Automatic Namkeen Machine

About automatic namkeen machine

Where to Find Automatic Namkeen Machine Suppliers?

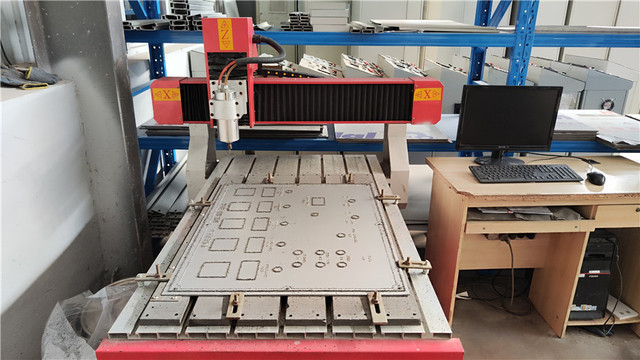

China leads global manufacturing of automatic namkeen machinery, with key production clusters in Guangdong, Liaoning, and Henan provinces. These regions host vertically integrated facilities specializing in food processing automation, enabling cost-efficient production and rapid scalability. Foshan (Guangdong) and Dalian (Liaoning) serve as primary hubs for export-oriented manufacturers, combining advanced CNC fabrication with proximity to major ports like Shenzhen and Dalian, reducing logistics lead times by 10–15% compared to inland counterparts.

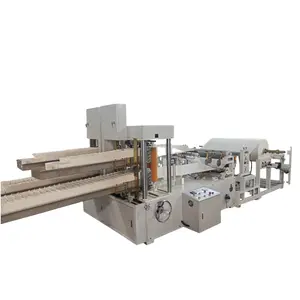

Suppliers in these clusters offer diverse configurations—from compact semi-automatic units for small businesses to fully automated lines capable of 200+ pcs/min output. The ecosystem supports end-to-end sourcing, with component suppliers for servo motors, stainless steel forming systems, and PLC controls operating within close geographic proximity. This integration enables standard lead times of 25–40 days for customized orders and economies of scale that reduce unit costs by 20–30% versus non-specialized manufacturers.

How to Choose Automatic Namkeen Machine Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international safety and quality benchmarks. CE marking is essential for European market compliance, while ISO 9001 certification indicates standardized quality management. Confirm machine specifications include food-grade stainless steel (SS304 or equivalent), overload protection systems, and programmable logic controllers (PLCs) from recognized brands (e.g., Siemens, Mitsubishi).

Production Capability Assessment

Evaluate supplier infrastructure using the following criteria:

- Minimum factory area of 3,000m² for full-line assembly capacity

- In-house engineering teams supporting customization (e.g., mold design, printing integration)

- On-time delivery performance exceeding 90% (verified via transaction history)

- Reorder rate above 40% as an indicator of customer satisfaction and product reliability

Cross-reference digital facility tours or video audits with documented production workflows to validate claims about automation level and process control.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as third-party escrow until post-delivery inspection. Prioritize suppliers with transparent revenue reporting (e.g., >US$1M annual online turnover) and response times under 3 hours, indicating robust customer service infrastructure. Request sample testing under real operating conditions to assess consistency in product shaping, oil drainage efficiency, and cycle timing accuracy.

What Are the Best Automatic Namkeen Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Dalian Jori Co., Ltd. | Liaoning, CN | Food Processing Lines (493) | US $1,900,000+ | 100% | ≤2h | 68% | $5,000–30,000 | 1 unit |

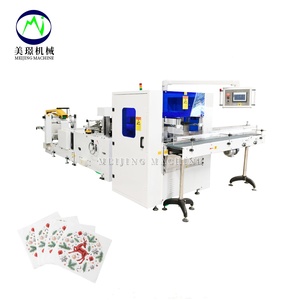

| Foshan Nanhai Meijing Machinery Manufacture Co., Ltd. | Guangdong, CN | Paper Product Making Machinery (554) | US $1,100,000+ | 50% | ≤3h | <15% | $6,000–12,000 | 1 set |

| Zhengzhou Yugong Construction Machinery Co., Ltd. | Henan, CN | Sanitary Napkin Packing Machines (3+ models) | US $990,000+ | 93% | ≤3h | 42% | $1,800–124,000 | 1 set |

| Quanzhou Rainbow Machinery Co., Ltd. | Fujian, CN | Paper Product Making Machinery (516) | - | 100% | ≤5h | - | $7,000–11,600 | 1 set |

| GELGOOG CO., LTD | Hunan, CN | Snack & Fried Food Lines (337) | - | - | ≤2h | - | $15,990–400,000 | 1 set |

Performance Analysis

Dalian Jori stands out with a 100% on-time delivery rate and 68% reorder rate, reflecting strong customer retention and operational reliability. Its competitive pricing and support for color printing, packaging, and size customization make it suitable for buyers seeking scalable snack production lines. GELGOOG offers high-end continuous frying systems with premium automation but lacks verifiable delivery and reorder metrics, posing higher procurement risk for first-time buyers.

Zhengzhou Yugong provides a wide price range, including entry-level feeders at $1,800 and high-speed packing lines above $100,000, catering to both startups and industrial users. Quanzhou Rainbow demonstrates reliability with perfect on-time delivery, though limited response data suggests potential delays in communication. Foshan Meijing, despite extensive product listings, shows low reorder rates (<15%) and moderate delivery performance (50%), indicating possible gaps in after-sales service or machine durability.

FAQs

How to verify automatic namkeen machine supplier reliability?

Validate certifications (CE, ISO) through issuing bodies and request test reports for electrical safety, material composition, and thermal efficiency. Analyze transaction histories for consistent fulfillment patterns and prioritize suppliers with documented export experience to your target market.

What is the typical MOQ and lead time?

Standard MOQ is 1 unit/set across all major suppliers. Lead times vary from 20–45 days depending on customization level. Simple configurations ship within 3 weeks; fully integrated frying and packaging lines may require up to 60 days for final inspection and container loading.

Can suppliers customize machine configuration?

Yes, most suppliers support customization of mold shape (round, square, diamond), feeding system (manual vs. automatic), printing options (logo embossing), and output capacity. Dalian Jori and Zhengzhou Yugong explicitly list options for roll size, label placement, and graphic printing.

Do manufacturers provide installation and training?

Reputable suppliers typically offer remote guidance via video or manuals. On-site commissioning and operator training are available upon request, often included for orders exceeding $20,000. Confirm service terms before contract finalization.

Are spare parts and after-sales support available?

Leading suppliers maintain inventory of critical components (belts, heating elements, molds). Buyers should negotiate warranty periods (typically 12 months) and clarify response timelines for technical issues. Dalian Jori’s high reorder rate suggests effective post-sale engagement and part availability.