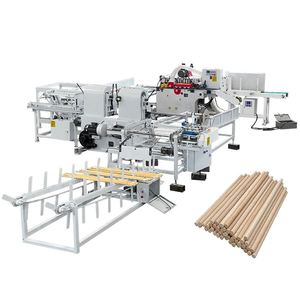

Automatic Mop Making Machine

CN

CN

About automatic mop making machine

Where to Find Automatic Mop Making Machine Suppliers?

China remains the global epicenter for automatic mop making machine production, with key manufacturing clusters in Zhejiang, Henan, and Guangdong provinces. These regions host vertically integrated supply chains that support both high-volume output and specialized automation solutions. Zhejiang-based suppliers leverage proximity to Shanghai’s logistics network, enabling faster export processing and reduced shipping costs. Meanwhile, manufacturers in Henan benefit from lower labor and operational expenses, translating into competitive pricing for large-scale industrial systems.

The sector is characterized by a dual-tier supplier base: one focused on consumer-grade robotic mopping units and another specializing in heavy-duty industrial machinery for commercial mop fabrication. Industrial producers typically operate automated assembly lines capable of producing complete machines or components such as extrusion units, cutting modules, and ultrasonic welding stations. Buyers gain access to scalable production ecosystems where raw material sourcing, CNC machining, and final testing occur within tightly coordinated networks—often within 50km radii—supporting lead times averaging 30–60 days depending on customization level.

How to Choose Automatic Mop Making Machine Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international quality standards such as ISO 9001. For suppliers offering electric or motorized equipment, CE, RoHS, or UL certification indicates compliance with electrical safety and environmental regulations required in North American and European markets. Request documentation for component-level testing, particularly for motors, control panels, and structural integrity under continuous operation.

Production Capability Assessment

Evaluate core manufacturing infrastructure using these benchmarks:

- Minimum factory area exceeding 2,000m² for industrial equipment producers

- In-house engineering teams supporting custom design and automation integration

- CNC machining, laser cutting, and welding capabilities to ensure precision assembly

Cross-reference listed product ranges with actual production scope. A high number of active listings in robot vacuums or smart mops may indicate stronger expertise in consumer automation rather than industrial machinery.

Order Flexibility and Transaction Reliability

Analyze minimum order quantities (MOQs) and pricing structures. Industrial-grade automatic mop making machines often require MOQs of 1 set at prices ranging from $1,000 to over $200,000, reflecting system complexity. In contrast, suppliers marketing "automatic mop" products may offer lower-priced units ($3.90–$300) intended for end-use rather than manufacturing. Prioritize suppliers with verifiable on-time delivery rates above 90%, response times under 8 hours, and transparent reorder metrics indicating customer retention.

What Are the Best Automatic Mop Making Machine Suppliers?

| Company Name | Main Products (Listings) | Price Range (USD) | Min. Order | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Spair (Hangzhou) Technology Co., Ltd. | Robot Vacuums (245), Wet Dry Vacuum Cleaner (64) | $170–320 | 10–1,000 pieces | 90% | ≤4h | 15% | $210,000+ | Not specified |

| Sharetronic Data Technology Co., Ltd. | Robot Vacuums (236), Network Camera (15) | $89.90–288 | 1–1,000 pieces | 81% | ≤8h | <15% | $20,000+ | Not specified |

| KAIFENG JASUN INDUSTRY INC | Soap Making Machines (140,670), Mixing Equipment (1,217) | $1,000–10,000 | 1 set | - | ≤1h | - | - | Not specified |

| Changshu Hongyi Nonwoven Machinery Co., Ltd. | Nonwoven Machinery (Industrial Scale) | $6,000–200,000 | 1 set | 100% | ≤5h | - | $500+ | Color, roller width, machine type, weight, packaging, label, dimensions, power specs |

| Bazhou Yiyang Household Products Co., Ltd. | Mops (717), Smart Mops (18) | $3.92–6.50 | 1–1,000 pieces | 95% | ≤1h | 29% | $600,000+ | Not specified |

Performance Analysis

Suppliers like Changshu Hongyi stand out for industrial capability, offering full-scale nonwoven fiber processing lines with extensive customization options and a verified 100% on-time delivery rate. Their systems target high-capacity production environments, with pricing reflecting robust build quality and long-term durability. KAIFENG JASUN, while listing automatic mop making machines, primarily operates in chemical and soap manufacturing equipment—indicating potential cross-sector applicability but requiring due diligence on domain-specific expertise.

Consumer-focused suppliers such as Bazhou Yiyang dominate in volume sales of ready-to-use mops, supported by strong reorder performance (29%) and rapid responsiveness. However, their offerings are generally not industrial machines but finished mop products marketed as “automatic,” which can create confusion during procurement. Spair and Sharetronic position themselves in smart cleaning devices, suggesting stronger competency in robotics and electronics rather than mechanical manufacturing systems.

FAQs

How to verify automatic mop making machine supplier reliability?

Cross-check ISO certifications with issuing bodies and request factory audit reports or video walkthroughs. Assess technical capacity through product specifications, material sourcing transparency, and after-sales service policies. Prioritize suppliers with documented quality control processes and third-party transaction validation.

What is the typical lead time for automatic mop making machines?

Standard models ship within 30–45 days after order confirmation. Custom-built industrial systems may require 60–90 days, depending on complexity. Allow additional time for international shipping via sea freight (20–35 days) or air cargo (5–10 days).

Can suppliers provide OEM/ODM services?

Yes, many suppliers offer OEM labeling and design modifications. Changshu Hongyi explicitly lists customization parameters including color, roller diameter, effective width, heating power, and branding. Confirm tooling costs, NDA protections, and prototype approval timelines before engagement.

Are samples available before bulk ordering?

Sample availability varies. Some suppliers offer functional prototypes or demonstration units for industrial machines at partial cost recovery. For consumer-style automatic mops, single-unit purchases are common. Clarify whether sample fees are refundable against future orders.

What are common payment terms for industrial machines?

Standard terms include 30% advance payment via T/T, with balance due before shipment. For high-value systems, consider using escrow services or Trade Assurance programs to mitigate risk. LC payments are accepted by established exporters with export licenses.