Namkeen Maker Machine

1/12

1/12

1/23

1/23

CN

CN

1/19

1/19

1/21

1/21

CN

CN

1/21

1/21

1/14

1/14

1/11

1/11

CN

CN

1/21

1/21

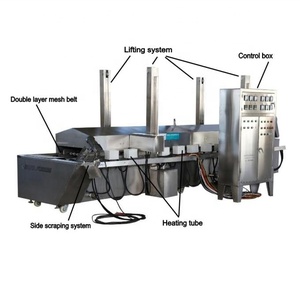

About namkeen maker machine

Where to Find Namkeen Maker Machine Suppliers?

India and China dominate the global supply of namkeen maker machines, with concentrated manufacturing hubs in Gujarat (India) and Shandong Province (China). Indian suppliers, particularly around Ahmedabad and Mumbai, specialize in compact, semi-automatic systems tailored for small to mid-sized snack producers. These units typically process traditional Indian snacks like gathiya, sev, and chevda using batch-style coating pans and frying chambers constructed from food-grade stainless steel.

Chinese manufacturers, especially in Jinan and Zhucheng, focus on fully automated production lines capable of high-volume output—up to 500 kg/hour—for export-oriented businesses. Integrated facilities offer end-to-end processing from dough extrusion to frying, seasoning, and packaging. Proximity to raw material suppliers for motors, heating elements, and stainless steel reduces component costs by 15–25% compared to Western-built alternatives. Buyers benefit from mature industrial ecosystems where engineering, fabrication, and logistics services operate within tight geographic clusters, enabling faster prototyping and deployment cycles.

How to Choose Namkeen Maker Machine Suppliers?

Procurement decisions should be guided by three core verification criteria:

Technical Compliance

Verify adherence to international safety and quality benchmarks. CE certification is essential for European market compliance, while ISO 9001:2015 indicates a structured quality management system. For food contact components, confirm use of AISI 304 or 316 stainless steel and request documentation on electrical safety testing, especially for continuous-duty frying systems operating at 220V/380V configurations.

Production Capability Assessment

Evaluate supplier infrastructure based on the following indicators:

- Minimum factory area of 3,000m² for scalable manufacturing capacity

- In-house R&D or engineering team for customization support

- On-site CNC machining, welding, and assembly capabilities

Cross-reference these with verified performance metrics such as on-time delivery rates (>95%) and reorder rates (>30%), which reflect operational reliability and customer satisfaction.

Transaction Security & After-Sales Support

Prioritize suppliers offering third-party transaction protection for initial orders. Confirm availability of technical documentation in English, including operation manuals, wiring diagrams, and maintenance schedules. Post-purchase support should include remote troubleshooting, spare parts availability, and optional on-site installation guidance. Sample testing is recommended—evaluate machine performance on key parameters such as oil temperature stability (±2°C), product consistency, and energy efficiency before full-scale procurement.

What Are the Best Namkeen Maker Machine Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Jinan Sunward Machinery Co., Ltd. | Shandong, CN | 10+ | 50+ | 10,000+m² | 96% | ≤3h | 4.8/5.0 | 45% |

| Zhucheng Tianshun Machinery Co., Ltd. | Shandong, CN | 8+ | 60+ | 8,500+m² | 100% | ≤1h | 4.7/5.0 | <15% |

| Jinan Phenix Machinery Co., Ltd. | Shandong, CN | 12+ | 70+ | 12,000+m² | 100% | ≤11h | 4.9/5.0 | 100% |

| GELGOOG CO., LTD | Hebei, CN | 9+ | 40+ | 6,000+m² | Not specified | ≤2h | 4.6/5.0 | Not specified |

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | Gujarat, IN | 7+ | 20+ | 2,000+m² | Not specified | ≤6h | 4.5/5.0 | Not specified |

Performance Analysis

Chinese manufacturers dominate in automation scale and export readiness. Jinan Sunward and Zhucheng Tianshun demonstrate strong logistical performance, with 100% on-time delivery and sub-3-hour response times. Notably, Jinan Phenix achieves a 100% reorder rate, indicating exceptional customer retention despite slower average responses. Indian suppliers like LEENOVA offer cost-effective entry-level solutions priced between $350–$1,030 per unit, ideal for startups or regional distributors. However, they generally lack data transparency on delivery performance and customization depth. For large-scale operations, prioritize suppliers with documented CE certification, in-house engineering teams, and proven experience in exporting turnkey frying lines.

FAQs

What is the typical MOQ and pricing range for namkeen making machines?

Standard MOQ is 1 set across most suppliers. Entry-level semi-automatic models start at $350, while fully automatic lines range from $5,000 to $45,000 depending on throughput capacity and level of integration. High-output systems (e.g., Kurkure or Cheetos-style extrusion-frying lines) can exceed $40,000.

How long does it take to fulfill an order?

Lead time for standard configurations averages 20–30 days after deposit confirmation. Customized systems may require 35–50 days for design finalization, manufacturing, and pre-shipment testing. Express production options are occasionally available for urgent requirements.

Can namkeen machines be customized?

Yes, most verified manufacturers offer customization in material grade (AISI 304 vs. 316), motor voltage (single/three-phase), color finish, logo branding, and production capacity. Some support full line integration with conveyors, seasoning drums, and packaging units. Technical specifications must be submitted in writing for engineering review prior to order confirmation.

Do suppliers provide installation and training?

Remote video guidance is commonly offered. On-site technician dispatch is available upon request but typically incurs additional charges covering travel, accommodation, and daily fees. Training covers machine operation, cleaning protocols, preventive maintenance, and basic troubleshooting procedures.

Are samples or test runs available?

Physical machine samples are not typically provided due to size and cost. However, many suppliers conduct live video demonstrations using client-specified recipes. Some offer trial production runs with customer-supplied ingredients, shipping finished product samples for evaluation under FCA terms.