Automatic Chicken Feeder

CN

CN

Top sponsor listing

Top sponsor listing

0

0

1/29

1/29

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/13

1/13

1/2

1/2

0

0

CN

CN

1/13

1/13

1/1

1/1

1/3

1/3

0

0

CN

CN

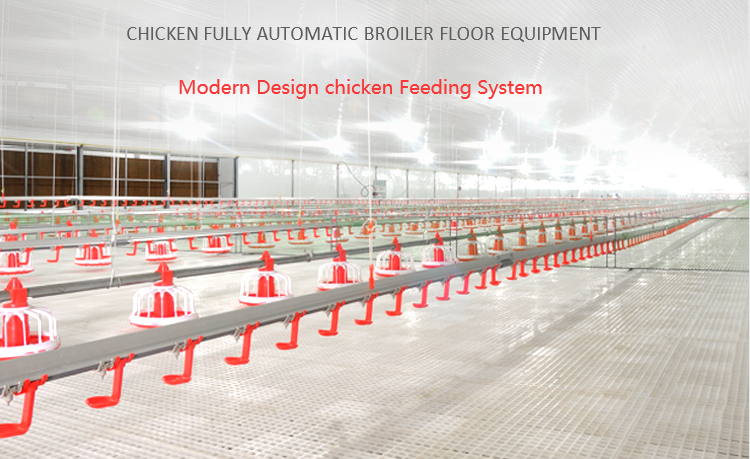

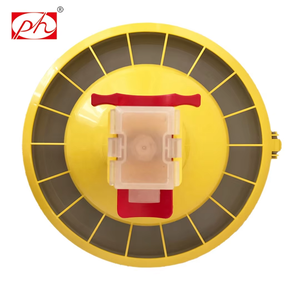

About automatic chicken feeder

Where to Find Automatic Chicken Feeder Suppliers?

