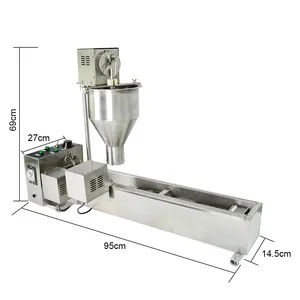

Automatic Doughnut Maker

1/28

1/28

1/21

1/21

1/25

1/25

1/15

1/15

1/18

1/18

1/10

1/10

1/17

1/17

1/6

1/6

1/2

1/2

About automatic doughnut maker

Where to Find Automatic Doughnut Maker Suppliers?

China remains the central hub for automatic doughnut maker manufacturing, with key production clusters in Guangdong and Henan provinces. These regions host vertically integrated facilities specializing in commercial snack machinery, supported by mature supply chains for stainless steel, heating elements, and automated control systems. Guangzhou-based suppliers dominate export activity, leveraging proximity to major ports for efficient global distribution, while Luohe and Anyang in Henan offer cost advantages due to lower labor and operational expenses.

The industrial ecosystem enables streamlined production from design to assembly, with many manufacturers operating in-house CNC machining, welding, and electrical integration units. This localization reduces component lead times and supports rapid prototyping. Buyers benefit from scalable output—standard models are typically available within 15–30 days—with some suppliers reporting monthly production capacities exceeding 200 units. The concentration of technical expertise and ancillary service providers within 50km radii ensures consistent quality control and logistical efficiency across bulk orders.

How to Choose Automatic Doughnut Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure reliability and product compliance:

Technical Specifications & Compliance

Confirm adherence to international safety standards such as CE or UL, particularly for electrical components and food-contact materials. Stainless steel construction (preferably grade 304) is standard across commercial-grade units. Verify temperature control accuracy, oil filtration systems, and automation level—fully automatic models integrate dough dispensing, frying, flipping, and ejection processes.

Production Capacity Verification

Assess supplier infrastructure through documented metrics:

- Minimum factory area of 3,000m² indicating scale of operations

- In-house engineering teams capable of customization (e.g., output rate adjustments, voltage configurations)

- Monthly production capacity exceeding 100 units for high-volume buyers

Cross-reference on-time delivery rates (target ≥97%) and response times (≤2 hours preferred) as indicators of operational efficiency.

Transaction Security & Quality Assurance

Prioritize suppliers offering third-party inspection options prior to shipment. Analyze reorder rates as a proxy for customer satisfaction—rates above 30% suggest strong post-sale performance. Request sample testing to evaluate fry consistency, cycle time accuracy, and ease of cleaning. For customized units, confirm availability of CAD drawings and functional prototypes within 7–10 days.

What Are the Best Automatic Doughnut Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Longterm Kitchen Equipment Co., Ltd. | Guangdong, CN | Automatic Mini Donut Machines, Fryers | US $310,000+ | 94% | ≤6h | 33% | $260–635 | 1 piece/carton |

| Anyang Toko Machinery Co., Ltd. | Henan, CN | Mini Donut Makers, Mochi Donut Machines | US $120,000+ | 100% | ≤1h | 31% | $790–1,680 | 1 set |

| Luohe Bard Machinery Equipment Co., Ltd. | Henan, CN | Commercial 4-Row Donut Makers | US $50,000+ | 97% | ≤2h | <15% | $534–846 | 1–2 sets |

| Guangzhou Goodloog Kitchen Equipment Co., Ltd. | Guangdong, CN | Heavy-Duty Snack Machines, Donut Fryers | US $40,000+ | 100% | ≤2h | 15% | $730–1,650 | 1 unit/set |

| Guangzhou New Power Catering Equipment Manufacturing Co., Ltd. | Guangdong, CN | Stainless Steel Snack Makers, Mini Donut Machines | US $40,000+ | 100% | ≤2h | <15% | $606–1,310 | 1 set |

Performance Analysis

Guangzhou Longterm stands out for competitive pricing and high reorder volume, indicating robust market acceptance despite a longer average response time. Anyang Toko combines perfect on-time delivery with sub-hour responsiveness, positioning it as a top-tier option for time-sensitive procurement. Henan-based manufacturers offer mid-range pricing with reliable throughput, while Guangdong suppliers provide broader product variety and higher-end builds. Buyers seeking low MOQs can leverage Guangzhou Longterm’s carton-based ordering, whereas large-scale operators may prioritize Anyang Toko’s 960 pcs/hour capacity models. All listed suppliers utilize 304 stainless steel frames and PLC-controlled automation, ensuring baseline durability and operational consistency.

FAQs

How to verify automatic doughnut maker supplier reliability?

Validate certifications (CE, ISO 9001) through official registries and request test reports for electrical safety and thermal performance. Review transaction history, focusing on on-time delivery consistency and post-purchase support. Conduct video audits of production lines to confirm in-house manufacturing capabilities.

What is the typical lead time for automatic doughnut makers?

Standard units ship within 15–25 days after order confirmation. Custom configurations, including voltage adaptation (110V/220V) or output scaling, may extend lead times to 35–45 days. Air freight delivers samples in 7–10 days; sea freight takes 25–35 days depending on destination.

Can suppliers accommodate customization requests?

Yes, most suppliers support modifications such as production speed adjustment, compact footprint designs, and bilingual control panels. Guangzhou Longterm explicitly lists size customization options. Submit detailed technical requirements—including desired output per hour, power supply, and dimensional constraints—for accurate quoting and feasibility assessment.

What are common MOQs for automatic doughnut makers?

MOQs range from 1 piece (for component-level orders) to 1 set (complete machine). Some suppliers offer flexible terms at 1–2 sets, enabling small businesses to test market demand before scaling. Bulk discounts typically apply at 5+ units.

Do suppliers provide samples for evaluation?

Sample availability varies. Some manufacturers offer pre-production units for testing at full price, which may be credited toward future bulk orders. Free samples are rare but negotiable for high-volume commitments. Always specify required functionality (e.g., continuous operation over 8 hours) when requesting evaluation units.