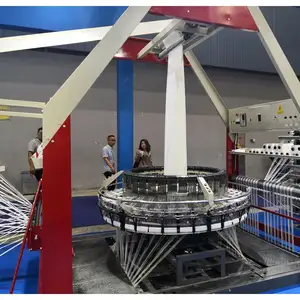

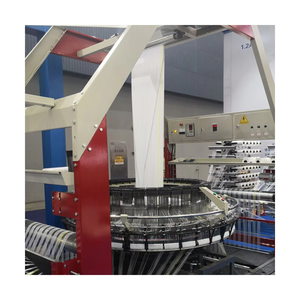

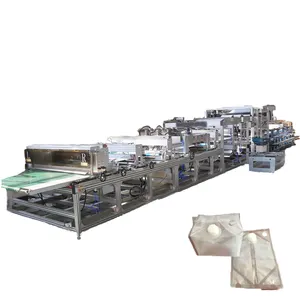

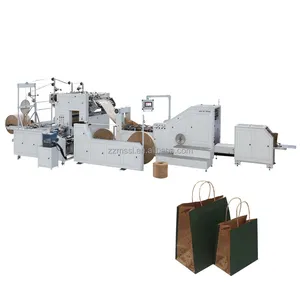

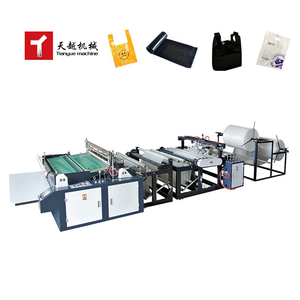

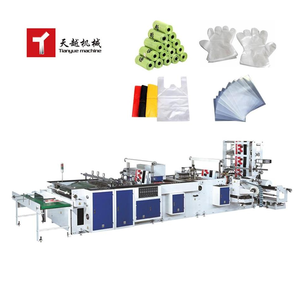

Automatic Bag Making Machine

Top sponsor listing

Top sponsor listing

About automatic bag making machine

Where to Find Automatic Bag Making Machine Suppliers?

China remains the global epicenter for automatic bag making machine manufacturing, with key industrial clusters concentrated in Zhejiang, Guangdong, and Shandong provinces. These regions host vertically integrated supply chains that support rapid prototyping and high-volume production of machinery for plastic, non-woven, woven, and paper-based bags. Zhejiang and Ruian are particularly renowned for precision engineering in packaging automation, while Shenzhen and Jinan have emerged as hubs for cost-effective, multi-functional systems integrating lamination, printing, and sealing processes.

The concentration of component suppliers, CNC workshops, and assembly facilities within 50km radii enables streamlined production cycles and faster order fulfillment. Buyers benefit from localized access to servo motors, control panels, heating elements, and film handling systems—reducing lead times by up to 30% compared to offshore alternatives. Average delivery windows range from 20–40 days for standard configurations, with some suppliers offering expedited builds within 15 days for single-line models. Cost advantages are significant, with Chinese manufacturers typically providing 25–40% lower pricing than European or North American equivalents due to economies of scale and reduced material overheads.

How to Choose Automatic Bag Making Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Verify adherence to international safety and quality benchmarks such as CE, ISO 9001, and where applicable, RoHS compliance for electronic components. Machines destined for EU or North American markets must meet electrical safety (IEC 60204-1) and mechanical guarding standards. Request documentation on motor efficiency ratings, PLC brands (e.g., Delta, Siemens), and servo system specifications to ensure compatibility with existing production lines.

Production Capacity Assessment

Evaluate infrastructure indicators to confirm scalability:

- Facility size exceeding 3,000m² indicates capacity for batch production

- In-house fabrication capabilities including laser cutting, CNC machining, and welding

- Dedicated R&D teams focused on automation integration and energy optimization

Cross-reference supplier claims with verified performance metrics such as on-time delivery rates (>95%) and reorder frequency to assess reliability.

Customization & Quality Control

Leading suppliers offer configurable options for bag width (up to 1,200mm), material thickness (0.01–0.1mm), output speed (up to 300 pcs/min), and integrated functions like UV printing, gusset forming, or handle punching. Confirm whether customization includes tooling design, PLC programming, and post-delivery calibration. Insist on pre-shipment testing protocols, including 72-hour continuous run trials and video inspections of final assembly stages.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services or letters of credit. Prioritize suppliers with transparent transaction histories, documented after-sales service policies, and multilingual technical support. Sample validation is strongly recommended—request live demonstrations via video call or physical units for performance benchmarking before full procurement.

What Are the Best Automatic Bag Making Machine Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Zhejiang Tianfeng Plastic Machinery Co., Ltd. | Bag Making Machines (206) | US $920,000+ | 100% | ≤8h | 33% | Material, size, logo, lamination, mesh design | $7,800–$20,300 |

| Ruian Win-Win Machinery Co., Ltd. | Bag Making Machines (N/A) | US $520,000+ | 100% | ≤6h | 19% | Color, material, size, label, graphic | $7,800–$20,300 |

| Shenzhen Huachuanggong Machinery Equipment Co., Ltd. | Injection Molding Machines (150) | US $20,000+ | 92% | ≤2h | 50% | Limited data | $495–$10,329 |

| Ruian Xuanhai Machine Co., Ltd. | Bag Making Machines (N/A) | US $30,000+ | 100% | ≤2h | <15% | Color, material, size, packaging, graphic | $4,000–$80,000 |

| Wangxin Heavy Industry Machinery (Jinan) Co., Ltd. | Bag Making Machines (362) | US $130,000+ | 100% | ≤2h | 100% | Material, size, logo, cutting, sewing | $1,280–$11,600 |

Performance Analysis

Wangxin Heavy Industry stands out with a 100% reorder rate and sub-2-hour response time, indicating strong customer retention despite mid-range pricing. Zhejiang Tianfeng leads in product diversity and online sales volume, reflecting robust market penetration and mature export operations. Ruian-based suppliers demonstrate high reliability (100% on-time delivery) and responsiveness, aligning with regional specialization in precision packaging equipment. Shenzhen Huachuanggong offers entry-level pricing but lacks detailed technical disclosures, suggesting potential limitations in after-sales support. For large-scale deployments, prioritize suppliers with proven track records in multi-line configurations, degradable film processing, and automated roll-handling systems.

FAQs

How to verify automatic bag making machine supplier reliability?

Cross-check certifications (ISO, CE) through official registries. Request factory audit reports, equipment test videos, and client references. Analyze transaction history for consistency in delivery performance and dispute resolution outcomes.

What is the typical MOQ and lead time?

Minimum order quantity is typically 1 set. Standard lead times range from 20–40 days depending on machine complexity. Expedited orders may be fulfilled in 15 days for basic single-station models.

Can suppliers customize machines for biodegradable materials?

Yes, several suppliers offer configurations optimized for PLA, PBAT, and other compostable films. Customizations include temperature-controlled sealing bars, anti-static rollers, and low-tension film feeding systems.

Do suppliers provide installation and training?

Most suppliers include remote setup guidance and instructional manuals. On-site commissioning and operator training are often available at additional cost—confirm availability and fees during negotiation.

How to assess machine durability and maintenance needs?

Review build materials (e.g., stainless steel frames, hardened gears), expected uptime (typically 8,000–10,000 hours between major servicing), and spare parts availability. Request mean time between failure (MTBF) data and warranty terms (commonly 12 months).