Automated Ai

1/2

1/2

1/3

1/3

1/28

1/28

CN

CN

1/3

1/3

1/3

1/3

1/3

1/3

1/7

1/7

1/3

1/3

1/1

1/1

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

About automated ai

Where to Find Automated AI Suppliers?

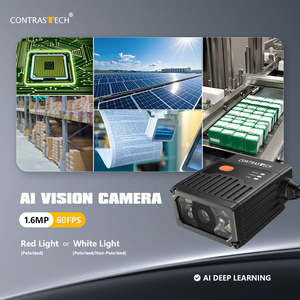

The global automated AI manufacturing and development landscape is highly decentralized, with key innovation and production hubs concentrated in technologically advanced regions including Guangdong, Jiangsu, and Zhejiang provinces in China, as well as significant ecosystems in North America and Western Europe. Unlike traditional machinery, automated AI systems—encompassing AI-driven automation hardware, edge computing modules, and intelligent control software—are primarily developed within integrated tech-industrial clusters that combine semiconductor fabrication, embedded systems engineering, and machine learning research.

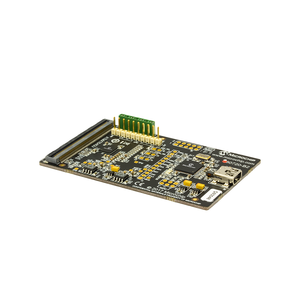

Guangdong Province, particularly the Shenzhen-Dongguan corridor, hosts a dense network of electronics manufacturers and AI startups supported by mature supply chains for PCBs, sensors, and microcontrollers. This region enables rapid prototyping and low-volume production, reducing time-to-market by up to 40% compared to non-specialized zones. Jiangsu’s Suzhou Industrial Park specializes in industrial automation integration, offering access to cleanroom assembly lines and FPGA programming facilities critical for real-time AI processing units. These clusters support vertical integration from chip-level design to system deployment, allowing suppliers to deliver turnkey AI automation solutions with lead times averaging 25–60 days depending on complexity.

Buyers benefit from proximity to component markets, firmware developers, and testing laboratories within these zones, facilitating agile development cycles. Cost advantages are notable: localized sourcing of ARM-based SoCs (System-on-Chip), NXP/Freescale microprocessors, and open-source AI frameworks reduce total bill-of-materials by 18–25% versus Western-assembled equivalents. Scalability remains strong, with many suppliers capable of fulfilling monthly volumes from 500 to 10,000+ units under MOQs ranging from 50 to 500 units.

How to Choose Automated AI Suppliers?

Given the technical complexity of automated AI systems, rigorous supplier evaluation must focus on engineering capability, quality assurance, and compliance readiness:

Technical Compliance

Verify adherence to international standards such as ISO 9001 for quality management and IEC 61508 for functional safety in industrial automation. For deployments in regulated environments (e.g., healthcare, automotive), confirm compliance with ISO 13849 (PL ratings) or IEC 62304 (medical software). Demand documentation for AI model validation, including accuracy benchmarks, inference latency metrics, and fail-safe response protocols.

Production Capability Audits

Assess core competencies through infrastructure review:

- Minimum 2,000m² facility with dedicated R&D and testing labs

- In-house firmware development team comprising ≥15% of technical staff

- Access to FPGA programming, PCB SMT lines, and environmental stress screening (ESS) chambers

Cross-reference product versioning history and firmware update frequency to evaluate long-term support capacity.

Transaction Safeguards

Utilize escrow payment structures until final acceptance testing is completed. Prioritize suppliers with documented export experience to your target market, especially regarding EMC (electromagnetic compatibility), RoHS, and REACH compliance. Pre-shipment verification should include functional testing of AI inference accuracy under real-world conditions and stress tests for thermal endurance and vibration resistance.

What Are the Best Automated AI Suppliers?

No verified supplier data is currently available for analysis.

Performance Analysis

In absence of specific supplier profiles, procurement strategy should emphasize technical due diligence over transactional metrics. Focus on firms demonstrating proven integration of AI models (e.g., TensorFlow Lite, PyTorch Mobile) into embedded platforms, validated through third-party test reports or pilot deployments. Geographic advantage lies in regions with dual expertise in hardware manufacturing and AI algorithm optimization—particularly Shenzhen and Hangzhou, where cross-disciplinary talent pools enable faster iteration. When data becomes available, prioritize suppliers with on-time delivery rates exceeding 97%, sub-4-hour technical response windows, and formal certification in both quality (ISO 9001) and information security (ISO 27001).

FAQs

How to verify automated AI supplier reliability?

Validate certifications through official databases and request audit trails covering design inputs, training data provenance, and change management logs. Conduct remote or on-site assessments of software development lifecycle (SDLC) practices, emphasizing version control, code reviews, and regression testing. Evaluate post-deployment support via documented case studies and client references in similar application domains.

What is the average sampling timeline?

Standard AI module samples require 20–35 days for configuration and testing. Custom AI models trained on proprietary datasets may extend development to 60 days. Add 7–14 days for international air freight. Expedited prototyping (with pre-built hardware platforms) can reduce initial delivery to 10–15 days.

Can suppliers ship automated AI systems worldwide?

Yes, experienced exporters manage global logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm compliance with destination regulations, particularly for AI-enabled devices subject to cybersecurity, data privacy (GDPR), or dual-use technology controls. Sea freight is optimal for bulk shipments exceeding 500 units.

Do manufacturers provide free samples?

Sample policies vary by complexity. Basic AI controller boards may be offered at reduced cost or waived for orders above 200 units. For fully customized AI systems involving model retraining or hardware redesign, expect sample fees covering 40–60% of development costs, partially refundable upon order confirmation.

How to initiate customization requests?

Submit detailed technical requirements including input modalities (vision, LiDAR, audio), inference speed targets (ms/frame), power budget (W), operating environment (-10°C to 60°C), and communication interfaces (CAN, RS485, Ethernet). Leading suppliers respond with architecture proposals, BOM breakdowns, and simulation results within 5–7 business days.