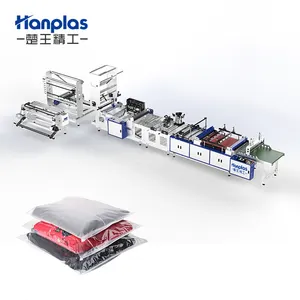

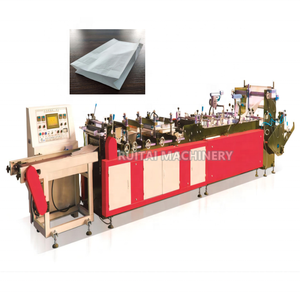

Fully Automatic Bag Making Machine

CN

CN

Top sponsor listing

Top sponsor listing

About fully automatic bag making machine

Where to Find Fully Automatic Bag Making Machine Suppliers?

China remains the global epicenter for fully automatic bag making machine manufacturing, with key production clusters concentrated in Zhejiang, Guangdong, and Hebei provinces. These regions host vertically integrated supply chains encompassing film extrusion, printing, and final packaging machinery assembly. Zhejiang and Guangdong alone account for over 70% of China’s exported plastic and nonwoven bag production equipment, supported by mature industrial ecosystems that streamline component sourcing and reduce lead times.

The clustering effect enables suppliers to offer competitive pricing—typically 25–40% below European or North American manufacturers—while maintaining scalability. Facilities in Ruian (Zhejiang) and Shenzhen (Guangdong) specialize in high-speed t-shirt and shopping bag machines, whereas Hebei-based manufacturers focus on heavy-duty woven polypropylene (PP) and agricultural bag lines. Buyers benefit from localized access to CNC machining, servo-driven control systems, and ultrasonic sealing technologies, ensuring rapid prototyping and customization. Average lead times range from 20–45 days depending on complexity, with standard models often available for immediate dispatch.

How to Choose Fully Automatic Bag Making Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Production Capabilities

Verify machine specifications align with material requirements: LDPE, HDPE, PP, nonwovens, or biodegradable films. Confirm integration of PLC controls, touch-screen HMI interfaces, and servo-driven systems for precision. Prioritize suppliers offering multi-line configurations (e.g., double- or six-lane output) and compatibility with downstream processes like printing or labeling.

Facility and Output Capacity

Assess infrastructure maturity through objective indicators:

- Minimum factory area exceeding 3,000m² to support batch production

- In-house engineering teams capable of customizing sealing patterns, bag dimensions, and feeding mechanisms

- Integration with blown film lines or printing units as value-added offerings

Cross-reference product listing volume and reorder rates to gauge market confidence and production consistency.

Quality Assurance and Compliance

While explicit certification data is not provided, prioritize suppliers demonstrating adherence to international standards via third-party inspections. CE marking is essential for EU market entry, while ISO 9001 indicates structured quality management. Request test reports on critical parameters such as sealing strength, speed accuracy (bags/min), and electrical safety before shipment.

Transaction Reliability Metrics

Leverage performance indicators embedded in supplier profiles:

- On-time delivery rate ≥95% indicates logistical reliability

- Average response time ≤4 hours ensures effective communication

- Reorder rates above 20% reflect customer retention and satisfaction

Utilize escrow-based payment terms and pre-shipment inspections to mitigate risk, particularly for first-time engagements.

What Are the Best Fully Automatic Bag Making Machine Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|

| Zhejiang Allwell Intelligent Technology Co., Ltd. | Bag Making Machines (225), Rotogravure Printers (340) | 100% | ≤4h | - | Color, material, size, logo, packaging, label, graphic | $5,500–$12,000+ | 1 set/unit |

| Shenzhen Huachuanggong Machinery Equipment Co., Ltd. | Filling Machines (123), Sealing Machines (110) | 92% | ≤2h | 50% | - | $495–$10,329 | 1 unit |

| Ruian Nuosheng Machine Co., Ltd. | Blown Film Lines (106), Bag Making Machines (84) | 100% | ≤1h | - | - | $5,500–$12,000 | 1 set |

| Hebei Haosen Leituo Machinery Technology Co., Ltd. | Customization options documented | 100% | ≤3h | 20% | Color, material, size, logo, packaging, label, graphic | $1,200–$250,000 | 1 set |

| Shenzhen Hanbeter Technology Co., Ltd. | Food Processing Machinery (1,699+ listings) | 95% | ≤1h | 17% | - | $9,100–$15,000 | 1 set |

Performance Analysis

Zhejiang Allwell and Ruian Nuosheng demonstrate strong specialization with dedicated bag machine portfolios and 100% on-time delivery, indicating robust production planning. Shenzhen Huachuanggong stands out with a 50% reorder rate—the highest in the dataset—suggesting consistent performance and buyer trust despite a slightly lower on-time rate. Hebei Haosen Leituo offers the widest price spectrum, including high-end industrial systems ($170k+), positioning it for large-scale or specialized deployments. Shenzhen Hanbeter leverages expertise in food-grade applications, evident in bakery and ultrasonic nonwoven models. Buyers seeking integrated solutions should prioritize suppliers with complementary machinery lines (e.g., filling, sealing) to consolidate procurement and reduce integration complexity.

FAQs

What materials can fully automatic bag making machines process?

These machines commonly handle LDPE, HDPE, PP, nonwoven fabrics, and biodegradable polymers. Some models are optimized for specific uses—e.g., food-safe films, woven sacks, or zipper-lock bags—requiring verification of material compatibility prior to purchase.

What is the typical minimum order quantity (MOQ)?

Standard MOQ is one unit or set across all listed suppliers, enabling low-volume trials and small business adoption. Bulk orders may unlock discounted pricing and extended warranty terms.

How long does production and shipping take?

Manufacturing lead time typically ranges from 20–45 days post-deposit, depending on customization level. Sea freight adds 25–40 days for international delivery. Air shipping is rarely used due to machine weight and size.

Can suppliers customize bag dimensions and sealing types?

Yes, most suppliers offer full customization of bag width, length, thickness, and seal style (side, bottom, gusseted). Advanced models support hot knife, impulse, or ultrasonic sealing based on material type.

Do suppliers provide technical support and installation assistance?

While not explicitly stated, high-performing suppliers typically offer remote guidance via video or manuals. On-site commissioning may be available at additional cost—confirm service scope during negotiation.