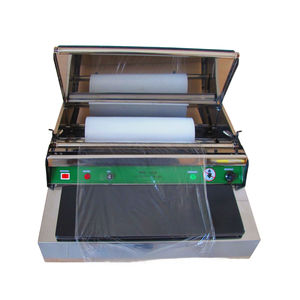

Automatic Cling Wrap Machine

Top sponsor listing

Top sponsor listing

CN

CN

About automatic cling wrap machine

Where to Find Automatic Cling Wrap Machine Suppliers?

China remains the global epicenter for automatic cling wrap machine manufacturing, with key production clusters concentrated in Zhejiang, Guangdong, and Shandong provinces. These regions host vertically integrated supply chains encompassing film extrusion, rewinding, and packaging automation, enabling streamlined production of end-to-end wrapping solutions. Wenzhou in Zhejiang specializes in intelligent packaging systems, leveraging proximity to component suppliers for servo motors, control panels, and sealing units, reducing lead times by 20–30% compared to decentralized markets.

The industrial ecosystems support both high-volume OEM output and engineered-to-order machines, with factories averaging 3,000–25,000m² in size. Localized access to raw materials—such as LLDPE, PVC, and PET films—and precision machining services allows suppliers to maintain cost efficiency, with production costs estimated 25–40% below European or North American counterparts. Buyers benefit from rapid prototyping capabilities, scalable assembly lines, and modular designs adaptable to food, logistics, and retail packaging applications.

How to Choose Automatic Cling Wrap Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and transactional security:

Technical & Production Capabilities

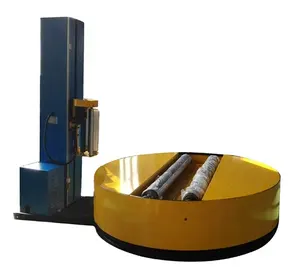

Prioritize suppliers with documented expertise in automated packaging systems. Key indicators include dedicated R&D teams, in-house engineering for control systems (PLC/HMI integration), and proven experience in horizontal/vertical wrapping configurations. Factories with over 50 listed packaging machine models demonstrate product maturity and design iteration. Confirm compatibility with film types (PE, PVC, POF) and load dimensions (up to 2,500mm height, 1,800kg pallet weight) based on operational requirements.

Quality Assurance Metrics

Evaluate performance through verifiable operational data:

- On-time delivery rate ≥97% indicates reliable production planning

- Average response time ≤2 hours reflects strong customer engagement

- Reorder rate below 15% may suggest niche specialization; rates above 25% indicate high satisfaction

- Minimum 10,000 USD annual online revenue signals consistent market presence

Certifications such as ISO 9001 and CE are essential for quality management and international compliance, though explicit documentation should be requested during due diligence.

Customization and Transaction Safeguards

Leading suppliers offer customization in film tension control, wrapping speed (up to 60 cycles/hour), color schemes, branding (logo, labeling), and integration with conveyor systems. Verify these options through direct consultation. Use secure payment mechanisms—preferably third-party escrow—and request pre-shipment inspection protocols. Sample testing is recommended to evaluate sealing integrity, film consumption efficiency, and operational noise levels before scaling orders.

What Are the Best Automatic Cling Wrap Machine Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue (USD) | Customization Options | Notable Product Range |

|---|---|---|---|---|---|---|---|

| Wenzhou Aimesk Intelligent Equipment Co., Ltd. | Wrapping Machines (N/A) | 99% | ≤2h | <15% | $310,000+ | Color, material, size, logo, packaging, label, graphic | AR25 Series ($24K), Super-X Desktop Models ($2.7K) |

| Xingtai Zhipan Machinery Manufacturing Factory | Wrapping Machines (311) | 100% | ≤1h | 28% | $10,000+ | Material, size, color, logo, packaging | Pallet Wrappers ($1,166), Circular Packaging Systems ($800) |

| Shandong Better Onward Machinery Co., Ltd. | Wrapping Machines (380) | 94% | ≤9h | 15% | $30,000+ | Size, material, logo, packaging | F15B Pro ($9.5K), AR25 Food Tray Model ($19.9K) |

| GUANGDONG XINHUIDA MACHINERY TECHNOLOGY GROUP CO., LTD. | Rewinding Machines (54), Extruders (212) | 100% | ≤9h | <15% | $50,000+ | Material, size, pallet height, weight, packaging | Film Making Lines ($80K), Rewinders ($3.8K) |

| Shanghai Taole Machine Co., Ltd. | Wrapping Machines (48) | 87% | ≤3h | <15% | $170,000+ | Pallet specs, color, material, logo, packaging | Multipurpose Wrapping Systems ($2K–$10K range) |

Performance Analysis

Wenzhou Aimesk stands out with a 99% on-time delivery rate and sub-2-hour response time, supported by high transaction volume ($310K+ revenue), indicating robust operational capacity. Xingtai Zhipan excels in responsiveness (≤1h) and customer retention (28% reorder rate), suggesting strong post-sale satisfaction despite lower reported revenue. Shandong Better Onward offers extensive product diversity with 380 wrapping machine listings, though its 94% delivery rate warrants closer logistics scrutiny. Guangdong Xinhuida targets upstream production with film extrusion and rewinding systems, ideal for buyers integrating film manufacturing with packaging. Shanghai Taole maintains high sales volume but lags in delivery performance (87%), which may impact time-sensitive deployments.

FAQs

What is the typical MOQ and pricing range for automatic cling wrap machines?

Minimum order quantity is typically 1 set or unit. Pricing varies by automation level: desktop models start at $2,000–$2,800, mid-range semi-automatic systems range from $8,700–$10,000, while fully automatic high-speed lines reach $18,000–$28,000. Film extrusion and rewinding systems exceed $39,000, with some lines priced above $80,000.

How long does production and shipping take?

Standard lead time ranges from 15 to 30 days after order confirmation, depending on customization complexity. Shipping via sea freight adds 20–40 days for international destinations. Air freight reduces transit time to 5–10 days but increases costs significantly for heavy machinery.

Can suppliers provide CE-certified machines?

Yes, reputable suppliers offer CE-compliant models designed for export to Europe and other regulated markets. Request certification documentation and verify conformity with EN 415 and EN 14238 safety standards for packaging machinery.

Do suppliers support OEM/ODM services?

Most leading suppliers provide OEM branding (custom logos, colors, labels) and ODM modifications including wrapping dimensions, control panel language, voltage specifications (220V/380V), and integration with existing production lines.

What are common customization parameters?

Buyers can customize film type compatibility, load dimensions (height, weight), wrapping speed, turntable diameter, control interface (touchscreen, PLC brand), power source, and safety enclosures. Additional features include pre-stretch film carriages, automatic film cutting, and IoT-enabled monitoring systems.