Manual Machine Producer

Top sponsor listing

Top sponsor listing

1/27

1/27

1/25

1/25

1/19

1/19

1/19

1/19

1/10

1/10

1/15

1/15

1/28

1/28

1/24

1/24

1/18

1/18

About manual machine producer

Where to Find Manual Machine Producers?

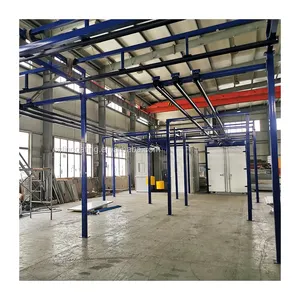

China remains the global epicenter for manual machine production, with key manufacturing clusters in Shanghai, Yangzhou, Hebei, Fujian, and Henan provinces. These regions host vertically integrated facilities that combine design, fabrication, and assembly under one roof, enabling efficient production of semi-automatic and manual industrial systems. Shanghai and Hebei lead in coating and painting line machinery, leveraging proximity to steel and automotive sectors, while Fujian specializes in paper processing equipment supported by regional raw material availability.

The concentration of suppliers in these zones allows for optimized supply chains—component sourcing, machining, and logistics are typically managed within 50–100 km radii. This integration reduces lead times to 30–45 days for standard configurations and supports cost advantages of 20–30% compared to Western manufacturers. Buyers benefit from scalable output, with established producers capable of fulfilling bulk orders while maintaining flexibility for customized modifications in voltage, configuration, and automation level.

How to Choose Manual Machine Producers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to international quality standards such as ISO 9001. For exports to regulated markets, verify CE marking where applicable, particularly for electrical components and machinery safety. Request documentation on material sourcing, welding integrity, and control system specifications to ensure compliance with destination-country regulations.

Production Capability Assessment

Evaluate core infrastructure indicators:

- Facility size exceeding 3,000m² for sustained volume output

- In-house engineering teams supporting custom design and prototyping

- Integrated production lines covering cutting, bending, conveyor systems, and surface treatment

Cross-reference on-time delivery performance (target ≥95%) and response time (ideally ≤3 hours) as proxies for operational efficiency.

Transaction Risk Mitigation

Utilize secure payment mechanisms tied to delivery milestones. Prioritize suppliers with proven reorder rates above 25%, indicating customer satisfaction and product reliability. Conduct pre-shipment inspections or request factory audit reports to validate quality control processes. Sampling is strongly advised—benchmark machine durability, coating uniformity, and operational stability before full-scale procurement.

What Are the Best Manual Machine Producers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Verified Manufacturer |

|---|---|---|---|---|---|---|---|

| Shanghai Seny Machinery Co., Ltd. | Food Processing Lines, Snack & Biscuit Machines | Color, material, shape, size, logo, packaging, electrical config | 100% | ≤3h | 60% | US $970,000+ | Yes |

| Fujian Xinyun Machinery Development Co., Ltd. | Paper Making & Processing Machinery | Labeling, packaging, sealing, non-woven fabric handling | 100% | ≤2h | <15% | US $900,000+ | No |

| Hebei Hanna Technology Co., Ltd. | Liquid & Powder Coating Lines, Painting Equipment | Conveyor, color, material, pretreatment, design, logo | 100% | ≤5h | <15% | US $660,000+ | No |

| Henan Xuanhua Imp.& Exp. Trading Co., Ltd. | Rebar Cutting & Bending Machines, Spare Parts Lines | Diameter, material, rebar type, machine configuration | 95% | ≤2h | 25% | US $600,000+ | Yes |

| Yangzhou Ours Machinery Co., Ltd. | Metal Coating Machinery, Electrostatic Spray Systems | Line layout, spray gun placement, curing oven setup | 100% | ≤4h | <15% | US $3,000+ | No |

Performance Analysis

Shanghai Seny Machinery stands out with a 60% reorder rate and verified manufacturing status, reflecting strong customer retention and vertical integration. Fujian Xinyun offers competitive pricing in the paper machinery segment with rapid ≤2-hour responses but lower repeat order volume. Hebei Hanna and Yangzhou Ours specialize in coating systems with full-line capabilities, though both report reorder rates below 15%, suggesting limited aftermarket engagement. Henan Xuanhua, while showing a 95% on-time rate, provides high customization for construction equipment at accessible price points starting under $1,000 per unit. Buyers seeking long-term partnerships should prioritize suppliers with documented production lines and engineering support, confirmed via facility tours or process videos.

FAQs

How to verify a manual machine producer’s credibility?

Validate certifications through official registries and request third-party audit summaries. Analyze transaction history, focusing on consistent on-time delivery and response speed. Direct communication with past buyers or inspection agents can further confirm reliability.

What is the typical minimum order quantity (MOQ)?

Most suppliers require an MOQ of 1 set for machinery, allowing buyers to test performance before scaling. Some may offer partial container loads for multi-unit trials.

What customization options are commonly available?

Producers routinely adjust machine dimensions, materials, power requirements (110V/220V/380V), control panels, conveyor speeds, and branding elements. Full line layouts can be adapted for space-constrained facilities or specific workflow sequences.

What are average lead times for production and shipping?

Standard production lead time ranges from 30 to 45 days after deposit confirmation. Air freight takes 5–10 days for critical components; sea freight requires 20–35 days depending on destination port and customs procedures.

Do suppliers provide technical support and installation guidance?

Many offer remote support via video or manuals. Some include on-site commissioning services at additional cost. Confirm service scope and language proficiency (English-speaking technicians) prior to order finalization.