Automated Manufacturing Systems Examples

CN

CN

CN

CN

1/2

1/2

CN

CN

1/10

1/10

1/20

1/20

CN

CN

1/21

1/21

1/30

1/30

About automated manufacturing systems examples

Where to Find Automated Manufacturing Systems Suppliers?

China remains the global epicenter for automated manufacturing systems production, with concentrated industrial hubs in Shanghai, Zhengzhou, and Shenzhen offering specialized expertise. These regions host vertically integrated supply chains that support rapid prototyping, scalable production, and advanced automation integration. Shanghai excels in intelligent logistics and warehouse automation, leveraging proximity to port infrastructure for efficient export distribution. Zhengzhou has emerged as a center for automotive and battery assembly line systems, supported by regional investments in new energy vehicle (NEV) manufacturing. Shenzhen’s strength lies in electronics-focused automation, particularly SMT and component assembly machinery, benefiting from its dense ecosystem of electronic component suppliers and R&D talent.

Suppliers in these clusters operate within mature industrial networks where design, machining, control system integration, and testing occur under one roof or within 50km radius ecosystems. This integration enables lead times averaging 45–60 days for standard configurations, with cost advantages of 20–35% over Western manufacturers due to lower labor costs and localized sourcing of structural steel, motors, and control hardware. Buyers gain access to both standardized turnkey lines and highly customizable systems tailored to specific throughput, footprint, or Industry 4.0 compliance requirements.

How to Choose Automated Manufacturing Systems Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Integration Capability

Verify adherence to international standards such as CE, ISO 9001, and where applicable, UL or RoHS for electronic components. For smart factory deployments, confirm compatibility with MES (Manufacturing Execution Systems), SCADA, and IIoT protocols. Demand detailed documentation on PLC programming (Siemens, Allen-Bradley, Mitsubishi), HMI interfaces, and error logging functionality. Suppliers should provide simulation models or 3D layouts prior to fabrication.

Production Capacity & Engineering Resources

Assess core capabilities through objective metrics:

- Minimum facility size of 3,000m² to ensure dedicated assembly zones

- In-house engineering teams capable of non-standard design (e.g., custom conveyor integration, vision-guided robotics)

- On-site CNC machining, welding, and electrical panel fabrication

Cross-reference declared capabilities with response time (target ≤5 hours) and reorder rate data to validate customer satisfaction and service responsiveness.

Transaction Security & Validation Protocols

Utilize secure payment mechanisms such as escrow services until final inspection clearance. Prioritize suppliers with verifiable on-time delivery performance (≥97%) and transparent revenue reporting. Conduct pre-shipment audits via video walkthroughs or third-party inspection agencies. Request test runs recorded under load conditions to verify cycle time accuracy and fault recovery procedures.

What Are the Best Automated Manufacturing Systems Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Key Product Examples |

|---|---|---|---|---|---|---|---|

| Woolley Automatic Machinery Ltd. (shanghai) | Shanghai, CN | Offset Printers, Packaging Lines, Injection Molding Machines | US $1,500,000+ | 100% | ≤5h | 33% | Laminated Tube Manufacturing Equipment, Automatic Cosmetic Tube Making Machine |

| Zhengzhou Duoyuan Intelligent Equipment Co., Ltd. | Zhengzhou, CN | Assembly Line, Welding Equipment, Automotive Production Lines | Not Disclosed | 100% | ≤8h | - | Car Manufacturing Cell Assembly Line, Lithium Battery Production Line |

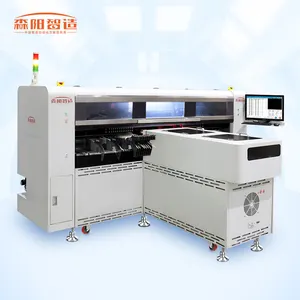

| Shenzhen Sun Young Intelligent Manufacturing Equipment Co., Limited | Shenzhen, CN | SMT Machinery, Electronics Production Lines, LED Strip Machines | US $500+ | 100% | ≤3h | - | Fully Automatic SMT Production Machinery, Electronic Component Making Machines |

| Shanghai Janwo Machinery Co., Ltd. | Shanghai, CN | AGV Robots, Intelligent Warehousing, Packaging Lines | Not Disclosed | 100% | ≤2h | - | Intelligent Logistics System, 3D Warehouse Storage Shelves, Stacker Cranes |

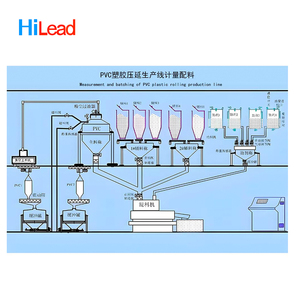

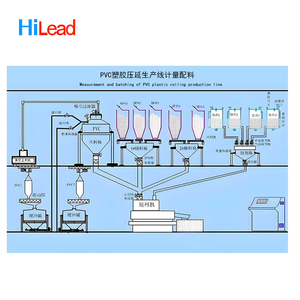

| Benlong Automation Technology Co., Ltd. | Not Specified, CN | MES Systems, Circular Conveyors, MCB & Meter Assembly Lines | Not Disclosed | 100% | ≤3h | - | MCB Automated Production Line, Electric Energy Meter Assembly System |

Performance Analysis

Woolley Automatic Machinery stands out with high reorder rates (33%) and substantial online revenue, indicating strong market acceptance in packaging automation. Zhengzhou Duoyuan offers large-scale solutions for automotive and energy storage sectors, including multi-million dollar production lines. Shenzhen Sun Young specializes in precision electronics automation with fast response cycles, ideal for buyers requiring agile engineering support. Shanghai Janwo focuses on material handling and smart warehouse integration, providing modular AGV-based systems. Benlong Automation delivers high-value MES-integrated lines, particularly for electrical equipment manufacturing, with pricing reaching up to $345,000 per system. All five suppliers demonstrate perfect on-time delivery records, suggesting robust internal scheduling and quality control processes.

FAQs

How to verify automated manufacturing system supplier reliability?

Cross-check certifications (ISO 9001, CE) with issuing bodies and request copies of test reports for safety circuits, motor drives, and emergency stop functions. Analyze supplier-provided project references, especially installations in your target region. Evaluate responsiveness and technical depth during initial inquiries—prompt, detailed replies indicate organized internal workflows.

What is the typical lead time for custom automated systems?

Standard configurations ship in 45–60 days after order confirmation. Fully customized systems with integrated robotics or proprietary software require 90–120 days, including design review, prototyping, and FAT (Factory Acceptance Testing). Expedited builds may reduce timelines by 15–20% at additional cost.

Do suppliers offer installation and commissioning support?

Most suppliers provide remote commissioning assistance and technical manuals. On-site support is typically available at extra cost, ranging from $150–$300/hour plus travel. Clarify warranty terms—standard coverage is 12 months on mechanical parts and 6 months on electrical components.

Can automated systems be scaled for future expansion?

Yes, leading suppliers design modular architectures using standardized conveyors, I/O modules, and communication protocols (e.g., Profinet, EtherCAT). Confirm scalability during design phase by requesting layout adaptability studies and upgrade path documentation.

What are common MOQ and pricing structures?

MOQ is typically 1 set or unit, even for high-cost systems. Pricing varies widely: tube-making machines start around $10,000, while full battery or MCB assembly lines exceed $200,000. Negotiate bundled deals for multiple units or complementary subsystems (e.g., feeding + assembly + testing).