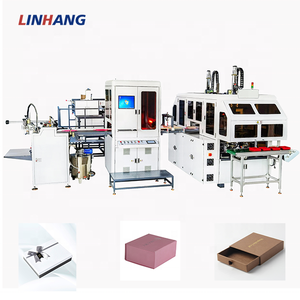

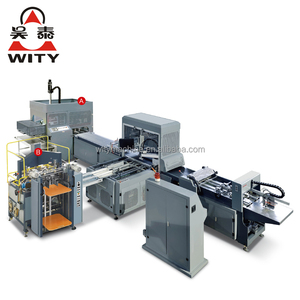

Rigid Box Making Machine

1/15

1/15

1/16

1/16

1/6

1/6

1/6

1/6

1/12

1/12

1/21

1/21

1/7

1/7

CN

CN

1/18

1/18

About rigid box making machine

Where to Find Rigid Box Making Machine Suppliers?

China remains the global epicenter for rigid box making machine manufacturing, with key industrial hubs concentrated in Guangdong, Henan, and Zhejiang provinces. These regions host vertically integrated supply chains that combine precision engineering, sheet metal fabrication, and automation expertise. Guangdong’s Pearl River Delta cluster excels in high-speed packaging machinery production, supported by advanced CNC machining networks and rapid prototyping capabilities. Meanwhile, Henan-based suppliers leverage cost-efficient logistics and access to raw materials such as steel frames, servo motors, and pneumatic systems, enabling competitive pricing without compromising structural integrity.

The ecosystem supports scalable production across semi-automatic to fully automated lines, catering to diverse applications including gift boxes, cosmetic packaging, electronics enclosures, and luxury product presentation. Manufacturers typically operate multi-functional workshops equipped with laser cutting, bending, and welding stations, allowing end-to-end development from design to final assembly. Buyers benefit from localized component sourcing, which reduces lead times to 30–45 days for standard configurations and enables flexible customization on material thickness (0.8–3.0mm), box dimensions (up to 600×400×200mm), and feeding mechanisms.

How to Choose Rigid Box Making Machine Suppliers?

Effective supplier selection requires a structured evaluation of technical, operational, and transactional parameters:

Technical Compliance & Machine Specifications

Verify adherence to international safety and performance standards such as CE or ISO 9001. Confirm machine specifications align with intended use—particularly folding accuracy, glue application control, and corner sealing consistency. For export compliance, ensure electrical components (e.g., PLCs, HMI panels) support voltage compatibility (220V/380V, 50/60Hz) and include overload protection features.

Production Capability Assessment

Evaluate critical infrastructure indicators:

- Minimum factory area of 3,000m² for stable batch output

- In-house engineering teams capable of customizing feeders, pressure settings, and mold designs

- Integration of servo-driven systems for precise corner folding and gluing

Cross-reference machine uptime data and on-time delivery records (target ≥97%) to assess reliability.

Quality Control & Transaction Security

Prioritize suppliers who conduct pre-shipment testing under load conditions and provide video demonstrations of machine operation. Utilize secure payment methods with milestone verification, especially for high-value automated systems. Request sample production runs to validate dimensional accuracy and surface finish quality before full-scale orders.

What Are the Best Rigid Box Making Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangdong huanlian Intelligent Packaging Group Co., Ltd. | Guangdong, CN | - | US $990,000+ | 100% | ≤4h | 40% | Packaging Line, Multi-Function Machines | $1,600–9,800 |

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | Custom Manufacturer | US $1,400,000+ | 100% | ≤2h | 40% | Automatic, Semi-Automatic Forming Lines | $6,442–16,370 |

| Wenzhou Rongda Packaging Equipment Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | US $10,000+ | 100% | ≤4h | <15% | Fully Automatic, Manual, Set-Up Boxes | $7,000–180,000 |

| Zhengzhou Pasen Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $250,000+ | 100% | ≤4h | 16% | Manual, V/U-Shape, Servo Corner Cutters | $700–2,100 |

| Wenzhou Roman Machinery Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | US $1,300,000+ | 100% | ≤1h | <15% | Fully Automatic, Round & Bottle Box Systems | $500–68,888 |

Performance Analysis

Guangdong huanlian and Zhengzhou Zomagtc demonstrate strong reorder rates (40%) and responsive communication, indicating consistent customer satisfaction and after-sales support. Zhengzhou Zomagtc stands out for its customization depth, offering tailored solutions in color, size, and labeling integration. Wenzhou Rongda targets premium segments with high-end fully automatic systems priced up to $180,000, though its lower reorder rate suggests room for service improvement. In contrast, Zhengzhou Pasen provides entry-level manual machines starting at $700, ideal for small workshops prioritizing affordability over throughput. Wenzhou Roman combines ultra-fast response times (≤1h) with broad technical range, including specialty round box and bottle packaging systems, making it a strategic partner for niche applications.

FAQs

How to verify rigid box making machine supplier reliability?

Validate certifications through official registries and request documented QC procedures, including weld inspections, alignment tests, and motor performance logs. Analyze transaction history for dispute resolution patterns and confirm presence of real-time monitoring during production via live video feeds.

What is the average lead time for rigid box machine orders?

Standard models ship within 20–35 days after order confirmation. Customized or fully automatic lines may require 45–60 days depending on complexity. Air freight delivers samples in 7–10 days; sea freight averages 25–35 days globally.

Do suppliers offer customization options?

Yes, most manufacturers support modifications in box size, material thickness (cardboard, grey board, chipboard), feeding method (manual, semi-auto, auto), and branding elements such as logo embossing or label placement. Custom tooling may incur additional setup fees and extended timelines.

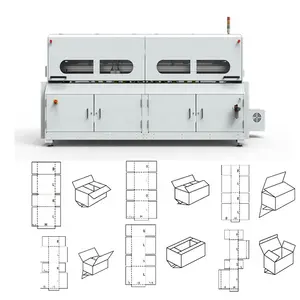

Can rigid box machines handle different box styles?

Advanced models accommodate multiple formats—including square, rectangular, cylindrical, and drawer-style boxes—via interchangeable molds and adjustable side clamps. Ensure controllers support memory presets for quick changeovers between SKUs.

What are typical MOQ and payment terms?

Most suppliers set MOQ at 1 set, facilitating pilot purchases. Payment structures commonly include 30% deposit with balance prior to shipment. Escrow services and Trade Assurance programs reduce financial risk, particularly for first-time collaborations.