Types Of Manufacturing Systems In Production And Operations Management

CN

CN

CN

CN

About types of manufacturing systems in production and operations management

Where to Source Manufacturing Systems for Production and Operations Management?

The global supply base for manufacturing systems in production and operations management is concentrated among specialized technology firms offering integrated software and hardware solutions. Key suppliers are primarily located in China, with operational hubs in Guangdong, Shanghai, and Fujian provinces. These regions host vertically integrated ecosystems combining industrial automation expertise, software development capabilities, and precision engineering infrastructure.

Industrial clusters in Guangdong and Shanghai provide strategic advantages through proximity to semiconductor, PCB, and robotics supply chains, reducing component procurement lead times by 20–30%. Suppliers benefit from established logistics networks enabling efficient export via Shenzhen, Guangzhou, and Shanghai ports. The integration of smart manufacturing R&D centers within these zones supports rapid prototyping and customization cycles, typically ranging from 15 to 45 days depending on system complexity.

Buyers access a mature supplier landscape featuring companies with dedicated teams in MES (Manufacturing Execution Systems), warehouse management software, automated assembly lines, and real-time inventory control platforms. These suppliers cater to discrete, process, and hybrid manufacturing environments across electronics, automotive, pharmaceuticals, and consumer goods sectors.

How to Evaluate Suppliers of Manufacturing Systems?

Selecting reliable partners requires rigorous assessment across technical, operational, and transactional dimensions:

System Architecture & Technical Compliance

Verify that proposed systems align with ISA-95 or ANSI/ISA-88 standards for enterprise-control system integration. For international deployment, ensure compatibility with local data protection regulations (e.g., GDPR, CCPA) and cybersecurity protocols such as IEC 62443. Demand documented validation of system uptime (target: ≥99.5%) and failover redundancy mechanisms.

Production and Customization Capability

Assess supplier capacity through the following benchmarks:

- Proven experience in deploying end-to-end systems (MES, WMS, SCADA) across multiple production environments

- In-house software development teams with version-controlled code repositories and agile deployment pipelines

- Integration capability with PLCs, HMIs, RFID systems, and IIoT sensors from major vendors (Siemens, Rockwell, Mitsubishi)

- Support for modular expansion and API-based connectivity to ERP platforms (SAP, Oracle, Microsoft Dynamics)

Cross-reference project portfolios with on-time delivery performance (target: 100%) and average response time (preferred: ≤4 hours) to gauge operational responsiveness.

Quality Assurance and Transaction Security

Prioritize suppliers adhering to ISO 9001 quality management and ISO/IEC 27001 for information security. Require third-party testing reports for system stability under peak load conditions. Utilize secure payment frameworks with milestone-based releases tied to commissioning and user acceptance testing (UAT). Conduct remote or on-site audits to validate server infrastructure, data encryption practices, and disaster recovery plans before deployment.

What Are the Leading Manufacturing System Suppliers?

| Company Name | Specialization | Product Range | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization |

|---|---|---|---|---|---|---|---|---|

| Benlong Automation Technology Co., Ltd. | MES, Intelligent Production Systems | Intelligent MES, Warehouse Management, Process Optimization | $11,500–50,000 | 1 set | 100.0% | ≤4h | - | Limited |

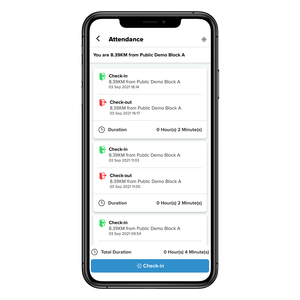

| Shanghai Jigong Intelligent Information Technology Co., Ltd. | Custom MES & Warehouse Software | Customizable MES, Efficiency Software, Production Control | $1,000 (fixed) | 1 piece | 100.0% | ≤11h | - | High |

| Yalong Intelligent Equipment Group Co., Ltd. | Educational & Industrial Smart Manufacturing Lines | Flexible Manufacturing Trainers, Automated Production Systems, Robotics Integration | $100,000–1,000,000 | 1 set | 100.0% | ≤14h | - | Moderate |

| INTELLISENSE TECHNOLOGY | Real-Time Inventory Control PCBs | PCB Platforms for Raw Material & Inventory Management | $99–499 | 99 pieces | - | ≤4h | - | Low |

| Guangdong Gosunm Intelligent Industry Co., Ltd. | Custom Assembly & Sorting Systems | Intelligent DWS Sorting, Automatic Assembly Lines, Logistics Equipment | $4,580–9,980 | 1 set | 100.0% | ≤2h | 60% | High |

Performance Analysis

Benlong Automation and Yalong offer high-capacity integrated systems suited for large-scale industrial deployments, with Yalong focusing on training and pilot-line applications. Shanghai Jigong stands out for low-cost, fully customizable software modules ideal for SMEs seeking scalable MES functionality. INTELLISENSE TECHNOLOGY provides entry-level hardware components for inventory tracking at competitive unit prices, suitable for component-level integration. Guangdong Gosunm demonstrates strong buyer retention (60% reorder rate) supported by rapid response times and extensive customization options in material handling and sorting configurations. Suppliers with sub-4-hour response windows exhibit higher engagement levels, critical for timely troubleshooting during implementation phases.

FAQs

What certifications should manufacturing system suppliers have?

Essential certifications include ISO 9001 for quality management and ISO/IEC 27001 for data security. For EU markets, compliance with GDPR and CE marking (for embedded hardware) is required. Suppliers integrating industrial control systems should adhere to IEC 62443 cybersecurity standards.

What is the typical lead time for manufacturing system deployment?

Standard software-based systems require 15–30 days for configuration and testing. Fully integrated hardware-software solutions (e.g., automated assembly lines) take 45–90 days, including factory acceptance testing (FAT). Custom developments may extend timelines by an additional 30 days.

Can suppliers integrate manufacturing systems with existing ERP platforms?

Yes, most suppliers support integration with SAP, Oracle, and Microsoft Dynamics via REST APIs, OPC UA, or middleware platforms. Confirm pre-built connectors and conduct proof-of-concept testing to validate data synchronization accuracy and latency.

Do suppliers offer post-deployment support?

Reputable providers deliver structured support packages including remote monitoring, periodic updates, and SLA-backed incident resolution (typically 24/7 for Tier-1 systems). Minimum service agreements often cover 12 months of maintenance and bug fixes.

How to assess scalability of a manufacturing system?

Evaluate modularity, concurrent user licensing limits, and database throughput metrics. Request case studies demonstrating successful scaling across multiple production lines or sites. Stress-test system performance under simulated peak loads before final approval.