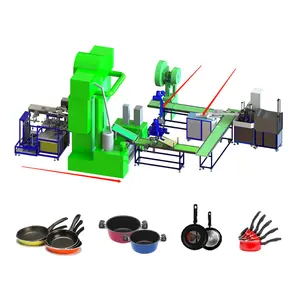

Automated Production Equipment Examples

CN

CN

Top sponsor listing

Top sponsor listing

About automated production equipment examples

Where to Find Automated Production Equipment Suppliers?

China remains the global epicenter for automated production equipment manufacturing, with key supplier clusters concentrated in Shandong, Zhejiang, Henan, and Guangdong provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, robotics integration, and large-scale fabrication capabilities. Shandong and Zhejiang stand out for their specialization in turnkey assembly lines and robotic automation systems, while Dongguan and Changsha serve as innovation hubs for electronics-focused automation machinery.

The clustering effect enables suppliers to offer scalable production capacity, reduced component sourcing lead times, and rapid prototyping cycles. Facilities commonly operate across 5,000–24,000+ m² campuses equipped with CNC machining centers, welding bays, and PLC testing labs. This infrastructure supports efficient fulfillment of both standard and custom-engineered solutions, with typical delivery windows ranging from 30 to 60 days depending on complexity. Buyers benefit from localized supply chains that reduce costs by 20–35% compared to Western equivalents, particularly for high-volume or customized automated systems.

How to Choose Automated Production Equipment Suppliers?

Selecting reliable partners requires a structured evaluation framework focused on technical capability, operational performance, and transactional safeguards.

Technical & Engineering Capabilities

Prioritize suppliers demonstrating proven expertise in control systems (PLC, HMI, SCADA), robotics integration (collaborative, articulated, or SCARA robots), and process-specific automation (assembly, packaging, welding). Verify access to in-house R&D teams capable of delivering custom configurations based on client workflows. For regulated industries, ensure compliance with relevant standards such as CE, ISO 9001, and RoHS. Request detailed documentation on motor specifications, sensor types, safety interlocks, and software interfaces.

Production Infrastructure Assessment

Evaluate physical and operational benchmarks:

- Minimum factory area of 5,000m² to support full-line assembly

- In-house capabilities including CNC machining, sheet metal fabrication, electrical panel assembly, and final system integration

- Dedicated quality control stations with functional testing protocols

Cross-reference facility scale with on-time delivery rates (target ≥98%) and reorder rates (indicative of customer satisfaction).

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services tied to milestone inspections. Conduct virtual or on-site audits to verify automation programming practices, wiring standards, and mechanical tolerances. Require sample validation under real operating conditions—particularly for customized conveyor layouts, pick-and-place sequences, or vision-guided systems—before approving full production runs.

What Are the Best Automated Production Equipment Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Typical MOQ | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shandong Chenxuan Robot Technology Co., Ltd. | Shandong, CN | Articulated Robots, Collaborative Robots, Welding Equipment, Press Brakes | 100.0% | ≤2h | - | Color, material, size, logo, packaging, label, graphics | 1 set | $18,000–$230,000 |

| Zhejiang Yabo Automation Equipment Co., Ltd. | Zhejiang, CN | Bus Assembly Lines, Washing Machine Lines, Transformer Lines, Vehicle Production Systems | 100.0% | ≤4h | - | Full line customization available | 1 set | $50,000–$500,000 |

| Luohe Ruihao Intelligent Equipment Co., Ltd. | Henan, CN | Dry Mortar Lines, Mixing Equipment, Packaging & Wrapping Machines | 100.0% | ≤2h | 33% | Limited customization per model | 1 piece | $14,900–$20,000 |

| Dongguan Yicheng Automation Equipment Co., Ltd. | Guangdong, CN | Switch/Socket Machinery, Valve Assembly, Gearbox Lines, PLC-Controlled Systems | 100.0% | ≤6h | - | Design-to-spec supported | 1 set | $30,000–$65,000 |

| Hunan Junjiesheng Automation Equipment Co., Ltd. | Hunan, CN | Speaker Production Lines, Magnetic Circuit Machines, Gluing Systems | 100.0% | ≤2h | - | High customization for electronics lines | 1 set | $18,000–$230,000 |

Performance Analysis

All five suppliers maintain perfect on-time delivery records, indicating strong project management and logistics coordination. Shandong Chenxuan and Hunan Junjiesheng lead in responsiveness (≤2h average), making them suitable for time-sensitive procurement cycles. Zhejiang Yabo specializes in high-value industrial assembly systems exceeding $500,000, reflecting its position in heavy automation sectors. In contrast, Luohe Ruihao offers lower-cost semi-automated mortar and mixing solutions ideal for construction materials producers seeking entry-level automation. Dongguan Yicheng provides mid-range pricing with strong focus on electronics and component assembly applications, backed by PLC-driven flexibility.

FAQs

How to verify automated production equipment supplier reliability?

Confirm certifications such as ISO 9001, CE, and electrical safety marks. Request evidence of past installations through case studies or video walkthroughs. Analyze transaction history focusing on response consistency, dispute resolution, and post-delivery support. Third-party inspection reports can validate build quality prior to shipment.

What is the typical lead time for automated production lines?

Standard systems require 30–45 days for manufacturing and testing. Customized or large-scale lines (e.g., automotive or appliance assembly) may take 60–90 days. Rush orders with expedited fees can reduce timelines by 10–15 days, subject to component availability.

Do suppliers support OEM branding and design modifications?

Yes, most suppliers listed offer OEM labeling, color schemes, and interface localization. Full mechanical redesigns require engineering collaboration and may incur NRE (non-recurring engineering) charges. Quotes should specify which elements are modifiable without cost penalties.

Can automated equipment be shipped internationally?

All major suppliers export globally via FOB or CIF terms. Sea freight is standard for complete lines due to size and weight. Pre-shipment documentation includes packing lists, electrical schematics, and compliance certificates necessary for customs clearance in destination markets.

Is sample testing available before bulk ordering?

Functional prototypes or single-unit samples are available upon request, typically at 30–50% of unit cost. Testing periods range from 7–14 days, during which buyers can assess cycle time accuracy, fault recovery, and human-machine interface usability. Sample fees may be credited toward first production orders.