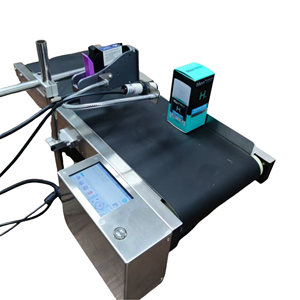

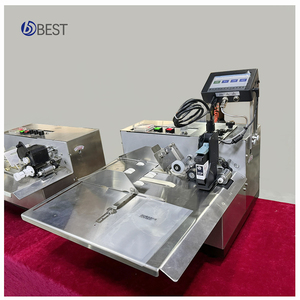

Industrial Batch Coding Machine

1/14

1/14

1/16

1/16

1/16

1/16

1/11

1/11

1/24

1/24

1/12

1/12

1/19

1/19

About industrial batch coding machine

Where to Find Industrial Batch Coding Machine Suppliers?

China remains the central hub for industrial batch coding machine production, with key manufacturing clusters in Hubei, Zhejiang, and Liaoning provinces. Wuhan, in particular, has emerged as a technological epicenter for inkjet and laser coding systems, hosting specialized firms that integrate R&D, component manufacturing, and system assembly under one ecosystem. These regions benefit from established supply chains for printheads, nozzles, UV inks, and conveyor integration components, enabling rapid prototyping and scalable production.

The concentration of technical suppliers within 50km radii allows for vertically integrated operations, reducing lead times by up to 30% compared to decentralized manufacturing models. Buyers gain access to facilities equipped with automated testing rigs for print resolution, adhesion durability, and environmental resistance (e.g., humidity, temperature fluctuation). Average production lead times range from 15–30 days for standard units, with express processing available for urgent orders. Cost efficiencies are notable—localized sourcing reduces unit prices by 20–35% versus equivalent Western-made machines, particularly for thermal inkjet (TIJ) and continuous inkjet (CIJ) configurations.

How to Choose Industrial Batch Coding Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international standards such as CE marking for EU market compliance and ISO 9001-certified quality management systems. Request documentation on printhead longevity tests, ink compatibility matrices, and environmental stress testing (e.g., IP65-rated enclosures for dust/moisture resistance). For food, pharmaceutical, or chemical applications, ensure compliance with FDA or RoHS directives regarding ink formulation and material contact safety.

Production and Customization Capability

Assess supplier infrastructure through verifiable metrics:

- Facility size exceeding 2,000m² indicating capacity for volume output

- In-house engineering teams supporting custom code formats (date/lot/expiry), multi-line printing, QR/barcode generation, and integration with existing production lines

- Support for variable data printing, including real-time database connectivity and anti-counterfeiting serialization

Cross-reference online revenue data and reorder rates as indicators of market trust and product reliability.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party payment protection and post-delivery technical support. Evaluate responsiveness (target ≤4 hours) and availability of remote diagnostics via software interfaces. Confirm inclusion of user training, maintenance manuals, and spare parts inventory. Sample validation is critical—test print clarity, drying time, substrate adhesion, and long-term legibility before full procurement.

What Are the Best Industrial Batch Coding Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Key Offerings |

|---|---|---|---|---|---|---|---|

| Shenyang Faith Technology Co., Ltd. | Liaoning, CN | US $710,000+ | 97% | ≤1h | 22% | $35–$3,800 | CIJ, UV, solvent ink systems; multilingual support; high-speed digital coding |

| Yiwu Jeta International Trading Co,. Ltd. | Zhejiang, CN | US $220,000+ | 100% | ≤4h | <15% | $225–$504 | Budget-friendly TIJ coders; CE-certified models; 2-line expiry date printing |

| Wuhan Xiantong Technology Co., Ltd. | Hubei, CN | US $160,000+ | 100% | ≤5h | 21% | $599–$899 | Handheld electric coders; automatic marking; high-resolution thermal inkjet |

| Lanhai Finenorm Coding Co., Ltd. | Hubei, CN | US $70,000+ | 100% | ≤2h | 20% | $1,900–$5,300 | UV laser coders; TTO printers; OEM thermal transfer solutions |

| Wuhan Willita Industrial Co., Ltd. | Hubei, CN | US $40,000+ | 96% | ≤3h | <15% | $30.80–$469 | Portable TIJ systems; small business packaging coders; compact conveyor integration |

Performance Analysis

Shenyang Faith Technology stands out for high transaction volume and broad technical customization, offering advanced CIJ and UV-curable ink systems suitable for demanding industrial environments. Yiwu Jeta provides cost-effective entry-level TIJ solutions with consistent delivery performance, ideal for SMEs prioritizing affordability and regulatory compliance. Wuhan-based suppliers like Xiantong and Lanhai focus on mid-to-high-end segments, delivering precision inkjet and laser coding equipment with strong after-sales response. Lanhai’s specialization in TTO and UV laser systems positions it well for clients requiring permanent, tamper-proof markings on flexible packaging. Willita targets niche markets with ultra-compact, portable coders at aggressive price points, though lower reorder rates suggest room for service improvement.

FAQs

How to verify industrial batch coding machine supplier reliability?

Cross-check certifications (CE, ISO) with official registries. Request factory audit reports or video walkthroughs highlighting production lines and QC procedures. Analyze customer feedback focusing on print accuracy consistency, ink consumption rates, and technical support responsiveness.

What is the typical MOQ and pricing structure?

Most suppliers offer MOQs of 1 unit, facilitating sample testing and low-volume procurement. Prices vary significantly by technology: handheld TIJ units start at $30, while industrial CIJ or fiber laser systems exceed $2,000. Bulk orders (10+ units) typically qualify for 5–15% discounts and extended warranty terms.

Can suppliers customize coding content and integration?

Yes, reputable manufacturers support dynamic content including batch numbers, expiration dates, barcodes, QR codes, and logos. Integration with PLCs, sensors, and conveyors is standard. Custom firmware development and multi-language interfaces are commonly offered upon request.

Do suppliers provide samples or trial units?

Sample policies vary. Some suppliers offer functional demos at reduced cost, recoverable against future orders. Fully free samples are rare but possible for high-potential buyers. Testing periods typically last 7–14 days, covering print quality, substrate compatibility, and software usability.

What are common shipping and logistics options?

Suppliers generally support global shipping via air or sea freight under FOB, CIF, or DDP terms. Air freight delivers in 5–10 days; sea freight takes 20–40 days depending on destination. Packaging includes shock-resistant crates and moisture barriers, with optional insurance coverage for high-value shipments.