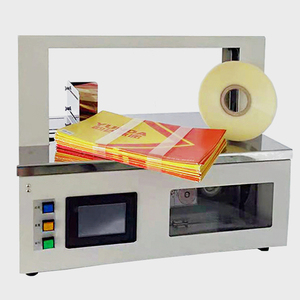

Automatic Box Wrapping Machine

Top sponsor listing

Top sponsor listing

CN

CN

About automatic box wrapping machine

Where to Find Automatic Box Wrapping Machine Suppliers?

China remains the global epicenter for automatic box wrapping machine manufacturing, with key production clusters in Shandong, Jiangsu, and Guangdong provinces. These regions host vertically integrated facilities that combine precision engineering with scalable output, enabling competitive pricing and rapid fulfillment. Shandong’s Jining and Jinan zones specialize in heavy-duty packaging automation, supported by regional steel and conveyor component suppliers that reduce material costs by 15–20%. Meanwhile, Suzhou and Foshan serve as innovation hubs, focusing on servo-driven control systems, film tension optimization, and multi-format compatibility for diverse carton dimensions.

The industrial ecosystems in these areas offer buyers access to mature supply chains where R&D, machining, assembly, and testing occur within tightly coordinated networks. Facilities typically span 3,000–24,000m², supporting monthly outputs ranging from 50 to over 300 units depending on automation level. This integration translates into lead times of 20–40 days for standard configurations, with customization cycles extending up to 50 days for specialized control panels, strapping systems, or integrated conveyors. Export-ready infrastructure ensures compliance with international logistics standards, facilitating shipments to North America, Europe, and Southeast Asia.

How to Choose Automatic Box Wrapping Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional criteria:

Technical Compliance & Quality Assurance

Verify adherence to international quality frameworks such as ISO 9001. While not always explicitly stated, CE marking is essential for European market entry and indicates compliance with electrical safety and machinery directives. Request documentation for motor efficiency ratings, PLC controller specifications (e.g., Mitsubishi, Siemens), and film pre-stretch performance metrics. Machines handling high-speed operations (≥40 cycles/hour) should include overload protection and real-time fault diagnostics.

Production Capability Assessment

Evaluate supplier capacity through verifiable indicators:

- Facility size exceeding 3,000m² to support dedicated assembly lines

- In-house engineering teams capable of modifying turntable diameter, conveyor height, film carriage design, and control interface language

- Customization scope covering film type (LLDPE stretch, PP strap, heat-shrink), power phase (single/three-phase), and integration with upstream case sealers or palletizers

Cross-reference online revenue data and product listing volume to assess scale. Prioritize suppliers with on-time delivery rates above 97% and response times under 4 hours.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services to align payment milestones with delivery and inspection. Analyze reorder rates as a proxy for customer satisfaction—suppliers exceeding 25% indicate consistent performance. Request sample testing to validate sealing consistency, film breakage frequency, and alignment accuracy across variable load weights (typically 5–80 kg). Confirm warranty terms covering core components like gearboxes, motors, and control boards (standard: 12 months).

What Are the Best Automatic Box Wrapping Machine Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Product Range Highlights |

|---|---|---|---|---|---|---|

| Jining Shunyin Machinery Co., Ltd. | Wrapping Machines (733) | 98% | 25% | ≤2h | US $690,000+ | Conveyor integration, turntable customization, multilingual control panels, plastic/PP strapping systems |

| Suzhou Yunmeijia Intelligent Technology Co., Ltd. | Multi-Function Packaging Machines (124) | 50% | <15% | ≤4h | US $30,000+ | Automatic tape sealing, stretch wrapping combos, compact footprint models |

| Shandong Yizhou Science And Technology Development Co., Ltd. | Wrapping Machines (1052) | 97% | 31% | ≤2h | US $120,000+ | Semi-automatic to full-auto variants, film pre-stretch adjustment, customizable ramp and load height |

| Foshan Dession Packaging Machinery Co., Ltd. | Multi-Function Packaging Machines (297) | 100% | 20% | ≤5h | US $220,000+ | Cellophane overwrapping, cosmetic/pharma-grade finishing, high-speed thermal sealing |

| Guangzhou Kemeirui Machinery Equipment Co., Ltd. | Wrapping Machines (54) | 100% | 25% | ≤2h | US $30,000+ | High-speed cellophane/BOPP overwrapping, automated folding systems for luxury packaging |

Performance Analysis

Jining Shunyin and Shandong Yizhou lead in product diversity and reorder performance, with the latter achieving a 31% repeat order rate—indicative of strong post-sale reliability. Foshan Dession and Guangzhou Kemeirui focus on premium cellophane-based solutions for cosmetics and pharmaceuticals, commanding higher price points ($4,000–$15,000) due to precision folding and heat-sealing technology. Suzhou Yunmeijia, despite lower on-time delivery (50%), offers competitively priced combo machines integrating sealing and wrapping functions, suitable for SMBs seeking space-efficient solutions. Buyers prioritizing reliability should select suppliers with 97%+ on-time delivery and documented customization experience, particularly for non-standard box sizes or integration with existing lines.

FAQs

What is the typical MOQ for automatic box wrapping machines?

Most suppliers set a minimum order quantity (MOQ) of 1 unit, allowing buyers to test performance before scaling. Bulk orders (5+ units) may unlock negotiated pricing and extended warranties.

How long does it take to receive a customized machine?

Standard models ship within 20–30 days. Customized systems requiring modified turntable diameter, control software localization, or integrated sensors require 35–50 days, including factory acceptance testing (FAT).

Can these machines handle different box sizes and weights?

Yes, most automatic models support adjustable turntables (diameter: 800–1800mm) and programmable film carriages. Load capacity typically ranges from 5–80kg, with some industrial variants supporting up to 150kg using reinforced frames and dual-film dispensers.

Do suppliers provide installation and training support?

Many offer remote setup guidance via video and manuals. On-site commissioning is available upon request, often at additional cost. Ensure pre-delivery review of electrical requirements (voltage, phase) and facility layout clearance.

What customization options are commonly available?

Key configurable parameters include film type (stretch, shrink, cellophane), strapping width (10–15mm), control panel language (English, Spanish, Russian), conveyor length, and automation level (semi-auto vs. fully automatic with sensor-triggered start).