Automatic Cement Block Making Machine Price In India

CN

CN

Top sponsor listing

Top sponsor listing

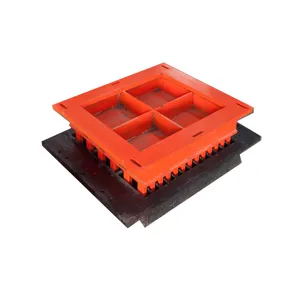

About automatic cement block making machine price in india

Where to Find Automatic Cement Block Making Machine Suppliers?

China remains the dominant global hub for manufacturing automatic cement block making machines, with key production clusters in Shandong and Henan provinces. These regions host vertically integrated industrial ecosystems that support end-to-end production—from raw material processing to final assembly—enabling competitive pricing and scalable output. Shandong, in particular, has emerged as a center for advanced concrete machinery, leveraging proximity to steel suppliers and port infrastructure to reduce logistics costs by 15–20% compared to non-specialized regions.

The concentration of suppliers in these zones allows for rapid component sourcing and streamlined manufacturing cycles. Facilities typically operate under ISO 9001-aligned quality systems, with many offering CE-compliant designs suitable for international markets including India. Buyers benefit from short lead times (average 30–45 days), flexible customization options, and established export channels. The presence of co-located engineering teams, foundries, and logistics providers within 50km radii enhances operational efficiency and supports just-in-time delivery models.

How to Choose Automatic Cement Block Making Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation based on technical, operational, and transactional criteria:

Technical Compliance & Design Capability

Verify adherence to recognized standards such as ISO 9001 or CE marking, particularly for hydraulic systems, electrical controls, and structural integrity. Confirm machine specifications align with local construction requirements in India, including block dimensions (e.g., solid, hollow, paver), production capacity (ranging from 8,000 to 15,000 blocks/day), and compatibility with fly ash, cement, or concrete mixtures. Request detailed technical drawings and control system schematics prior to order placement.

Production Capacity Verification

Assess supplier infrastructure through verifiable metrics:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house fabrication capabilities including CNC machining, welding, and mold design

- Dedicated R&D units supporting customization of block shape, size, vibration frequency, and automation level

Cross-reference online revenue data and reorder rates (where available) with on-time delivery performance to gauge reliability and customer satisfaction.

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as third-party escrow services to mitigate financial risk. Prioritize suppliers with documented after-sales service frameworks, including technician training, spare parts availability, and remote troubleshooting. Conduct pre-shipment inspections either independently or via trusted agents to validate machine functionality against agreed specifications.

What Are the Best Automatic Cement Block Making Machine Suppliers?

| Company Name | Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shandong Shiyue Intelligent Machinery Co., Ltd. | Custom Manufacturer | Brick Making Machinery, Concrete Batching Plant, Mixers | US $1,400,000+ | 100% | ≤3h | 33% | $8,000–$45,900 | Block type, size, color, motor, feeder, solar integration |

| Linyi Shengming Machinery Co., Ltd. | Multispecialty Supplier | Brick Making Machinery, Hydraulic Systems | US $530,000+ | 100% | ≤2h | 44% | $8,000–$45,900 | Hollow block, paver, mobile molds, diesel components |

| Qingdao HF Machinery Technology Co., LTD | Multispecialty Supplier | Concrete Block Machines, Vibration Systems | US $130,000+ | 100% | ≤5h | 28% | $17,900–$45,000 | Material size, pressure settings, label, packaging |

| Gongyi Yayuan Trade Co., Ltd. | Supplier | Brick Making Machinery, Plastic Crushers | US $1,000+ | 100% | ≤2h | - | $1,550–$45,000 | Limited public details |

| Shandong Yinan Tengfei Machinery Co., Ltd. | Supplier | Brick Making Machinery | Not specified | 100% | ≤2h | - | $7,000–$22,000 | Basic model variations |

Performance Analysis

Shandong-based manufacturers dominate in both scale and customization depth. Shandong Shiyue and Linyi Shengming exhibit strong export performance, backed by high reorder rates (33% and 44%, respectively) and robust online transaction volumes. Linyi Shengming stands out for responsiveness (≤2h average reply time) and mid-range pricing, making it a strategic choice for buyers seeking balance between cost and service reliability. Qingdao HF offers premium configurations at higher price points, often targeting clients requiring precise vibration control and hydraulic tuning. Newer entrants like Gongyi Yayuan list entry-level models priced below $2,000, though limited transaction history suggests caution for large-scale procurement without sample validation.

FAQs

What is the typical MOQ and lead time for automatic cement block making machines?

Most suppliers require a minimum order quantity (MOQ) of 1 set. Lead times generally range from 30 to 45 days after deposit confirmation, depending on customization complexity and production load. Expedited orders may be negotiable for standard models.

Can suppliers customize machines for Indian market requirements?

Yes, leading suppliers offer extensive customization, including adaptation to local brick sizes (e.g., 230×110×76 mm), integration of diesel-powered motors for off-grid operation, and modifications for fly ash-based concrete. Some support solar panel integration and pallet-free conveying systems tailored to regional labor and energy conditions.

Do suppliers provide installation and training support?

Many suppliers include basic setup guides and video tutorials. Premium-tier manufacturers offer on-site technician deployment or virtual training sessions covering machine operation, maintenance protocols, and troubleshooting procedures—often included in contracts for orders above $20,000.

How are machines packaged and shipped internationally?

Machines are typically containerized using seaworthy wooden crates or bare load packaging for 20ft or 40ft FCL shipments. Most suppliers coordinate FOB terms from major Chinese ports (e.g., Qingdao, Shanghai). CIF arrangements are available upon request, including insurance and destination handling.

Are samples or test runs available before full purchase?

While full-machine samples are uncommon due to size and cost, suppliers often provide production videos, live factory demonstrations via video call, or small-batch trial runs. Some offer prototype testing for customized configurations, with fees applicable depending on scope.