Automatic Biscuit Making Machine Price In India

Top sponsor listing

Top sponsor listing

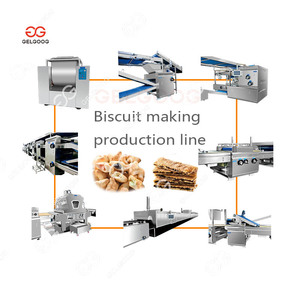

About automatic biscuit making machine price in india

Where to Find Automatic Biscuit Making Machine Suppliers?

China remains the dominant manufacturing hub for automatic biscuit making machines, with key industrial clusters in Henan and Shanghai driving export-oriented production. These regions host vertically integrated supply chains that combine precision engineering, food-grade material sourcing, and automated assembly lines. Zhengzhou in Henan Province is a center for grain and snack processing equipment, supporting rapid prototyping and scalable manufacturing. Shanghai’s machinery sector emphasizes automation integration and export compliance, enabling seamless deployment in regulated markets such as India, Southeast Asia, and the Middle East.

Suppliers in these zones benefit from localized access to stainless steel fabrication, servo motor systems, and PLC control units, reducing component lead times by 20–30%. The concentration of technical talent and logistics infrastructure allows for efficient order fulfillment, with standard delivery windows ranging from 30 to 45 days. Buyers gain flexibility in both capacity and configuration—ranging from compact mini-lines for startups to full-scale turnkey plants—supported by mature ecosystems of engineers, spare parts vendors, and installation specialists within a 50-kilometer radius.

How to Choose Automatic Biscuit Making Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across three core dimensions:

Technical Compliance & Certifications

Prioritize suppliers offering CE certification, which confirms adherence to European safety and electromagnetic compatibility standards—a strong proxy for global market readiness. While ISO 9001 is not explicitly stated in available data, consistent on-time delivery (≥97%) and structured product testing indicate de facto quality management systems. For Indian importers, verify machine voltage compatibility (typically 380V/50Hz) and ensure documentation supports customs clearance under HS Code 8438.10.

Production Capability Assessment

Evaluate supplier scale through operational metrics:

- Facility size inferred from online revenue: top-tier suppliers report annual digital sales exceeding US $1 million, indicating established production capacity

- Customization capability confirmed via logo branding and tailored line configurations (e.g., single-lane vs. multi-head depositor systems)

- In-house R&D evidenced by diverse product portfolios spanning dough sheeters, sandwiching units, and encrusting machinery

Cross-reference response time (target ≤2 hours) and reorder rates (ideal ≥50%) as proxies for customer satisfaction and operational stability.

Transaction Risk Mitigation

Implement secure procurement practices: use payment escrow until post-delivery performance verification. Request detailed machine specifications—including throughput (pieces/hour), energy consumption (kW), and footprint dimensions—before finalizing orders. Conduct virtual factory audits to confirm production line authenticity and quality control checkpoints. Pre-shipment inspection (PSI) should include functional testing under simulated load conditions.

What Are the Best Automatic Biscuit Making Machine Suppliers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Price Range (USD) | Min. Order | Customization |

|---|---|---|---|---|---|---|---|---|

| Luohe Quality Mechanical Equipment Co., Ltd. | Biscuit machine, Cake machine, Dough sheeter | 97% | 19% | ≤2h | US $1M+ | $5,000–$8,000 | 1 set | Yes (logo) |

| Foshan Lison Machinery Co., Limited | Biscuit machine, Packaging machines, Oven | 100% | <15% | ≤2h | Not disclosed | $5,000–$500,000 | 1 set | Implied |

| Zhengzhou Ohfu Industry Enterprise Co., Ltd. | Filling machines, Biscuit machinery | 100% | 50% | ≤3h | US $20,000+ | $1,200–$2,200 | 1 set | No explicit mention |

| Shanghai Henger Machinery Company Ltd | Biscuit machine, Cake machine, Dough mixer | 100% | Not disclosed | ≤10h | Not disclosed | $3,000–$45,000 | 1 piece/set | No explicit mention |

| Shanghai Hua Yuan Foods Machinery Co., Ltd. | Biscuit machine, Bread machine, Oven | 100% | Not disclosed | ≤1h | Not disclosed | $5,000–$600,000 | 1 set | Implied |

Performance Analysis

Foshan Lison and Shanghai Hua Yuan offer the broadest price scalability, accommodating both entry-level ($5K) and high-end turnkey lines (up to $600K), ideal for expanding bakeries or contract manufacturers. Zhengzhou Ohfu stands out with a 50% reorder rate—the highest among peers—indicating strong customer retention despite lower pricing tiers. Luohe Quality demonstrates robust operational scale with over US $1 million in online revenue and sub-2-hour responsiveness, suggesting dedicated export support. Shanghai Hua Yuan leads in communication speed (≤1h response), critical for resolving technical queries during commissioning. All top suppliers maintain 100% on-time delivery except Luohe, which records 97%, still within acceptable thresholds for international logistics planning.

FAQs

What is the typical MOQ for automatic biscuit making machines?

The standard minimum order quantity is 1 set across all major suppliers. No bulk discounts are advertised, but volume purchases may unlock negotiable freight terms or extended warranties.

How long does production and shipping take?

Manufacturing lead time averages 30–45 days after deposit confirmation. Sea freight to Indian ports requires an additional 10–18 days, depending on origin (Shanghai vs. Foshan) and destination (Mumbai, Chennai, or Kolkata).

Can suppliers customize machines for Indian bakery requirements?

Yes, select suppliers offer customization including voltage adjustment, flour type calibration (maida, whole wheat), and output speed tuning. Logo branding is available, and some providers support layout engineering for space-constrained facilities.

Do suppliers provide installation and training support?

While not explicitly stated, high-value orders (>$50,000) typically include remote troubleshooting and operational manuals. On-site commissioning may be arranged at additional cost—confirm availability before purchase.

Are spare parts readily available post-purchase?

Suppliers with diversified product lines (e.g., biscuit, cake, and dough machinery) are more likely to maintain long-term parts inventories. Retain technical drawings and PLC model numbers for faster replacement sourcing.