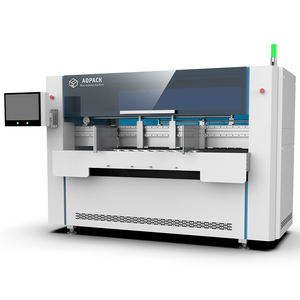

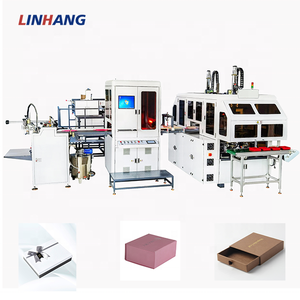

Modular Box Making Machine

CN

CN

About modular box making machine

Where to Find Modular Box Making Machine Suppliers?

China remains the global hub for modular box making machine manufacturing, with key production clusters in Guangdong, Zhejiang, and Hebei provinces. These regions host vertically integrated supply chains that combine precision engineering, sheet metal fabrication, and automation expertise. Dongguan and Ruian have emerged as specialized centers, offering concentrated access to CNC machining facilities, servo-driven control systems, and packaging line integration specialists.

The industrial ecosystems in these zones support rapid prototyping and scalable production, with many suppliers operating end-to-end manufacturing processes—from raw material processing to final assembly—within single facilities. This integration reduces component lead times by up to 40% compared to fragmented production models. Buyers benefit from average delivery cycles of 30–50 days for standard configurations, with localized sourcing of motors, pneumatics, and control panels contributing to a 15–25% cost advantage over Western-built equivalents.

How to Choose Modular Box Making Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Confirm adherence to international safety and quality benchmarks. ISO 9001 certification should be considered a baseline requirement for process consistency. For export markets in Europe and North America, CE marking is essential for regulatory compliance and customs clearance. Request documentation on electrical system conformity (IEC standards) and mechanical safety (EN 1037/EN 60204-1).

Production Capability Assessment

Evaluate supplier infrastructure using these criteria:

- Minimum factory area exceeding 3,000m² to ensure dedicated production lines

- In-house engineering teams capable of CNC programming, mechanical design, and PLC integration

- On-site testing protocols for punch alignment, forming accuracy, and cycle speed validation

Cross-reference claimed capabilities with verified performance metrics such as on-time delivery rates (>97%) and response efficiency (≤5 hours).

Customization & Quality Assurance

Assess flexibility in handling material types (steel, aluminum, cardboard), dimensional ranges, and finishing requirements. Suppliers should offer configurable tooling setups for different box geometries and pressing forces. Prioritize those providing real-time monitoring via HMI interfaces and fault diagnostics. Verify QC procedures including pre-shipment run tests, dimensional inspection reports, and load endurance trials.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate risk during initial procurement. Analyze order history and reorder rates—suppliers with sustained customer return rates indicate product reliability and after-sales support effectiveness. Conduct sample testing to validate forming precision, structural integrity, and operational stability before full-scale ordering.

What Are the Best Modular Box Making Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate |

|---|---|---|---|---|---|---|

| Dongguan Qiaosen Machinery Co., Ltd. | Guangdong, CN | Metal Straightening Machinery (455), Punching Machines (378) | US $10,000+ | 100.0% | ≤3h | <15% |

| Hebei Lincheng Packaging Machinery Manufacturing Co., Ltd. | Hebei, CN | Corrugated Box Lines, Carton Forming Systems | Data not available | 100.0% | ≤5h | Not reported |

| Ruian Mosun Machinery Co., Ltd. | Zhejiang, CN | Corrugated Box Machines, V-Grooving Equipment | US $200,000+ | 100.0% | ≤2h | <15% |

| Ruian Xuanhai Machine Co., Ltd. | Zhejiang, CN | Paper Box Machines, Food Container Lines | US $30,000+ | 100.0% | ≤2h | <15% |

| Zhejiang Chinaworld Machinery Co., Ltd. | Zhejiang, CN | Paper Product Machinery (105), Bag Makers | Data not available | 100.0% | ≤10h | Not reported |

Performance Analysis

Dongguan Qiaosen and Ruian Mosun demonstrate strong technical specialization, supported by high online revenue and fast response times. Mosun stands out with extensive customization options for box size, gluing parameters, and material feed width. Hebei Lincheng focuses on large-scale corrugated lines, evidenced by multimillion-dollar system offerings, though limited reorder data suggests primarily project-based sales. Zhejiang-based suppliers like Xuanhai and Chinaworld target mid-tier food packaging applications with competitive pricing ($3,300–$15,000 range). All listed suppliers maintain perfect on-time delivery records, indicating robust production planning, but only Mosun and Qiaosen disclose comprehensive equipment portfolios, enabling better capability assessment.

FAQs

What materials can modular box making machines process?

These machines handle a range of substrates including galvanized steel, aluminum coil, corrugated cardboard, and rigid paperboard. Processing thickness typically ranges from 0.3mm to 3.0mm depending on press tonnage and drive configuration. High-speed electric models are optimized for thin-gauge metal forming, while hydraulic variants suit heavy-duty applications.

What is the typical MOQ and lead time?

Minimum Order Quantity is generally 1 set or case. Lead times vary from 30 to 50 days based on complexity—standard semi-automatic models ship within 30 days, while fully automated or custom-configured lines may require 45–60 days for completion and testing.

Do suppliers offer customization options?

Yes, most suppliers provide tailored solutions for box dimensions, pressing force, automation level, and feeding mechanisms. Customization extends to color coding, logo embossing, labeling integration, and packaging configurations. Engineering teams typically require technical drawings or sample units to finalize modifications.

Can machines be integrated into existing production lines?

Modular designs facilitate integration with upstream feeders, stacking systems, and downstream conveyors. Suppliers with CNC and PLC development capabilities can synchronize machine I/O signals with central control systems using common protocols (e.g., Modbus, Profibus). Confirm interface compatibility prior to procurement.

How to verify machine performance before purchase?

Request live video demonstrations or factory visits to observe running units. Obtain test samples produced under your specified parameters. Review machine specifications including stroke rate (SPM), motor power (kW), air pressure requirements (bar), and dimensional tolerances (±0.1–0.3mm). Third-party inspection services can conduct pre-shipment audits for critical orders.