Automatic Chips Making Machine

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About automatic chips making machine

Where to Find Automatic Chips Making Machine Suppliers?

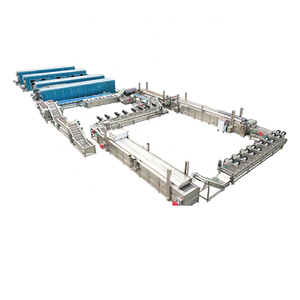

China remains the central hub for automatic chips making machine manufacturing, with key industrial clusters concentrated in Shandong, Henan, and Jiangsu provinces. These regions host vertically integrated supply chains encompassing stainless steel fabrication, food-grade component machining, and automated control systems integration. Shandong stands out for its specialization in full-scale snack food processing lines, supported by proximity to agricultural zones producing potatoes, plantains, and sweet potatoes—critical raw materials for chip production.

The ecosystem enables suppliers to offer scalable solutions—from compact 250kg/h units for small enterprises to fully automated 1,000kg/h industrial lines. Integrated logistics networks reduce component sourcing lead times by up to 30%, while localized engineering talent supports rapid prototyping and customization. Buyers benefit from competitive pricing structures, with standard automatic chips machines ranging from $3,500 to $15,800, and high-capacity or customized systems exceeding $50,000. Lead times typically range between 20–45 days depending on configuration complexity and order volume.

How to Choose Automatic Chips Making Machine Suppliers?

Effective supplier selection requires a structured evaluation of technical capability, operational reliability, and transactional transparency:

Technical Compliance & Material Standards

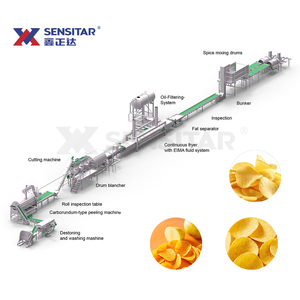

Verify that equipment is constructed using food-grade stainless steel (typically SUS304 or equivalent) and complies with international hygiene standards. While explicit ISO or CE certifications are not always listed, suppliers should provide documentation confirming adherence to electrical safety norms and thermal system stability. Machines must support HACCP-compliant operations, particularly in frying, drying, and seasoning modules.

Production Capacity Verification

Assess infrastructure indicators such as factory size, R&D capacity, and production line diversity. Key benchmarks include:

- Minimum facility area of 3,000m² for reliable batch production

- Demonstrated experience in food processing lines (evidenced by product listing volume)

- In-house engineering teams capable of customizing cutting, frying, and packaging modules

Cross-reference output claims with actual product listings and declared capacities (e.g., 500kg/h, 1,000kg/h).

Transaction Reliability Indicators

Prioritize suppliers with verifiable performance metrics: on-time delivery rates ≥96%, response times under 3 hours, and reorder rates above 25%. These KPIs reflect operational efficiency and post-sale satisfaction. Use documented revenue ranges (where available) as proxies for market presence and export experience. For higher-value transactions, request third-party inspection reports or video audits prior to payment release.

What Are the Best Automatic Chips Making Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Luohe Orange Mechanical Equipment Co., Ltd. | Henan, CN | Other Snack Machines (1,078) | 96% | ≤3h | 24% | $3.1M+ | Color, material, size, logo, packaging, label, graphic | $720–$72,000 |

| Changzhou Zhongxue Refrigeration Equipment Co., Ltd. | Jiangsu, CN | Not specified | 100% | ≤1h | 50% | $10K+ | Color, material, size, logo, packaging, label, graphic | $720–$72,000 |

| GELGOOG CO., LTD | Fujian, CN | Food Processing Lines (493) | – | ≤2h | – | – | Not specified | $6,000–$13,990 |

| Shandong Shengkang Shengshi Intelligent Equipment Machinery Co., Ltd. | Shandong, CN | Potato Chips Making Machine (107) | 100% | ≤1h | – | $30K+ | Not specified | $8,000–$46,800 |

| Shandong Sunmachine International Co., Ltd. | Shandong, CN | Food Processing Lines (585) | 75% | ≤4h | 27% | $50K+ | Factory-customized configurations | $3,500–$4,500 |

Performance Analysis

Changzhou Zhongxue and Shandong Shengkang demonstrate strong operational reliability with 100% on-time delivery and sub-2-hour response times, indicating robust internal coordination. Changzhou Zhongxue’s 50% reorder rate suggests exceptional customer retention, likely driven by responsive service and consistent quality. Luohe Orange leads in scale with over $3.1 million in reported online revenue and extensive product diversification across snack and drying equipment, positioning it as a high-volume exporter.

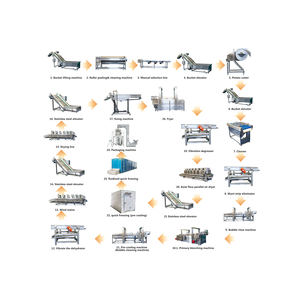

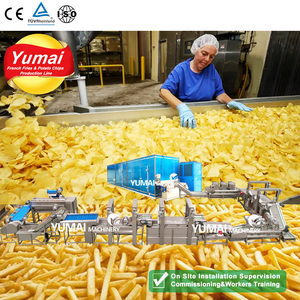

Shandong-based suppliers dominate in application-specific expertise, particularly in potato and plantain chip processing lines. However, Shandong Sunmachine’s 75% on-time delivery rate presents a potential risk for time-sensitive deployments. GELGOOG offers mid-range pricing but lacks transparency in delivery and reorder metrics, warranting additional due diligence. Buyers seeking premium automation should prioritize suppliers offering end-to-end line integration, including peeling, slicing, frying, seasoning, and packaging modules.

FAQs

How to verify automatic chips making machine supplier reliability?

Evaluate suppliers based on response consistency, delivery track record, and breadth of product offerings. Request machine specifications, material certifications, and optional third-party inspection reports. Video walkthroughs of operational units can validate functionality and build quality.

What is the typical MOQ and lead time?

Minimum Order Quantity is typically 1 set, facilitating pilot procurement. Standard lead times range from 20 to 45 days post-payment, depending on customization level. Expedited builds may be possible for non-modified models.

Can these machines handle different raw materials?

Yes, most automatic chips making machines are engineered for multi-material processing, including potatoes, sweet potatoes, bananas, plantains, and root vegetables. Adjustments to blade type, fryer temperature, and conveyor speed allow for process optimization across substrates.

Do suppliers offer customization options?

Multiple suppliers provide customization in machine dimensions, output capacity, material finish (e.g., SUS304), control panel language, and branding elements such as color, logo, and packaging design. High-end models support PLC integration and IoT-enabled monitoring for smart factory deployment.

What are the common payment and shipping terms?

Payment terms typically include T/T (bank transfer), with partial deposits required upfront. Shipping is commonly arranged FOB, though some suppliers support CIF arrangements. Sea freight is standard for full machinery shipments due to weight and dimensional constraints; air freight is viable only for compact models.