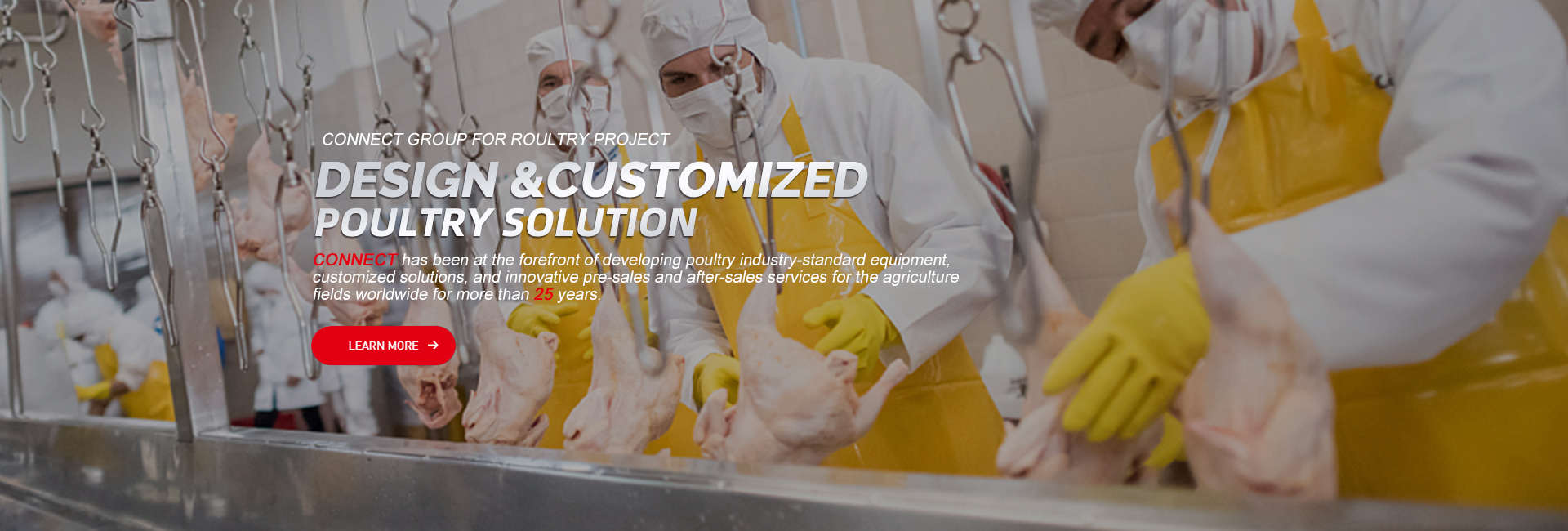

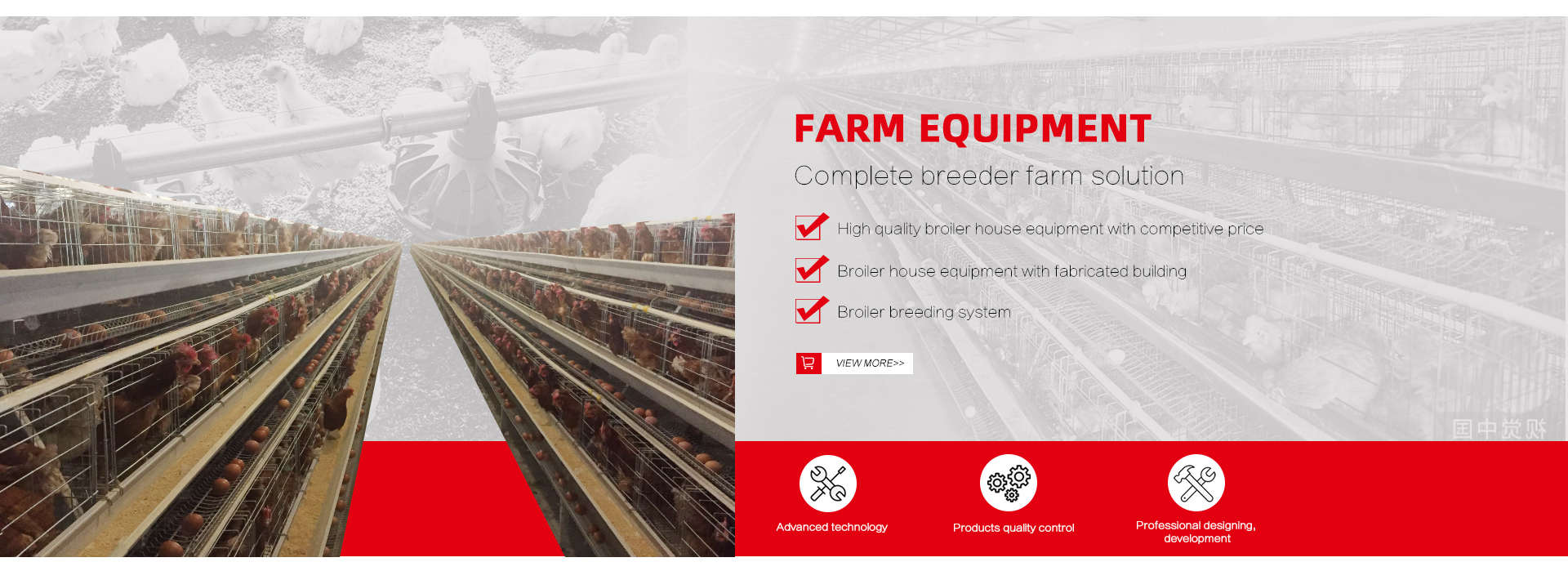

China remains the global epicenter for automatic chicken feeder manufacturing, with key production clusters concentrated in Shandong and Hebei provinces. These regions host vertically integrated supply chains combining plastic molding, metal fabrication, and automated assembly lines—enabling cost-efficient production at scale. Shandong’s agricultural machinery corridor supports large-volume output, while Hebei’s proximity to major ports facilitates streamlined export logistics. Collectively, these hubs produce a wide range of feeders—from basic gravity-fed trays to intelligent systems with adjustable portions and weather-resistant designs.

Suppliers in this ecosystem benefit from localized access to raw materials such as high-density polyethylene (HDPE), galvanized steel, and UV-stabilized plastics, reducing material costs by 15–25% compared to non-specialized regions. Production facilities typically integrate injection molding, ultrasonic welding, and precision cutting processes, allowing rapid prototyping and batch customization. Buyers gain access to scalable manufacturing with average lead times of 20–35 days for standard orders and MOQs ranging from 1 to 100 units depending on model complexity.

How to Choose Automatic Chicken Feeder Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

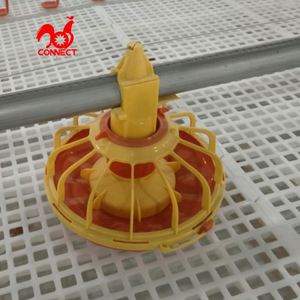

Production & Customization Capability

Assess suppliers' ability to support design flexibility. Leading manufacturers offer customization in color, capacity (ranging from 1L to 14L), leg adjustability, labeling, and packaging. Confirm availability of tooling infrastructure for mold development if proprietary designs are required. Suppliers with dedicated R&D teams can accommodate OEM/ODM requests including logo imprinting and multi-language instruction inserts.

