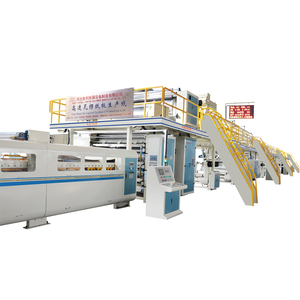

Automatic Corrugated Box Making Machine

Top sponsor listing

Top sponsor listing

CN

CN

About automatic corrugated box making machine

Where to Find Automatic Corrugated Box Making Machine Suppliers?

China remains the global epicenter for automatic corrugated box making machine production, with key manufacturing clusters in Shandong and Hebei provinces driving innovation and scale. Shandong, particularly cities like Jinan and Qingdao, hosts advanced CNC-based machinery manufacturers that integrate automation and PLC control systems into high-speed packaging lines. Hebei’s Cangzhou region specializes in cost-effective, modular machines tailored for 3-ply to 7-ply cardboard processing, benefiting from proximity to major paperboard and steel suppliers that reduce material lead times by up to 25%.

These industrial hubs feature vertically integrated ecosystems where casting, machining, assembly, and testing occur within consolidated facilities. This structure enables rapid prototyping, batch customization, and scalable output—critical for buyers requiring consistent delivery of complex machinery. Average factory areas exceed 5,000m², supporting monthly outputs ranging from 20 to 100 units depending on automation level. Buyers benefit from localized supply chains that cut production costs by 20–35% compared to European or North American equivalents, while maintaining compliance-ready designs for international markets.

How to Choose Automatic Corrugated Box Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Confirm adherence to international safety and performance standards such as CE and ISO 9001. Machines must support specified ply ranges (commonly 3–7 layers), die-cutting precision (±0.5mm), and gluing uniformity. Verify inclusion of PLC controls, servo-driven feeding systems, and HMI interfaces. Request design validation documentation, including electrical schematics and structural load testing reports.

Production Capacity Verification

Assess infrastructure indicators:

- Minimum factory footprint of 3,000m² for sustained volume output

- In-house engineering teams capable of customizing machine width (e.g., 1600–2800mm), speed (up to 200 boxes/min), and integration with printing or slotting modules

- On-site CNC machining, welding, and heat treatment capabilities

Cross-reference these assets with on-time delivery rates above 94% and response times under 6 hours to ensure operational reliability.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party payment protection and post-delivery commissioning assistance. Evaluate warranty terms (typically 12 months) and availability of remote diagnostics or technician dispatch. Analyze reorder rates as a proxy for customer satisfaction—rates exceeding 30% indicate strong service performance. Conduct video audits of production lines before finalizing orders to verify process maturity.

What Are the Best Automatic Corrugated Box Making Machine Suppliers?

| Company Name | Location | Verified Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shandong Yuchen Cnc Co., Ltd. | Shandong, CN | Custom Manufacturer | Paper Processing Machinery, Foam/Plastic/Cloth Cutting Machines | $300,000+ | 94% | ≤1h | 33% | $15,000–$50,000 |

| Dongguang Xinlong Packaging Machinery Co., Ltd. | Hebei, CN | — | Carton Printing Slotting Die-Cutting Machinery, Gluing Machines | $60,000+ | 100% | ≤5h | <15% | $18,500–$170,000 |

| Cangzhou Ipack Machinery Manufacture Co., Ltd. | Hebei, CN | Custom Manufacturer | Automatic Glue Machines, Corrugated Carton Equipment | — | 100% | ≤6h | — | $12,500–$28,600 |

| Cangzhou Kingsun Imp. & Exp. Co., Ltd. | Hebei, CN | Multispecialty Supplier | Fully Automatic Flexo Printers, Box Packing Systems | $1,300,000+ | 95% | ≤2h | 50% | $4,500–$50,000 |

| AOPACK Ltd. | — | — | Fully Automatic Intelligent Packaging Systems, PLC-Controlled Stampings | $40,000+ | 100% | ≤4h | — | $50,000–$150,000 |

Performance Analysis

Shandong Yuchen and Cangzhou Ipack represent specialized manufacturers with dedicated R&D focus on automated paper processing, offering customization in material thickness, color coding, and graphic labeling. Dongguang Xinlong stands out for 100% on-time delivery and high-capacity solutions, though its lower reorder rate suggests room for improvement in long-term client retention. Cangzhou Kingsun demonstrates exceptional market traction with a 50% reorder rate and sub-2-hour responsiveness, indicating robust after-sales engagement despite mid-tier delivery consistency. AOPACK targets premium segments with fully intelligent systems priced above $50,000, suitable for integrated packaging lines requiring Industry 4.0 compatibility.

FAQs

How to verify automatic corrugated box making machine supplier reliability?

Validate certifications through official registries and request factory audit reports covering quality management systems (QMS), component sourcing, and final inspection protocols. Analyze transaction histories focusing on dispute resolution efficiency and shipment accuracy. Video tours of live production lines provide critical insight into workflow organization and equipment condition.

What is the typical lead time for standard and customized machines?

Standard models typically ship within 30–45 days after order confirmation. Custom configurations involving specialized die-cutting units, extended conveyor systems, or multi-color printing integration require 60–90 days. Rush production may reduce timelines by 10–15 days at additional cost.

Do suppliers offer customization options?

Yes, most manufacturers support adjustments in box size range, material compatibility (E/B/C-flute types), heating methods (electric/steam), and branding elements (logo engraving, color schemes). Advanced suppliers provide CAD modeling and simulation previews within 72 hours of inquiry.

What are common MOQ and pricing structures?

Minimum Order Quantity is typically 1 set. Entry-level semi-automatic systems start at $4,500, while fully integrated rotary die-cutting and gluing lines exceed $150,000. Pricing reflects automation level, control system sophistication (PLC vs. relay logic), and optional add-ons like stackers or barcode integrators.

Can suppliers handle global shipping and installation?

Established exporters manage FOB and CIF shipping globally, with sea freight recommended for full-container loads due to cost efficiency. Many offer optional technician deployment for on-site installation, calibration, and operator training, usually at an extra fee. Confirm insurance coverage and import compliance (e.g., CE marking) prior to shipment.