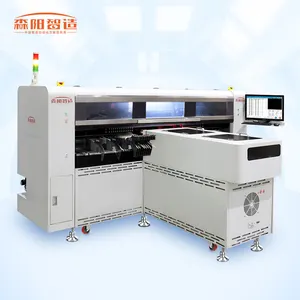

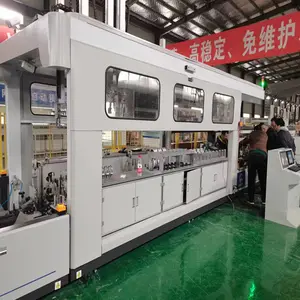

Types Of Automated Manufacturing Systems

CN

CN

CN

CN

About types of automated manufacturing systems

Where to Find Automated Manufacturing Systems Suppliers?

China remains the global epicenter for automated manufacturing systems production, with key supplier clusters concentrated in Shanghai, Shenzhen, and Wenzhou. These regions host vertically integrated industrial ecosystems that combine precision engineering, automation R&D, and scalable fabrication. Shanghai and Shenzhen lead in high-complexity assembly and Industry 4.0-integrated production lines, supported by robust electronics and robotics supply chains. Wenzhou specializes in liquid and semi-solid packaging automation, leveraging decades of experience in food, pharmaceutical, and cosmetic processing equipment.

The clustering enables streamlined component sourcing, rapid prototyping, and reduced logistics overhead. Suppliers in these zones typically operate within 50km of critical subsystem providers—such as servo motors, PLCs, and pneumatic systems—reducing lead times by up to 25%. Buyers benefit from established infrastructure offering standard delivery windows of 30–60 days, depending on system complexity. Localized manufacturing also translates to 20–35% lower unit costs compared to equivalent systems produced in North America or Europe, particularly for turnkey solutions requiring multi-stage integration.

How to Choose Automated Manufacturing Systems Suppliers?

Selecting a reliable supplier requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm compatibility with Industry 4.0 standards where applicable, including SCADA integration, IoT-enabled monitoring, and programmable logic controller (PLC) architecture. For regulated industries (e.g., food, cosmetics, pharmaceuticals), ensure compliance with ISO 22000, GMP, or FDA guidelines. CE marking is essential for EU market access, while UL/CSA certification may be required for North American deployments. Request validation documentation for critical subsystems such as filling accuracy, sealing integrity, and motion control repeatability.

Production Capacity Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² for full-line system integration

- In-house engineering team capable of custom layout design and simulation

- Proven track record in turnkey project execution (design, installation, commissioning)

- On-site testing facilities for dry runs and performance benchmarking

Cross-reference online revenue indicators and reorder rates to assess scalability and customer retention. Prioritize suppliers with ≤8-hour response times and documented after-sales support frameworks.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align financial release with milestone verification. Conduct pre-shipment inspections either independently or through third-party agencies like SGS or Bureau Veritas. Require sample testing under real-world conditions—especially for viscosity-sensitive applications like food paste or liquid soap—to validate throughput, fill consistency, and downtime frequency before full deployment.

What Are the Best Automated Manufacturing Systems Suppliers?

| Company Name | Location | Main Products | System Price Range (USD) | Min. Order Quantity | On-Time Delivery | Avg. Response Time | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Woolley Automatic Machinery Ltd. (shanghai) | Shanghai, CN | Tube Manufacturing Equipment, Laminating Machines, Filling Systems | $9,999–10,000 | 1 set | 100% | ≤4h | 33% | US $1,500,000+ |

| Shenzhen Tianluo Automation Equipment Co., Ltd. | Shenzhen, CN | Assembly Lines, Electronic Processing, Mask Making Machines | $20,000–50,000 | 1 set | 100% | ≤5h | 100% | US $2,000+ |

| Shenzhen Qihang Electronics Co., Ltd. | Shenzhen, CN | Coating Systems, Electrophoresis Equipment, Turnkey Production Lines | $34,500–36,000 | 1 piece | 100% | ≤2h | <15% | US $340,000+ |

| Wenzhou Ace Machinery Co., Ltd. | Wenzhou, CN | Mixing Equipment, Dairy & Beverage Processing, Fermentation Systems | $509–20,000 | 1 set | 100% | ≤8h | 18% | US $70,000+ |

| Xiamen Xinaoge Automation Equipment Co., Ltd. | Xiamen, CN | Shoe Production Lines, Injection Molding, Rubber Machinery | $600,000 | 1 set | 100% | ≤2h | - | - |

Performance Analysis

Suppliers vary significantly in specialization and pricing tiers. Wenzhou Ace Machinery offers entry-level automation for food and liquid processing at competitive prices ($509–$20,000), making it suitable for SMEs or pilot deployments. In contrast, Xiamen Xinaoge targets high-volume footwear and rubber goods manufacturers with fully automated production lines priced at $600,000 per set, indicating enterprise-grade integration and durability. Shenzhen Tianluo stands out with a 100% reorder rate, reflecting strong customer satisfaction in electronic assembly and customizable valve automation. Despite limited public revenue data, its consistent delivery and responsive communication suggest operational maturity. Shenzhen Qihang and Woolley Automatic Machinery provide mid-range coating and tube-filling systems with advanced customization options—including vacuum chambers, infrared heating, and electrostatic spray controls—ideal for specialized surface treatment applications.

FAQs

How to verify automated manufacturing system supplier reliability?

Validate certifications (ISO 9001, CE) through issuing bodies and request audit trails covering material sourcing, quality control checkpoints, and final system testing. Analyze buyer feedback focusing on post-installation support, uptime performance, and software interface stability. Video facility tours can confirm in-house engineering capacity and assembly line organization.

What is the typical lead time for automated manufacturing systems?

Standard configurations ship within 30–45 days after order confirmation. Customized or turnkey projects require 60–90 days, depending on design complexity and component availability. High-end systems involving robotic integration or Industry 4.0 connectivity may extend to 120 days.

Do suppliers offer customization for production line integration?

Yes, most suppliers support layout adaptation, speed adjustment, and interface customization (e.g., HMI languages, PLC protocols). Shenzhen-based firms often provide CAD modeling and simulation outputs within 72 hours of receiving technical specifications. Minimum order requirements typically remain at one set, even for bespoke builds.

Can automated manufacturing systems be shipped globally?

All listed suppliers export internationally. Confirm Incoterms (FOB, CIF) during negotiation and verify compliance with destination-country electrical standards (voltage, frequency) and machinery safety regulations. Sea freight is standard for full systems due to size and weight; air shipping is feasible only for modular components.

Is sample testing available before full procurement?

Sample runs are possible for certain product types (e.g., tube filling, liquid dispensing). Suppliers may charge 30–50% of unit cost to cover material and labor. For high-value systems, virtual commissioning via live video testing is commonly offered as an alternative to physical sampling.