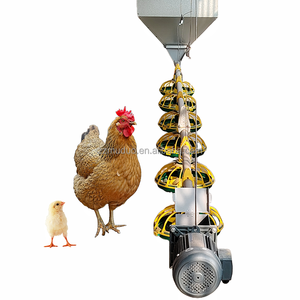

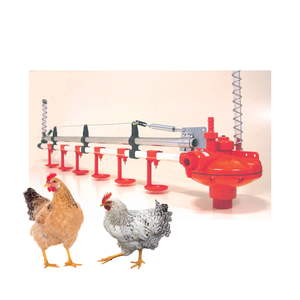

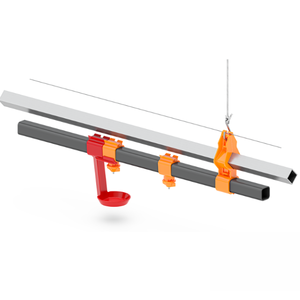

Automatic Feeder

1/3

1/3

1/3

1/3

1/16

1/16

1/9

1/9

0

0

1/29

1/29

1/20

1/20

HK

HK

1/3

1/3

1/3

1/3

CN

CN

1/23

1/23

0

0

0

0

1/3

1/3

1/3

1/3

1/3

1/3

About automatic feeder

Where to Find Automatic Feeder Suppliers?

China leads global production of automatic feeders, with specialized manufacturing clusters in Hebei, Henan, and Zhejiang provinces enabling competitive pricing and scalable output. Hebei’s Shijiazhuang region hosts compact, agile suppliers focused on pet care products, leveraging proximity to raw material hubs for rapid prototyping. Henan, particularly Zhengzhou, serves as a center for agricultural-grade feeding systems, supported by integrated plastics and metal fabrication networks that reduce component costs by 15–25%. Zhejiang’s Hangzhou cluster emphasizes smart pet technology, combining IoT integration with streamlined assembly processes.

These regional ecosystems offer buyers access to vertically aligned supply chains—encompassing injection molding, electronics integration, and packaging—within concentrated geographic zones. This localization supports lead times averaging 20–35 days for standard orders and enables cost efficiencies of 20–30% compared to Western or Southeast Asian manufacturers. Suppliers in these regions typically maintain in-house design teams and automated production lines, facilitating both high-volume runs and low-MOQ customized solutions.

How to Choose Automatic Feeder Suppliers?

Procurement decisions should be guided by structured evaluation criteria:

Product & Process Compliance

Verify adherence to material safety standards such as FDA-approved PP, UV-resistant polymers, and BPA-free plastics—critical for pet food contact applications. While formal ISO 9001 certification is not universally listed, prioritize suppliers demonstrating quality control through documented testing procedures, batch traceability, and third-party inspection options.

Production Capacity & Customization Capability

Assess operational scale and flexibility:

- Suppliers with >100 product listings in pet feeders indicate established specialization

- Dedicated R&D capabilities confirmed via customization options (e.g., RFID sensors, cloud storage, motor types, laser engraving)

- In-house tooling and mold-making capacity allows faster iteration for private-label designs

Cross-reference online revenue metrics (e.g., US $500,000+ annual volume) and reorder rates (>15%) as proxies for market validation and reliability.

Transaction Reliability Indicators

Prioritize partners with verified performance data: on-time delivery ≥96%, response time ≤5 hours, and reorder rates above industry averages. Use minimum order quantities (MOQs) as leverage—many suppliers accept MOQs as low as 1–2 pieces for initial sampling, enabling risk-mitigated testing before scaling.

What Are the Best Automatic Feeder Suppliers?

| Company Name | Location | Main Product Focus | Listings (Feeders) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Hangzhou Cute Pet Technology Co., Ltd. | Zhejiang, CN | Smart Cat Feeders | 3 | US $790,000+ | 96% | ≤5h | 21% | Motor, battery, RFID, cloud storage, laser design, UV sticker, packaging |

| Zhengzhou Jinhui Agricultural S&T Co., Ltd. | Henan, CN | Poultry & Livestock Feeders | 5 | US $570,000+ | 99% | ≤2h | 19% | Color, size, capacity, automation level, patented design, packaging |

| Chengdu Tops Technology Co., Ltd. | Sichuan, CN | Pet & Fish Feeders | 3 | US $460,000+ | 99% | ≤3h | 16% | Color, material, size, logo, packaging, graphic |

| Shijiazhuang Jinshine Technology Co., Ltd. | Hebei, CN | Pet Bowls & Feeders | 3 | US $10,000+ | 100% | ≤2h | 15% | Limited (implied via main product focus) |

| PET HIGH International Industrial Company., Limited | Guangdong, CN | Pet Feeders & Accessories | 3 | US $7,000+ | 100% | ≤2h | <15% | Not specified |

Performance Analysis

Hangzhou Cute Pet Technology stands out for advanced smart feeder capabilities, offering cloud connectivity and sensor-based dispensing, supported by a 21% reorder rate—the highest among peers. Zhengzhou Jinhui dominates agricultural feeding solutions with scalable MOQs (50–100 units), sub-2-hour responses, and extensive customization for farm use. Chengdu Tops demonstrates balanced versatility across pet and aquatic feeders with moderate customization depth. Smaller suppliers like Shijiazhuang Jinshine and PET HIGH achieve perfect on-time delivery records but exhibit lower transaction volumes, suggesting niche or early-stage operations. Buyers seeking innovation should prioritize suppliers with technical feature lists (e.g., RFID, microwave-safe materials); those requiring bulk poultry systems should target Henan-based manufacturers with proven scalability.

FAQs

What are typical MOQs for automatic feeders?

MOQs range from 1 piece for retail-ready models to 50–100 units for industrial or customized variants. Smart feeders often require 2-piece minimums, while agricultural systems may mandate higher volumes for cost efficiency.

How long do production and shipping take?

Standard production lead time is 20–30 days post-sample approval. Air freight adds 5–10 days for international delivery; sea freight requires 25–40 days depending on destination. Expedited processing (10–15 days) is available from select suppliers at premium cost.

Can suppliers provide custom branding and packaging?

Yes, most suppliers listed offer OEM/ODM services including logo printing, color variation, custom packaging boxes, and user manual localization. Advanced options include laser engraving, graphic redesign, and molded-in labels.

Are electronic components reliable in smart feeders?

Reliability varies by supplier. Top-tier vendors specify battery backup, power-off memory retention, and app stability. Request firmware version details and compatibility (iOS/Android) during due diligence. Independent lab testing is recommended for mission-critical deployments.

Do suppliers support sample orders?

All listed suppliers permit sample purchases, typically at 1–2 pieces with no MOQ restriction. Sample costs usually reflect near-retail pricing and may be partially credited toward future bulk orders.