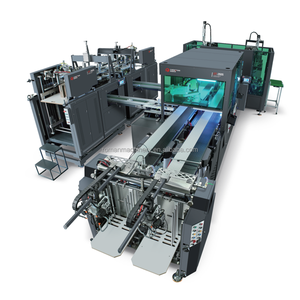

Automatic Box Maker

CN

CN

About automatic box maker

Where to Find Automatic Box Maker Suppliers?

China remains the global epicenter for automatic box maker manufacturing, with key production clusters in Zhejiang, Hebei, and Guangdong provinces. These regions host vertically integrated facilities specializing in packaging machinery, supported by mature supply chains for servo motors, PLC control systems, and precision sheet metal components. Wenzhou and Cangzhou have emerged as hubs for rigid and corrugated box automation equipment, offering scalable production lines capable of handling paperboard thicknesses from 1mm to 6mm.

The industrial ecosystem enables rapid prototyping and volume scaling, with many suppliers operating end-to-end production floors exceeding 5,000m². Buyers benefit from localized access to CNC machining, laser cutting, and robotic assembly units, reducing component lead times by 20–30% compared to offshore alternatives. Average delivery cycles range from 30 to 45 days for standard models, while customized configurations may require 60 days. The concentration of engineering talent and modular design platforms allows for flexible output adjustments, supporting both low-volume niche applications and high-speed industrial deployments.

How to Choose Automatic Box Maker Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Verify adherence to international quality standards such as ISO 9001 for quality management systems. For exports to Europe or North America, CE marking is essential to ensure compliance with safety, health, and environmental regulations. Request documentation on electrical control systems (e.g., Siemens or Mitsubishi PLCs), motor efficiency ratings, and mechanical safety interlocks. Confirm that machines undergo factory acceptance testing (FAT) before shipment.

Production Capacity Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum factory area of 3,000m² to support dedicated assembly lines

- In-house R&D capability focused on motion control, folding mechanisms, and gluing precision

- Integration of CNC fabrication and welding stations for structural frame production

Cross-reference declared on-time delivery performance (target ≥98%) with order history data where available.

Customization and Quality Control

Prioritize suppliers offering configurable parameters including box dimensions (L×W×H), material compatibility (kraft paper, grey board, corrugated cardboard), and production speed (up to 120 boxes/minute). Confirm availability of pre-shipment inspection protocols and third-party quality audits. Reorder rate—where disclosed—serves as an indicator of post-sale satisfaction and machine reliability.

What Are the Best Automatic Box Maker Suppliers?

| Company Name | Main Products | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| AOPACK Ltd. | Automatic Corrugated Carton Box Machines | $50,000–150,000 | 1 piece | 100% | ≤4h | - | US $40,000+ | No |

| Ruian Koten Machinery Co., Ltd. | Rigid & Cake Box Makers | $12,500–129,000 | 1 set | 100% | ≤4h | <15% | US $2,000+ | Yes |

| Wenzhou Roman Machinery Co., Ltd. | Fully Automatic Rigid Box Makers | $6,000–148,000 | 1 set/unit | 100% | ≤1h | <15% | US $1,300,000+ | Yes |

| Cangzhou Jialong Packaging Machinery Co., Ltd. | Corrugated Carton & Partition Assemblers | $2,500–198,000 | 1 set | 100% | ≤3h | 66% | US $1,000,000+ | Yes |

| Dongguang Baiying Carton Machinery Co., Ltd. | Pizza & Corrugated Box Makers | $4,000–80,000 | 1 piece | 100% | ≤3h | - | - | No |

Performance Analysis

Cangzhou Jialong stands out with a 66% reorder rate, indicating strong customer retention likely driven by consistent machine uptime and after-sales service. Wenzhou Roman leads in responsiveness, answering inquiries within one hour, which enhances communication efficiency during technical validation phases. AOPACK and Dongguang Baiying focus on standardized models with no listed customization, making them suitable for buyers seeking turnkey solutions. In contrast, Ruian Koten and Wenzhou Roman offer extensive configurability in size, material, and branding integration, ideal for specialty packaging producers. Suppliers with higher online revenue (e.g., >US $1M annually) typically maintain larger inventories and more robust technical teams, enabling faster project execution.

FAQs

How to verify automatic box maker supplier reliability?

Cross-check ISO and CE certifications through official registries. Request factory audit reports or video walkthroughs to validate production processes. Analyze buyer feedback focusing on machine durability, after-sales support, and accuracy in dimensional tolerances (±0.5mm typical).

What is the typical sampling timeline for automatic box makers?

Standard model demonstrations can be arranged within 15–20 days. Customized units require 30–45 days for prototype completion, depending on complexity. Air freight shipping adds 7–10 days internationally.

Can suppliers handle global shipping and installation?

Most established manufacturers offer FOB or CIF shipping terms and coordinate sea freight logistics. Some provide optional on-site installation and operator training, particularly for machines above $50,000. Confirm inclusion of technical manuals, spare parts kits, and electrical compatibility (380V/50Hz standard).

Do suppliers offer free samples or trial runs?

Free physical samples are uncommon due to machine scale. However, many suppliers conduct live video trials using customer-specified materials. Sample fees may be waived upon confirmation of full orders, especially for purchases exceeding one unit.

How to initiate customization requests for box makers?

Submit detailed specifications including target box dimensions, feedstock type (e.g., single-wall corrugated, rigid board), desired output speed (boxes/hour), and integration requirements (conveyor interface, glue system type). Leading suppliers respond with CAD layouts and process flow diagrams within 72 hours.