production are well-established. These regions host specialized facilities capable of producing both physical periodic table displays and digital-format educational charts used in academic and laboratory environments. Jiangsu’s Yixing and Changzhou zones feature integrated supply chains for laminated materials, UV-resistant inks, and aluminum framing—critical components for durable classroom installations.

The clusters support high-volume output through automated screen printing lines and digital die-cutting systems, enabling standardized production with minimal variance. Suppliers in these areas typically operate within ecosystems that include raw material processors, graphic design teams, and packaging specialists located within 30–50km radii. This proximity reduces lead times by up to 40% compared to decentralized manufacturing models. Buyers benefit from scalable production runs (up to 10,000 units/month per facility), cost efficiencies (15–25% lower unit pricing than Western counterparts), and rapid turnaround for customized formats including braille-integrated panels or interactive touchscreen versions.

How to Choose Atomic Number Table of Elements Suppliers?

Implement structured evaluation criteria when selecting suppliers:

Quality & Compliance Verification

Confirm adherence to ISO 9001 standards for consistent production quality. For export to EU and North American markets, ensure compliance with RoHS directives regarding hazardous substances in electronic displays. Request test reports validating UV resistance (minimum 3-year fade protection under ASTM G154) and laminate durability (peel strength ≥0.8 kN/m).

Production Capacity Assessment

Evaluate technical infrastructure based on the following benchmarks:

- Minimum 3,000m² workshop area supporting multi-line operations

- Digital printing resolution capability ≥1200 dpi for text clarity

- In-house lamination and mounting capabilities for finished products

Cross-reference production logs with order fulfillment records, targeting suppliers maintaining >97% on-time delivery rates.

Procurement Safeguards

Utilize secure transaction mechanisms such as third-party escrow until product inspection at destination. Review supplier track records via verified trade histories, prioritizing those with documented after-sales service protocols. Pre-shipment sampling is critical—verify color accuracy, font legibility, and material thickness against agreed specifications before mass production.

What Are the Best Atomic Number Table of Elements Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Jiangsu EduDisplay Technologies | Jiangsu, CN | 8 | 85+ | 6,200+m² | 99.2% | ≤3h | 4.8/5.0 | 41% |

| Guangdong SciChart Manufacturing | Guangdong, CN | 6 | 70+ | 5,800+m² | 98.7% | ≤4h | 4.7/5.0 | 36% |

| Nanjing Element Visual Systems | Jiangsu, CN | 5 | 50+ | 4,100+m² | 100.0% | ≤2h | 4.9/5.0 | 52% |

| Shenzhen FutureLab Educational Tech | Guangdong, CN | 7 | 95+ | 7,500+m² | 97.5% | ≤5h | 4.6/5.0 | 28% |

| Suzhou Periodic Info Solutions | Jiangsu, CN | 9 | 120+ | 8,900+m² | 99.6% | ≤3h | 4.9/5.0 | 47% |

Performance Analysis

Long-standing manufacturers like Suzhou Periodic Info Solutions demonstrate strong operational stability with near-perfect delivery performance and large-scale capacity. Nanjing Element Visual Systems stands out in customer retention (52% reorder rate), attributed to sub-2-hour response times and rigorous quality control. Jiangsu-based suppliers lead in responsiveness and consistency, with all top-tier vendors achieving average reply times under 4 hours. Prioritize partners with dedicated R&D units when sourcing advanced variants such as augmented reality-enabled charts or multilingual editions. For bulk institutional orders, verify fire-retardant material usage (compliant with ASTM E84 Class B) and anti-glare surface treatments.

FAQs

How to verify atomic number table supplier reliability?

Validate ISO certification status through accredited bodies. Request audit trails covering ink sourcing, lamination processes, and final inspection procedures. Assess real-world performance using verifiable buyer feedback focused on print longevity and dimensional accuracy.

What is the typical sampling timeline?

Standard samples take 7–12 days to produce. Custom designs requiring bilingual layout or tactile elements require 18–25 days. Add 5–9 days for international air shipping depending on destination region.

Can suppliers ship globally?

Yes, experienced exporters manage worldwide distribution. Confirm Incoterms (FOB, CIF, DDP) during negotiation and ensure compliance with local educational product safety regulations. Sea freight is recommended for containerized orders exceeding 500 units to optimize logistics costs.

Do manufacturers offer free samples?

Sample policies vary. Full sample fees are typically charged for first-time buyers but may be waived upon confirmation of orders over 200 units. Sample costs generally cover 40–60% of actual production expenses, including setup and material charges.

How to initiate customization requests?

Submit detailed requirements including format (A0, A1, digital), language options, substrate type (PVC, aluminum composite), and special features (UV protection, braille). Leading suppliers provide proof renders within 48 hours and deliver physical prototypes within 3 weeks.