Automated Car Assembly Line

CN

CN

CN

CN

CN

CN

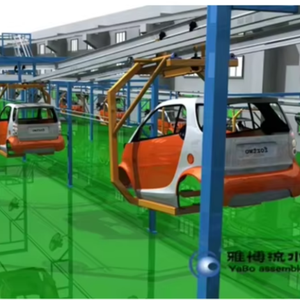

About automated car assembly line

Where to Find Automated Car Assembly Line Suppliers?

China remains the global epicenter for automated car assembly line manufacturing, with key industrial hubs in Henan, Zhejiang, and Jiangsu provinces driving innovation and production scale. Zhengzhou in Henan Province hosts advanced intelligent equipment clusters specializing in full-scale automotive automation systems, leveraging integrated logistics networks for rapid deployment across Asia, Europe, and North America. Nanjing and Suzhou in Jiangsu focus on high-precision customization for electric vehicle (EV) production lines, supported by robust R&D infrastructure and proximity to Tier-1 automotive component suppliers.

Zhejiang’s automation corridor, centered around Hangzhou and Ningbo, emphasizes modular conveyor systems and scalable assembly solutions suitable for both mass production and niche EV manufacturers. These regions benefit from vertically aligned supply chains—spanning robotics integration, control systems, and metal fabrication—enabling lead times as short as 45–60 days for standard configurations. Buyers gain access to flexible manufacturing ecosystems capable of delivering turnkey solutions or modular upgrades, with cost advantages averaging 20–35% over Western counterparts due to localized engineering and production resources.

How to Choose Automated Car Assembly Line Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Integration

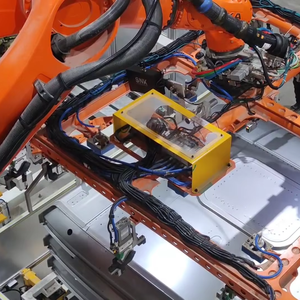

Verify adherence to international quality standards such as ISO 9001 for quality management and CE marking for electrical and mechanical safety compliance. For export-focused buyers, confirm compatibility with IEC 60204-1 (safety of machinery) and PLC control systems from recognized vendors (e.g., Siemens, Allen-Bradley). Request documentation on robotic integration (e.g., ABB, KUKA), sensor networks, and SCADA-based monitoring systems used in the assembly line design.

Production Capability Assessment

Evaluate core manufacturing competencies through the following criteria:

- Minimum factory area exceeding 3,000m² to support large-scale system integration

- In-house engineering teams dedicated to automation design and simulation (preferably >10% of total staff)

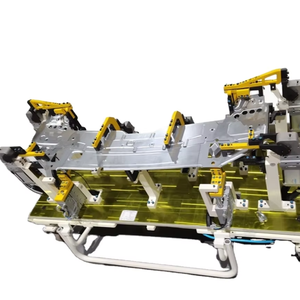

- Proven experience in turnkey automotive assembly projects, including body-in-white (BIW), powertrain, and final assembly zones

Cross-reference project portfolios with on-time delivery performance (target ≥95%) and response time benchmarks (≤8 hours preferred).

Customization & Quality Assurance

Confirm capability for layout optimization, cycle time analysis, and material flow simulation using tools like Tecnomatix or Visual Components. Demand evidence of pre-shipment testing protocols, including dry runs and fault diagnostics. Prioritize suppliers offering video audits or virtual factory walkthroughs to validate process controls and equipment build quality.

Transaction Safeguards

Utilize secure payment structures such as letter of credit (L/C) or escrow services tied to milestone inspections. Review after-sales support terms, including commissioning assistance, operator training, and spare parts availability. Analyze historical reorder rates and customer retention metrics where available—suppliers with repeat business indicate consistent service delivery.

What Are the Best Automated Car Assembly Line Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Henan, CN | Assembly Line, Welding Equipment, Metal Processing Line | 100% | ≤8h | Not disclosed | $32,750–158,000 | 1 set |

| Nanjing Energy Intelligent Co., Ltd. | Jiangsu, CN | Safety Driving Systems, Metal Product Processing Line | 100% | ≤5h | Not disclosed | $300,000 | 1 set |

| Zhejiang Jianggong Automation Equipment Co., Ltd. | Zhejiang, CN | EV Conveyor Lines, Assembly Line Components | 100% | ≤18h | <15% | $1,000–$100,000 | 1 unit/meter |

| Schnoka (Suzhou) Intelligent Equipment Co., Ltd. | Jiangsu, CN | Automotive Automation Solutions | 100% | ≤11h | Not disclosed | $700,000–1,500,000 | 1 set |

| Guangdong Huazhe Intelligent Manufacturing Co., Ltd. | Guangdong, CN | Coating Lines, Body Assembly Systems | Not disclosed | ≤2h | <15% | $1,000–$15,000 | 1 set/piece |

Performance Analysis

Zhengzhou Duoyuan and Schnoka Suzhou demonstrate strong project execution with 100% on-time delivery and comprehensive turnkey offerings, positioning them as ideal partners for mid-to-large scale automotive plants. Nanjing Energy targets premium EV producers with fully customized $300K+ lines focused on energy efficiency and smart monitoring integration. Schnoka stands out for high-complexity installations, offering multi-million-dollar automation packages suited for OEM-level production environments.

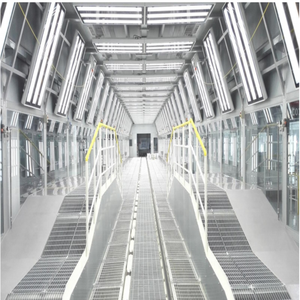

Zhejiang Jianggou provides cost-effective modular components priced per meter or unit, making it suitable for partial line upgrades or startups with limited capital. Guangdong Huazhe excels in sub-system automation—particularly painting and coating lines—with ultra-fast response times (≤2h), though its lower reorder rate suggests room for improvement in long-term client retention. Buyers seeking full plant solutions should prioritize suppliers with documented experience in MES integration, lean manufacturing layouts, and ergonomic workstation design.

FAQs

How to verify automated car assembly line supplier reliability?

Validate certifications (ISO 9001, CE) through official registries and request third-party audit reports if available. Conduct virtual or on-site facility inspections to assess welding precision, control panel construction, and test rig operations. Analyze customer references focusing on system uptime, defect rates, and post-installation support responsiveness.

What is the typical lead time for custom assembly lines?

Standard configurations require 45–60 days from order confirmation. Fully customized turnkey systems, especially those integrating robotics and vision inspection, may take 90–150 days depending on complexity and component sourcing. Allow additional time for shipping: 20–30 days via sea freight to most global ports.

Can suppliers provide assembly line design and simulation?

Yes, leading suppliers offer digital twin modeling, line balancing analysis, and 3D layout simulations using CAD and PLM software. Reputable vendors deliver process validation reports and throughput projections before fabrication begins.

Do manufacturers support overseas installation and training?

Most suppliers include basic commissioning support and remote troubleshooting. For on-site services, clarify travel costs, technician availability, and training duration upfront. Some offer extended warranties or service contracts covering first-year maintenance.

What are common customization options?

Key configurable parameters include conveyor speed, station count, payload capacity, robot type (articulated/SCARA), control interface language, and integration with existing ERP/MES platforms. Suppliers typically allow modifications to color coding, safety guarding, and labeling per regional regulations.