Automatic Momo Making Machine Producer

About automatic momo making machine producer

Where to Find Automatic Momo Making Machine Producers?

China leads global production of automatic momo making machines, with concentrated manufacturing hubs in Henan and Shandong provinces. These regions host specialized food machinery clusters integrating component suppliers, engineering teams, and logistics networks within compact industrial zones. Henan’s Zhengzhou and Xinxiang areas are home to over 70% of commercial-grade grain product equipment manufacturers, offering scalable production capacity and rapid prototyping capabilities. Shandong’s Qingdao and Jining zones emphasize stainless steel fabrication and automated assembly lines, leveraging proximity to raw material sources to reduce structural costs by 15–25% compared to non-integrated suppliers.

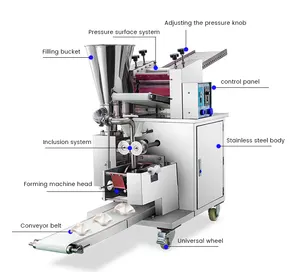

The regional ecosystems support both standardized and custom-built machines, with average facility sizes exceeding 3,000m² and monthly production outputs ranging from 100 to 500 units per supplier. Buyers benefit from streamlined sourcing through vertically integrated supply chains—where dough pressing mechanisms, filling systems, and molding components are produced in-house—reducing lead times to 20–40 days for bulk orders. Localized testing centers enable performance validation under real-world conditions, ensuring consistent output quality across batches.

How to Choose Automatic Momo Making Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify adherence to international electrical and mechanical safety standards. Machines operating at 110V/220V must comply with IEC 60204-1 for industrial machinery safety. Stainless steel components should meet ASTM A240 or equivalent corrosion resistance benchmarks. While formal certifications (ISO 9001, CE) are not universally declared in available data, prioritize suppliers who provide test reports for motor efficiency, filling accuracy, and cycle durability.

Production Capacity Verification

Assess infrastructure maturity using key indicators:

- Facility area ≥3,000m² indicating volume production capability

- In-house R&D or customization teams supporting design modifications

- Integrated manufacturing processes including CNC machining, welding, and final assembly

Cross-reference online revenue metrics (where available) with on-time delivery rates—suppliers reporting US $100,000+ annual digital sales typically maintain delivery performance above 90%.

Procurement Safeguards

Utilize secure payment frameworks such as escrow services until post-delivery inspection is completed. Evaluate response time consistency (≤3 hours is standard; ≤1 hour indicates high service priority). Confirm reorder rates as a proxy for customer satisfaction—rates above 15% suggest reliable machine performance and after-sales support. Request sample units to validate forming speed, sealing integrity, and ease of cleaning before full-scale procurement.

What Are the Best Automatic Momo Making Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Support | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Xuzhong Food Machinery Co., Ltd. | Guangdong, CN | Dough mixer, stuffing mixer, baozi/momo machine | US $200,000+ | 91% | ≤4h | 15% | Yes (material, size, capacity, logo) | $1,799–$17,798 |

| Saidashi Machinery (Henan) Co., Ltd. | Henan, CN | Momo machine, vegetable cutter, meat processor | US $100,000+ | 100% | ≤3h | 19% | Limited | $499–$1,209 |

| Henan Qiansheng Machinery Co., Ltd. | Henan, CN | Automatic baozi/momo maker, shaomai molder | US $90,000+ | 100% | ≤1h | <15% | Yes (color, size, packaging, graphics) | $1,250–$5,800 |

| Shandong Meiying Food Machinery Co., Ltd. | Shandong, CN | Dough sheeter, baking oven, noodle/momo machine | US $2,000+ | 50% | ≤3h | <15% | No | $580–$850 |

| Chanda Machine CoLtd | Henan, CN | Filling machines, meat slicer, momo maker | Data Unavailable | Data Unavailable | ≤3h | Data Unavailable | Limited | $660–$1,850 |

Performance Analysis

Guangzhou Xuzhong stands out for high customization depth and extensive product integration, though its 91% on-time delivery rate suggests moderate logistical risk. Saidashi Machinery demonstrates strong reliability with 100% on-time fulfillment and the highest reorder rate (19%), indicating market confidence in machine durability. Henan Qiansheng excels in responsiveness (≤1h average) and offers comprehensive customization, ideal for buyers requiring branded or region-specific configurations. Shandong Meiying provides entry-level pricing but shows lower delivery consistency (50%), which may impact time-sensitive deployments. Chanda Machine lacks verifiable performance metrics, increasing due diligence requirements for potential partners.

FAQs

How to verify automatic momo making machine supplier reliability?

Cross-check declared revenue and delivery rates with third-party trade verification services. Request factory audit videos focusing on assembly line operations and quality control checkpoints. Analyze customer reviews for recurring themes around machine uptime, spare parts availability, and technical support responsiveness.

What is the typical MOQ and lead time?

Minimum order quantity is typically 1 set across all major suppliers. Lead times range from 15 to 30 days for standard models; customized units may require 35–50 days depending on complexity. Expedited production is available from select manufacturers upon negotiation.

Do suppliers offer customization options?

Yes, leading producers support modifications in material (stainless steel grade), capacity (output per hour), voltage (110V/220V), color, and branding (logo, panel graphics). Full technical specifications must be submitted prior to engineering review.

Can machines be tested before shipment?

Reputable suppliers conduct pre-shipment testing and provide video demonstrations of machine operation, including dough feeding, filling metering, and sealing cycles. On-site inspections can be arranged through third-party agencies like SGS or Bureau Veritas.

What are common packaging and export practices?

Machines are typically crated in seaworthy wooden cases with moisture barriers and shock-absorbing materials. Export documentation includes packing lists, commercial invoices, and bill of lading. Most suppliers support FOB, CIF, and DDP shipping terms with Incoterms® 2020 compliance.