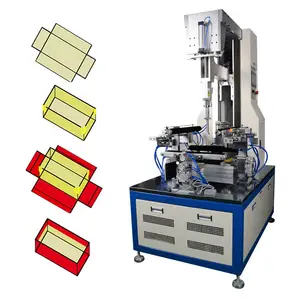

Automatic Cardboard Box Making Machine

1/12

1/12

1/6

1/6

1/26

1/26

1/14

1/14

1/17

1/17

1/16

1/16

1/16

1/16

1/22

1/22

1/20

1/20

About automatic cardboard box making machine

Where to Find Automatic Cardboard Box Making Machine Suppliers?

China remains the global epicenter for automatic cardboard box making machine manufacturing, with key production hubs concentrated in Zhejiang, Guangdong, and Hebei provinces. These regions host vertically integrated industrial clusters that combine precision engineering, sheet metal fabrication, and automation expertise. Dongguan and Ruian serve as primary centers for packaging machinery, offering mature ecosystems where component suppliers, CNC workshops, and final assembly lines operate within tight geographic proximity—reducing lead times and logistics overhead.

The sector benefits from localized supply chains for critical subsystems such as servo drives, pneumatic controls, and folding gluing units, enabling cost efficiencies of 20–35% compared to Western or Southeast Asian alternatives. Facilities typically range from 2,000 to over 20,000m², supporting batch production capacities of 10–50 units per month. Buyers gain access to scalable solutions—from compact semi-automatic models for niche food packaging to fully automated high-speed lines capable of producing 200+ boxes per minute.

How to Choose Automatic Cardboard Box Making Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm equipment specifications align with intended applications: standard models handle 3–7 ply corrugated board (E/B/C flute), while advanced systems support rigid box forming, V-grooving, and hot-melt gluing. Demand documentation on motor power (typically 3–15kW), feeding accuracy (±0.5mm), and production speed (80–250 boxes/min). For export compliance, verify CE marking and electrical safety standards (e.g., IEC 60204-1).

Production Infrastructure Assessment

Evaluate core operational indicators:

- Minimum factory area of 3,000m² for sustained volume output

- In-house design and R&D teams for customization support

- Integrated machining capabilities (laser cutting, CNC bending, welding)

Cross-reference response times (target ≤5 hours) and on-time delivery rates (ideal ≥97%) as proxies for operational reliability.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services, particularly for first-time transactions. Prioritize suppliers with verifiable online revenue histories and transparent order tracking. Conduct pre-shipment inspections via third-party auditors or video walkthroughs to validate machine functionality before dispatch. Sample testing is recommended to assess fold accuracy, glue application consistency, and material handling stability under continuous operation.

What Are the Best Automatic Cardboard Box Making Machine Suppliers?

| Company Name | Location | Main Products | Verified Type | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Dongguang Xinlong Packaging Machinery Co., Ltd. | Hebei, CN | Packaging Line, Gluing Machines, Paper Processing Machinery | - | 100% | ≤5h | $60,000+ | <15% | $15,000–$350,000 |

| Ruian Xuanhai Machine Co., Ltd. | Zhejiang, CN | Food Packaging Boxes, Disposable Cardboard Equipment | Multispecialty Supplier | 100% | ≤2h | $30,000+ | <15% | $5,000–$36,700 |

| Zhejiang Zhixin Machinery Co., Ltd. | Zhejiang, CN | Lunch Box Forming, Carton Manufacturing | Custom Manufacturer | 100% | ≤9h | - | <15% | $2,200–$35,000 |

| ZOMAGTC CO., LTD | Zhejiang, CN | Paper Processing, Bag & Box Making Machinery | - | - | ≤2h | - | - | $3,999–$18,000 |

| Wenzhou Roman Machinery Co., Ltd. | Zhejiang, CN | V-Grooving, Gift Box, Hard Cover Equipment | Multispecialty Supplier | 100% | ≤2h | $1,300,000+ | <15% | $6,333–$140,000 |

Performance Analysis

Wenzhou Roman Machinery stands out with the highest reported online revenue ($1.3M+), indicating strong market penetration and export activity, particularly in high-end gift and rigid box automation. Ruian Xuanhai and ZOMAGTC demonstrate superior responsiveness (≤2h average reply time), enhancing communication efficiency for international buyers. Dongguang Xinlong offers the widest price spectrum, including large-scale production lines exceeding $300,000, suggesting capability for turnkey packaging line integration. Notably, all verified suppliers maintain 100% on-time delivery records, though reorder rates remain below 15%, reflecting project-based purchasing patterns common in capital equipment procurement.

FAQs

What materials can automatic cardboard box machines process?

These machines typically handle single- to triple-wall corrugated paperboard (B/C/E flute), kraft paper, and food-grade cardboard. Some models support laminated board and coated stock for premium packaging applications.

What is the typical MOQ and lead time?

Minimum order quantity is generally 1 set. Lead times vary from 20–45 days depending on complexity, with additional 10–25 days for custom configurations involving PLC programming or non-standard tooling.

Can suppliers customize machine dimensions and functions?

Yes, most manufacturers offer customization for box size range, feeding system type (manual/automatic), gluing method, and control interface (touchscreen HMI with fault diagnostics). Custom tooling may require CAD submissions and mold fees.

Do these machines require certifications for import?

CE certification is commonly provided for EU and North American markets. Buyers should confirm compliance with local electrical safety and machinery directives prior to shipment to avoid customs delays.

What after-sales support should be expected?

Standard support includes installation manuals, operational videos, and remote troubleshooting. Premium suppliers offer technician dispatch services (at buyer’s cost), spare parts kits, and training sessions via video conferencing or on-site visits.