Automatic Box Making Machine

Top sponsor listing

Top sponsor listing

1/19

1/19

1/13

1/13

1/14

1/14

1/15

1/15

1/20

1/20

1/6

1/6

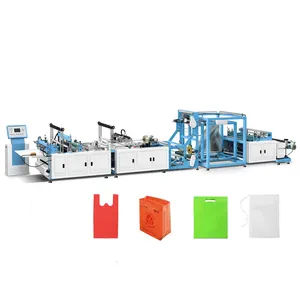

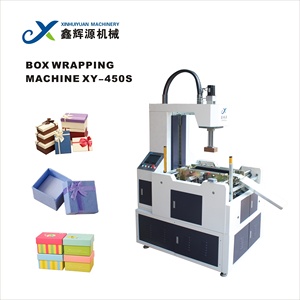

About automatic box making machine

Where to Find Automatic Box Making Machine Suppliers?

China remains the dominant hub for automatic box making machine manufacturing, with key production clusters in Shandong, Hebei, and Guangdong provinces. These regions host vertically integrated industrial ecosystems specializing in packaging machinery, supported by mature supply chains for steel components, automation systems, and paper processing equipment. Shandong’s Longkou and Dongying zones focus on heavy-duty forming machines, while Dongguan and Wenzhou specialize in precision carton and disposable packaging lines.

The clustering enables cost efficiencies through localized sourcing of motors, control systems, and molds—reducing component procurement time by 25–40%. Facilities typically integrate CNC machining, welding, assembly, and testing under one roof, supporting lead times of 30–60 days for standard configurations. Buyers benefit from scalable output, with leading suppliers capable of fulfilling bulk orders (10+ units) within eight weeks. Export-ready infrastructure ensures compatibility with international electrical standards and packaging regulations.

How to Choose Automatic Box Making Machine Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to recognized quality management systems such as ISO 9001. For markets in Europe and North America, CE marking is essential to meet safety and electromagnetic compatibility directives. Request documentation on motor efficiency ratings, PLC control systems (e.g., Mitsubishi or Siemens), and compliance with packaging industry standards like ISO 15378 for material handling integrity.

Production Capability Audits

Assess core manufacturing capacity using these benchmarks:

- Minimum factory area of 3,000m² to support dedicated assembly lines

- In-house engineering teams for customization and troubleshooting

- CNC machining, laser cutting, and robotic welding capabilities

Cross-reference on-time delivery performance (target ≥94%) and response time (ideally ≤4 hours) as indicators of operational reliability.

Customization & Support Verification

Confirm the supplier's ability to modify machine parameters including box size range, feeding system type (manual/automatic), gluing mechanism, and integration with downstream packaging lines. Evaluate after-sales support structure—prefer suppliers offering remote diagnostics, spare parts availability, and technician training programs.

What Are the Best Automatic Box Making Machine Suppliers?

| Company Name | Main Products | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization | Verification |

|---|---|---|---|---|---|---|---|

| Longkou Fushi Packing Machinery Co., Ltd. | Plastic Vacuum Forming Machines, Foam Machinery, Other Plastic Product Making Machinery | 100% | ≤6h | 20% | US $590,000+ | Limited | Custom Manufacturer |

| Dongguang Baiying Carton Machinery Co., Ltd. | Paper Product Making Machinery, Gluing Machines, Die-Cutting Machinery | 100% | ≤3h | - | - | Moderate | - |

| Dongying Besco Machine Tool Limited | Metal Box Machines, Pneumatic Punching Systems | 100% | ≤2h | 75% | US $1,800,000+ | High | Custom Manufacturer |

| Dongguan Pinchuang Automation Equipment Co., Ltd. | Rigid Box Making Machines, Case Packing, Paper Processing Machinery | 100% | ≤1h | - | US $730,000+ | High | - |

| Wenzhou Tianyue Machinery Co., Ltd. | Disposable Paper Box Machines, Sealing Systems | 94% | ≤4h | 28% | US $650,000+ | High | Multispecialty Supplier |

Performance Analysis

Dongguan Pinchuang leads in responsiveness (≤1-hour replies) and offers advanced automation for rigid box production, ideal for luxury packaging applications. Dongying Besco stands out with a 75% reorder rate, indicating strong customer satisfaction in metal junction box machinery, backed by extensive customization options including hydraulic design, material thickness adjustment, and SS304 construction. Wenzhou Tianyue focuses on high-speed food container lines with ultrasound sealing technology, catering to eco-friendly packaging demands using recycled paper substrates. Longkou Fushi provides cross-sector versatility but shows lower reorder frequency, suggesting niche application alignment. Dongguang Baiying delivers consistent performance in corrugated carton solutions with competitive pricing starting at $3,800 per unit.

FAQs

What materials can automatic box making machines process?

Standard models handle corrugated cardboard, solid bleached board, and kraft paper. Specialized variants support galvanized steel sheets, aluminum composites, and biodegradable films. Confirm tensile strength and thickness compatibility (typically 0.2–1.2mm) with the supplier prior to procurement.

What is the typical MOQ and lead time?

Most suppliers require a minimum order of 1 set. Lead times range from 30 days for standard models to 60 days for customized systems. Some manufacturers offer expedited builds for an additional 15–20% fee.

Can these machines be integrated into existing packaging lines?

Yes, particularly from suppliers like Dongguan Pinchuang and Dongying Besco, which design modular systems compatible with conveyor interfaces, barcode labeling stations, and automated stacking units. Confirm I/O signal protocols and PLC communication standards during technical review.

Do suppliers provide installation and training?

Many offer remote commissioning via video guidance. On-site support may incur extra charges. Training typically covers operation, maintenance routines, mold changeovers, and error diagnostics. Request detailed service terms before contract finalization.

Are samples available before full purchase?

Sample production is feasible—suppliers often run test runs using client-provided material specs. Sample costs are usually credited toward bulk orders. Expect 7–14 days for sample fabrication and 5–10 days for international shipping.