Automatic Batch Coding Machine

Top sponsor listing

Top sponsor listing

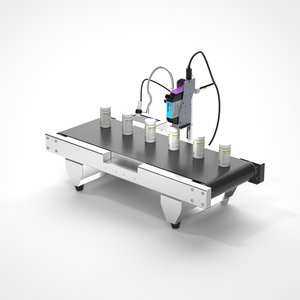

About automatic batch coding machine

Where to Find Automatic Batch Coding Machine Suppliers?

China remains the global epicenter for automatic batch coding machine production, with key manufacturing clusters concentrated in Zhejiang, Hubei, and Guangdong provinces. These regions host vertically integrated supply chains combining precision engineering, inkjet subsystems, and packaging automation expertise. Hangzhou and Yiwu in Zhejiang province specialize in compact, high-speed coding systems optimized for small-to-medium enterprises, leveraging proximity to component suppliers for rapid assembly and testing. Wuhan-based manufacturers focus on industrial-grade TIJ (Thermal Inkjet) and CIJ (Continuous Inkjet) platforms designed for integration into existing production lines.

The regional ecosystems enable cost efficiencies through localized sourcing of printheads, ink cartridges, conveyors, and control systems—reducing material procurement cycles by 25–40% compared to offshore alternatives. Buyers benefit from scalable production capacity, with leading facilities capable of monthly outputs exceeding 500 units. Average lead times range from 15 to 30 days for standard configurations, while customized models require 25–45 days depending on technical complexity. Export readiness is widespread, with most suppliers experienced in international compliance and multimodal logistics coordination.

How to Choose Automatic Batch Coding Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, operational reliability, and transaction security.

Technical & Functional Compliance

Verify that machines support required coding methods—TIJ, CIJ, thermal transfer, or pneumatic stamping—based on substrate type (plastic, glass, metal, cardboard). Ensure compatibility with variable data inputs such as batch numbers, expiry dates, QR codes, and logos. CE certification is a baseline requirement for European markets, while FDA-compliant inks may be necessary for food, pharmaceutical, or medical applications. Evaluate printing resolution (typically 200–600 dpi), character height (1–12.7mm), and line speed (up to 200m/min) against production throughput needs.

Production and Customization Capacity

Assess supplier capabilities through the following indicators:

- Minimum factory area of 2,000m² indicating established production infrastructure

- In-house R&D teams enabling firmware customization, language localization, and interface integration (e.g., PLC, HMI)

- Provision of modular options including dual printheads, conveyor integration, rotary encoders, and sensor-based triggering

- Customization scope covering font design, label layout, ink type (water-resistant, fast-dry, solvent-based), and machine dimensions

Cross-reference product listings with on-time delivery performance (target ≥96%) and response time (ideally ≤4 hours) to gauge operational responsiveness.

Transaction and Quality Assurance

Prioritize suppliers offering verifiable quality control processes, including pre-shipment testing reports and real-time production updates. Use secure payment mechanisms such as escrow services to mitigate risk. Request physical or digital samples to validate print clarity, durability under environmental stress (humidity, temperature), and long-term reliability. Analyze reorder rates—suppliers with rates above 19% indicate consistent customer satisfaction and post-sale support effectiveness.

What Are the Best Automatic Batch Coding Machine Suppliers?

| Company Name | Location | Supplier Type | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Hangzhou Dongning Technology Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Inkjet Printers, Laser Marking Machines, Conveyors, Coding Machines | 100% | ≤4h | 19% | US $200,000+ | Yes |

| Maersky Logo Technology (Guangzhou) Co., Ltd. | Guangdong, CN | Multispecialty Supplier | CIJ Printers, Batch Coding Machines, Packaging Solutions | 100% | ≤1h | 19% | US $190,000+ | Yes |

| Yiwu Jeta International Trading Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | Solid Ink Coders, Embossing Machines, Expiry Date Printers | 100% | ≤4h | <15% | US $220,000+ | Yes |

| Wuhan Willita Industrial Co., Ltd. | Hubei, CN | N/A | Inkjet Printers, Sealing Machines, Laser Marking Systems | 96% | ≤3h | <15% | US $40,000+ | No |

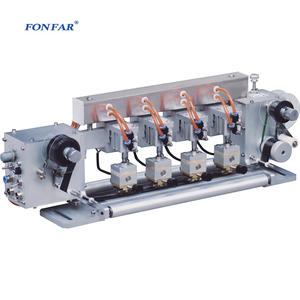

| Jiaozuo Fonfar International Trade Co., Ltd. | Henan, CN | N/A | Hot Stamping Coders, Dry Ink Batch Coders, Labeling Machines | 96% | ≤1h | 19% | US $100,000+ | No |

Performance Analysis

Hangzhou Dongning and Maersky Logo stand out for full customization capabilities and 100% on-time delivery, making them ideal for buyers requiring tailored integration or specialized inks. Maersky’s sub-one-hour response time reflects superior communication efficiency, critical for resolving technical queries during commissioning. Yiwu Jeta offers extensive product variety with solid pricing starting at $215, though its lower reorder rate suggests potential gaps in after-sales service. Wuhan Willita provides competitively priced entry-level models but lacks customization depth. Jiaozuo Fonfar excels in pneumatic and hot-stamp technologies, serving niche applications in rigid packaging sectors. Suppliers with online revenues exceeding US $100,000 demonstrate market validation and sustained export activity.

FAQs

How to verify automatic batch coding machine supplier reliability?

Confirm compliance with CE or equivalent safety standards. Request documentation on printhead lifespan, mean time between failures (MTBF), and ink chemical specifications. Validate supplier claims through third-party transaction records, customer references, and factory audit videos highlighting assembly and testing procedures.

What is the typical minimum order quantity (MOQ)?

Most suppliers set MOQ at 1 set, allowing low-volume trials. Bulk pricing typically applies at 5+ units. Some manufacturers offer sample units at 30–50% above list price, applicable toward future orders.

Do suppliers support OEM/ODM services?

Yes, select manufacturers like Hangzhou Dongning and Maersky Logo provide OEM branding, custom firmware, and private labeling. Lead times for ODM development range from 4 to 8 weeks, depending on software modifications and mechanical redesigns.

What are common lead times and shipping options?

Standard units ship within 15–30 days after order confirmation. Air freight delivers samples in 5–10 days; sea freight for bulk orders takes 25–40 days. FOB terms are standard, though CIF can be arranged upon request.

Can coding machines integrate with existing production lines?

Yes, many models support integration via photoelectric sensors, encoder inputs, and PLC communication (Modbus, I/O signals). Confirm interface compatibility and mounting dimensions before procurement to ensure seamless installation.