Components Of Automated Manufacturing System

CN

CN

CN

CN

CN

CN

CN

CN

About components of automated manufacturing system

Where to Find Suppliers for Components of Automated Manufacturing Systems?

China remains the central hub for manufacturing components of automated manufacturing systems, with key supplier clusters concentrated in Shenzhen and Dongguan within Guangdong Province. These regions host vertically integrated ecosystems combining precision engineering, electronics production, and industrial automation expertise. Shenzhen’s advanced supply chain infrastructure enables rapid prototyping and customization, while Dongguan offers cost-efficient mass production supported by mature metalworking and coating industries.

The proximity of component suppliers, R&D centers, and logistics networks within a 50km radius reduces lead times and enhances coordination. Buyers benefit from scalable production capacity, localized sourcing of raw materials such as aluminum alloys and industrial-grade polymers, and access to specialized processing techniques including CNC machining, surface coating, and robotic integration. Typical lead times range from 30–60 days depending on complexity, with 20–30% lower production costs compared to equivalent systems sourced from North America or Europe.

How to Choose Suppliers for Components of Automated Manufacturing Systems?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers support core functionalities such as PLC control, servo-driven motion systems, and CCD vision alignment. For high-precision applications (e.g., SMT assembly or micro-dispensing), validate machine accuracy specifications—look for repeatability within ±0.01mm. Request documentation on motor types (e.g., 5-axis servo systems), software interfaces, and compatibility with existing factory automation protocols (e.g., Modbus, EtherCAT).

Production Infrastructure Assessment

Evaluate supplier facilities based on the following criteria:

- Minimum factory area exceeding 2,000m² for stable batch production

- In-house engineering teams capable of custom design and integration

- On-site testing capabilities for performance validation under simulated operating conditions

Cross-reference delivery performance (target: 100% on-time fulfillment) and response time (ideally ≤3 hours) to assess operational reliability.

Quality & Transaction Assurance

Prioritize suppliers demonstrating adherence to international quality standards. While formal ISO 9001 certification is not universally listed, consistent on-time delivery records and verifiable online revenue indicate process maturity. Utilize secure payment mechanisms and require functional testing prior to shipment. For customized systems, request video demonstrations or facility walkthroughs to verify production readiness.

What Are the Leading Suppliers of Components of Automated Manufacturing Systems?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

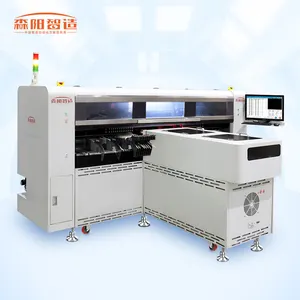

| Shenzhen Sun Young Intelligent Manufacturing Equipment Co., Limited | Shenzhen, CN | Electronics Production Machinery, SMT Equipment, Cable Manufacturing Equipment | $5,000–45,800 | 1 piece/set | 100.0% | ≤3h | US $500+ | - |

| Shenzhen Second Intelligent Equipment Co., Ltd. | Shenzhen, CN | Desktop SMT Machines, 3-/5-Axis Dispensing Systems, Custom Automation | $3,000–12,900 | 1 piece | 100.0% | ≤2h | US $490,000+ | 50% |

| Dongguan Zhuoding Mechanical Equipment Technology Co., Ltd. | Dongguan, CN | Automated Coating Lines, Paint Spraying Systems, Air Supply Units | $3,800–6,500 | 1 set | 100.0% | ≤3h | - | - |

| Shenzhen Zeyu Intelligent Industrial Science Technology Co., Ltd. | Shenzhen, CN | Assembly Machines, Industrial Robots, Custom Automation Solutions | $900–220,000 | 1 set | 100.0% | ≤2h | US $2,000+ | - |

| Dongguan Yicheng Automation Equipment Co., Ltd. | Dongguan, CN | Automated Assembly Lines, PLC-Controlled Systems, Catheter & MCB Equipment | $30,000–80,000 | 1 set | 100.0% | ≤7h | - | - |

Performance Analysis

Shenzhen-based suppliers demonstrate strong responsiveness and specialization in electronics automation, with Shenzhen Second Intelligent Equipment achieving a 50% reorder rate—indicative of customer satisfaction in niche desktop automation. Dongguan Yicheng focuses on high-value industrial systems, offering turnkey solutions for medical device and electrical component assembly at premium price points. Despite limited public revenue data, all listed suppliers maintain perfect on-time delivery records, suggesting disciplined production planning. Buyers seeking customization should prioritize companies advertising design flexibility and direct manufacturing capabilities, particularly those supporting color, material, and labeling modifications.

FAQs

How to verify the reliability of automated system component suppliers?

Assess consistency in delivery performance and communication speed. Request technical drawings, control system details, and sample videos of running equipment. Validate claims through transaction history and customer feedback where available.

What is the typical minimum order quantity (MOQ)?

Most suppliers offer MOQs of 1 unit or set, facilitating low-volume procurement for testing or small-scale deployment. Bulk pricing may apply for orders exceeding five units.

Are customization options available for automated manufacturing components?

Yes, several suppliers support tailored configurations including size adjustments, material selection, branding, and software interface modifications. Lead times for custom builds typically extend by 15–30 days.

Do suppliers provide technical support after delivery?

Support varies by provider. Some offer remote troubleshooting and operational guidance, particularly those with established export experience. Clarify post-sale service terms—including training and spare parts availability—before finalizing contracts.

What are the common packaging and shipping methods?

Machines are generally secured in wooden crates suitable for sea or air freight. Suppliers often coordinate FOB shipping, though buyers can designate logistics partners. Allow 7–14 days for international transit depending on destination and mode.