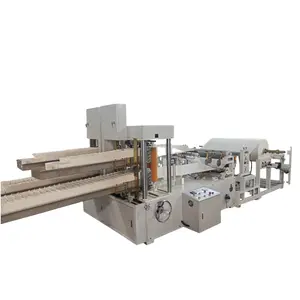

Namkeen Making Machine

About namkeen making machine

Where to Find Namkeen Making Machine Suppliers?

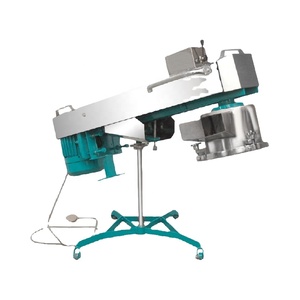

India and China dominate the global supply of namkeen making machines, with distinct regional specializations shaping production efficiency and cost structures. Indian suppliers, particularly in Gujarat and Maharashtra, focus on compact, semi-automatic systems tailored for small to mid-sized snack producers. These units typically operate at 1–5 kW power ranges and support batch processing of traditional Indian snacks like gathiya, sev, and farsan, using food-grade stainless steel (SS304) construction.

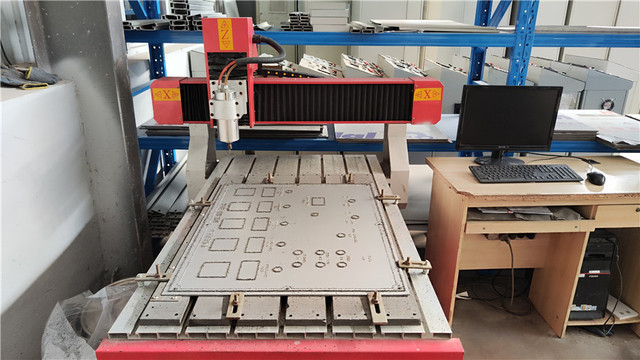

Chinese manufacturers, concentrated in Henan and Shandong provinces, emphasize automation and scalability. Facilities in these regions integrate CNC machining, robotic assembly lines, and modular design principles to produce fully automatic systems capable of 200–500 kg/hour output. Vertical integration—spanning raw material sourcing to final assembly—reduces component lead times by 25–30% compared to decentralized supply models. Buyers benefit from shorter fulfillment cycles (typically 20–35 days for standard orders) and 15–25% lower unit costs due to economies of scale and localized logistics networks.

How to Choose Namkeen Making Machine Suppliers?

Adopt a structured evaluation framework when selecting suppliers:

Technical Compliance

Verify adherence to international safety and quality benchmarks. CE certification is essential for European markets, ensuring compliance with machinery safety directives (2006/42/EC). For food-contact components, confirm use of non-toxic, corrosion-resistant materials (e.g., SS304 or higher) and request documentation such as material test certificates (MTCs) and food-grade compliance reports.

Production Capability Assessment

Evaluate supplier infrastructure based on the following criteria:

- Minimum factory area of 2,000m² indicating capacity for serial production

- In-house engineering teams supporting customization (e.g., extrusion die design, frying temperature control)

- Integrated testing facilities for performance validation under load conditions

Cross-reference on-time delivery rates (target ≥85%) and response time metrics (≤6 hours preferred) to assess operational reliability.

Transaction Security Measures

Utilize secure payment mechanisms such as escrow services to mitigate financial risk. Prioritize suppliers with documented quality management systems (e.g., ISO 9001), though formal certification may be limited among smaller manufacturers. Conduct sample testing to validate machine throughput, energy consumption, and product consistency before placing bulk orders.

What Are the Best Namkeen Making Machine Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order Price | Product Range |

|---|---|---|---|---|---|---|---|---|

| LEENOVA KITCHEN EQUIPMENTS PRIVATE LIMITED | India | Snack & Flour Milling Machinery | Data not available | Data not available | ≤6h | Not disclosed | $310/unit | 4 models |

| Henan Mayjoy Mechanical Equipment Co., Ltd. | Henan, CN | Paper Machinery & Packaging Systems | 92% | 45% | ≤3h | US $260,000+ | $2,600/set | 5 models |

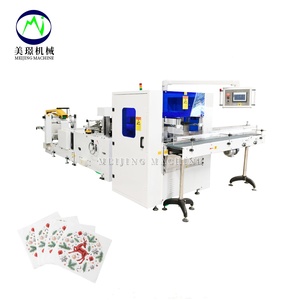

| Foshan Nanhai Meijing Machinery Manufacture Co., Ltd. | Foshan, CN | Paper Product & Tissue Machinery | 50% | <15% | ≤3h | US $1,100,000+ | $6,000/set | 4 models |

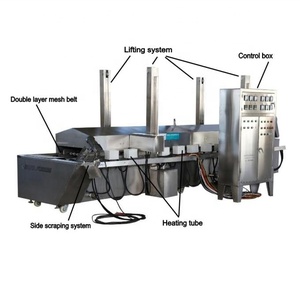

| Zhucheng Tianshun Machinery Co., Ltd. | Shandong, CN | Fried Snack & Commercial Frying Systems | 100% | <15% | ≤1h | US $30,000+ | $2,500/set | 5 models |

| Henan Yugong Machinery Equipment Co., Ltd. | Henan, CN | Paper & Napkin Processing Equipment | 85% | 19% | ≤4h | US $1,100,000+ | $3,350/unit | 5 models |

Performance Analysis

Zhucheng Tiansun stands out with a 100% on-time delivery rate and sub-one-hour average response time, indicating strong internal coordination despite a low reorder rate. Its product line focuses on commercial frying systems integrated into full-line namkeen production setups, priced between $2,500 and $13,500 per set. Henan Mayjoy offers competitive responsiveness (≤3h) and a high reorder rate (45%), suggesting customer satisfaction with after-sales service or machine durability. In contrast, Foshan Meijing reports only 50% on-time delivery despite significant online revenue, signaling potential fulfillment bottlenecks. Indian supplier LEENOVA provides entry-level pricing starting at $310, making it viable for startups or micro-enterprises seeking basic automation.

FAQs

How to verify namkeen making machine supplier reliability?

Cross-check claimed certifications (CE, ISO) through official databases. Request factory audit reports or video walkthroughs to confirm production capabilities. Analyze transaction history, focusing on consistent order volume and verifiable export destinations.

What is the typical lead time for namkeen making machines?

Standard models require 15–30 days for production and packaging. Custom configurations involving specialized dies or control panels may extend lead times to 45 days. Air freight adds 5–7 days; sea freight ranges from 20–40 days depending on destination port.

Do suppliers offer customization options?

Yes, most Chinese suppliers support modifications including voltage (220V/380V), motor power, feeding system type, and discharge height. Some provide OEM branding, logo engraving, and packaging design services. Confirm feasibility through technical drawings and prototype samples before mass production.

What are common minimum order quantities (MOQ)?

MOQ is typically 1 unit or set, allowing low-risk entry for first-time buyers. However, unit prices decrease significantly at volumes exceeding 5 units, especially for automated lines. Negotiate bundled deals for auxiliary equipment (mixers, conveyors, fryers) to optimize total cost of ownership.

Can namkeen machines handle multiple snack varieties?

Multi-die extrusion systems enable versatility across product types (e.g., gathiya, sev, murukku). Confirm die availability and changeover procedures with the supplier. Machines with adjustable speed controls and temperature zones offer greater flexibility in texture and crispness profiling.