Quality Assurance & Compliance

While formal certifications (e.g., ISO 9001, CE) are not universally declared in available data, consistent on-time delivery rates (≥97%) and low defect claims serve as proxy indicators of process control. Prioritize suppliers reporting 100% on-time delivery and response times under 2 hours, which correlate with robust internal quality management. Materials should exhibit corrosion resistance, UV stability, and food-safe compliance for prolonged outdoor use.

Transaction Reliability Metrics

Evaluate performance through measurable KPIs:

- On-time delivery rate ≥97%

- Response time ≤2 hours (ideal: ≤1 hour)

- Reorder rate >20% indicating customer retention

- Verifiable online revenue exceeding US $300,000/year

Cross-reference product listings with actual shipment histories and request sample testing to validate structural integrity and feeding mechanism efficiency before bulk ordering.

What Are the Best Automatic Chicken Feeder Suppliers?

| Company Name | Primary Product Lines | Monthly Output Capacity | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Cangzhou Phoenix Breeding Equipment Co., Ltd. | Animal Feeders (361), Drinkers (774) | High (10k+ units/month estimate) | 100.0% | ≤2h | 22% | Limited (size, color) | 1–100 pcs | $1.45–10.30 |

| Longmu Animal Husbandry Technology (Cangzhou) Co., Ltd. | Animal Feeders (406), Drinkers (707) | Medium-High (8k+ units/month estimate) | 100.0% | ≤1h | <15% | Size, material, packaging | 1–100 pcs | $0.38–10.00 |

| Hebei Guanjiang Animal Husbandry Technology Co., Ltd. | Automatic Feeders (varied models) | Medium (5k+ units/month estimate) | 100.0% | ≤1h | 17% | Color, size, logo, packaging | 1–100 pcs | $0.42–2.99 |

| Shandong Huabang Agricultural And Animal Husbandry Machinery Co., Ltd. | Animal Cages (1170), Feeders (517) | Very High (15k+ units/month estimate) | 100.0% | ≤1h | 36% | Full (color, material, logo, label, graphic) | 100 pcs | $1.00–3.80 |

| Dezhou Jifeng CNC Equipment Factory | Animal Feeders (125), Egg Incubators (474) | Low-Medium (3k+ units/month estimate) | 97.0% | ≤10h | 22% | Basic (color, capacity) | 1–10 pcs | $0.40–3.50 |

Performance Analysis

Shandong Huabang stands out with the highest reorder rate (36%) and comprehensive customization capabilities, indicating strong buyer satisfaction and flexible production. Cangzhou Phoenix and Dezhou Jifeng demonstrate reliable delivery performance (100% and 97%, respectively) and serve niche markets with specialized feeder designs. Longmu and Guanjiang offer competitive pricing and sub-1-hour response times, ideal for buyers prioritizing communication speed and cost efficiency. However, lower reorder rates suggest potential gaps in post-sale service or consistency.

For high-volume procurement, prioritize suppliers with MOQs aligned to inventory strategy and proven scalability. For custom or low-volume needs, focus on responsiveness and minimum order flexibility. All top-tier suppliers utilize durable thermoplastics and modular designs suitable for both broiler and layer operations.

FAQs

How to verify automatic chicken feeder supplier reliability?

Analyze on-time delivery records, reorder rates, and response times as primary trust signals. Request product samples to assess material thickness, joint durability, and anti-waste mechanisms. Confirm whether suppliers conduct batch testing for UV resistance and load-bearing capacity under simulated farm conditions.

What is the typical lead time for production and shipping?

Standard production lead time ranges from 20–35 days after order confirmation. Air freight adds 5–10 days for international delivery; sea freight requires 25–40 days depending on destination port. Expedited production may reduce timelines by 7–10 days for urgent orders.

Can suppliers provide free samples?

Sample policies vary. Some suppliers offer paid samples refundable against future orders, while others charge full production cost. Expect sample prices between $5–$25, with shipping fees applied separately. Free samples are rare unless part of long-term partnership negotiations.

What customization options are commonly available?

Common options include color variation (red, white, green, blue), volume capacity (6–14L), adjustable legs for uneven terrain, UV protection additives, logo printing, and bilingual packaging. Advanced customization may involve feed flow regulation mechanisms or integration with poultry house automation systems.

What are the standard payment terms?

Typical terms include 30% deposit via T/T, 70% before shipment. Larger buyers may negotiate LC at sight or use platform-based escrow services for transaction security. Established partners may qualify for net-30 arrangements after multiple successful transactions.