Automatic Rigid Box Making Machine

Top sponsor listing

Top sponsor listing

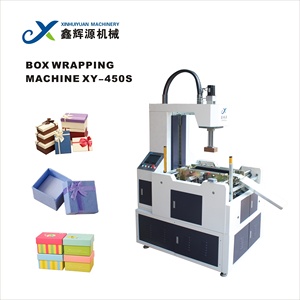

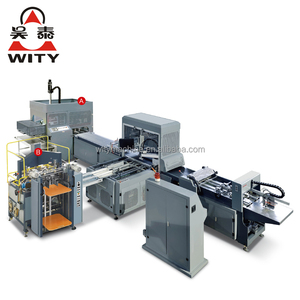

About automatic rigid box making machine

Where to Find Automatic Rigid Box Making Machine Suppliers?

China remains the global epicenter for automatic rigid box making machine manufacturing, with key production clusters concentrated in Zhejiang and Henan provinces. Wenzhou, located in Zhejiang, hosts a dense network of packaging machinery manufacturers specializing in high-precision servo-driven systems, benefiting from mature supply chains for motors, control units, and structural components. This regional specialization enables optimized production cycles and access to skilled technical labor, reducing assembly lead times by up to 25% compared to non-specialized regions.

The industrial ecosystem supports vertically integrated operations, where suppliers manage full production workflows—from CNC machining and sheet metal fabrication to final assembly and testing—within compact geographic zones. This integration enhances coordination between component suppliers and OEMs, ensuring consistent quality and faster turnaround. Buyers can expect standard lead times of 30–45 days for fully automatic models, with localized sourcing cutting logistics costs by 15–20%. The region’s focus on export-oriented manufacturing also ensures compliance with international electrical and safety standards, facilitating smoother customs clearance.

How to Choose Automatic Rigid Box Making Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to recognized quality management systems such as ISO 9001. For markets requiring regulatory alignment, confirm CE marking for electrical control panels and PLC systems. Request documentation on core component specifications, including servo motor brands (e.g., Mitsubishi, Delta), touch-screen HMI interfaces, and pneumatic system configurations.

Production Capability Audits

Assess infrastructure maturity through objective indicators:

- Facility size exceeding 2,000m² indicating capacity for batch production

- In-house engineering teams capable of customizing feed mechanisms, gluing units, and die-cut integration

- Proven experience with material adaptability (cardboard, MDF, leatherette) and variable box dimensions

Cross-reference delivery performance (target ≥98%) and response time (ideally ≤4 hours) as proxies for operational reliability.

Transaction Safeguards

Utilize secure payment frameworks that link disbursements to milestone verification. Prioritize suppliers with documented after-sales support, including remote diagnostics, spare parts availability, and technician training. Pre-shipment inspection protocols should include functional testing under load conditions to validate automation stability and dimensional accuracy.

What Are the Best Automatic Rigid Box Making Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Wenzhou Roman Machinery Co., Ltd. | Zhejiang, CN | Rigid box machines, gift box equipment | US $1.3M+ | 100% | ≤1h | <15% | Color, material, size, logo, packaging | $68,000–140,000 |

| Wenzhou Rongda Packaging Equipment Co., Ltd. | Zhejiang, CN | Fully automatic box wrappers, double-station systems | US $10,000+ | 100% | ≤4h | <15% | Size, feeder, cut settings, full automation | $21,000–180,000 |

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | Cardboard forming, phone case boxes | US $1.3M+ | 100% | ≤2h | 41% | Material, thickness, logo, graphic design | $1,930–48,571 |

| Ruian Mosun Machinery Co., Ltd. | Zhejiang, CN | Gluing, forming, pressing systems | US $200,000+ | 100% | ≤2h | <15% | Box size, gluing, air pressing, height | $8,500–15,000 |

| Shanghai Promega Trading Co., Ltd. | Shanghai, CN | Packaging & printing machinery | US $9,000+ | — | ≤6h | <15% | Material, thickness, adhesive type | Data not available |

Performance Analysis

Wenzhou-based manufacturers dominate in high-end automation, offering servo-controlled systems priced above $68,000 with proven delivery reliability (100% on-time). Wenzhou Roman and Rongda provide scalable solutions for luxury packaging producers requiring precision and consistency. In contrast, Zhengzhou Zomagtc stands out with a significantly higher reorder rate (41%), suggesting strong customer satisfaction at lower price points, though its offerings are more entry-level. Ruian Mosun delivers mid-range automation with competitive pricing and responsive communication, ideal for SMEs balancing cost and functionality. Shanghai Promega, while less active in direct machine sales, acts as a trading intermediary with limited transparency on production capacity.

FAQs

How to verify automatic rigid box machine supplier reliability?

Validate certifications (CE, ISO) through official registries. Request factory audit reports or video walkthroughs to assess production lines and quality control checkpoints. Analyze transaction history, focusing on consistent on-time delivery and post-installation support responsiveness.

What is the typical sampling timeline for customized machines?

Standard model samples take 20–35 days to produce. Custom configurations involving unique feeding systems or multi-material compatibility extend timelines to 50 days. Air freight adds 7–12 days for international delivery.

Do suppliers offer customization for box dimensions and materials?

Yes, most established suppliers support customization of length, width, height, and material thickness (typically 1–6mm cardboard or composite substrates). Advanced models allow programmable changeovers for mixed production runs.

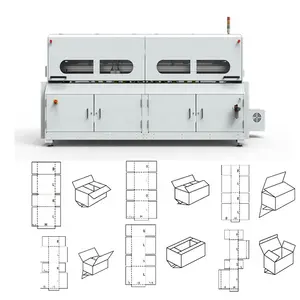

Can machines be configured for different box types?

High-end models support multiple box styles—gift boxes, shoe boxes, phone cases, and magnetic closure boxes—via software presets and modular tooling. Confirm compatibility with required box geometries before procurement.

What are common MOQ and payment terms?

MOQ is typically 1 set due to machine size and capital cost. Payment structures often include 30% deposit, 60% pre-shipment, and 10% after commissioning. Escrow services are recommended for first-time transactions.