Namkeen Making Machine For Factory

1/12

1/12

1/23

1/23

CN

CN

1/19

1/19

1/17

1/17

1/11

1/11

1/15

1/15

CN

CN

1/21

1/21

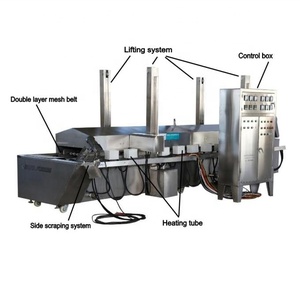

About namkeen making machine for factory

Where to Find Namkeen Making Machine Suppliers for Factory Production?

China remains the dominant hub for industrial-grade namkeen making machine manufacturing, with concentrated supplier clusters in Shandong Province offering specialized expertise in snack food processing equipment. Companies based in Jinan and surrounding regions leverage vertically integrated production ecosystems, combining extrusion, frying, seasoning, and packaging line engineering under one supply chain. This regional specialization enables optimized design-to-delivery cycles for fully automated systems used in large-scale factory operations.

Suppliers in this cluster benefit from proximity to raw material sources—particularly stainless steel and precision mechanical components—reducing input costs by 15–25% compared to non-specialized manufacturers. The presence of established food machinery R&D centers supports innovation in twin-screw extrusion technology, continuous frying systems, and modular automation tailored to regional snack varieties such as Kurkure, Cheetos, Nik Naks, and Bhujia. Buyers gain access to standardized turnkey lines or customizable configurations with lead times averaging 30–60 days, depending on complexity and automation level.

How to Choose Namkeen Making Machine Suppliers for Industrial Use?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify that machines are constructed from food-grade 304 stainless steel and comply with international safety standards such as CE or ISO 9001. For export markets, confirm electrical compatibility (voltage: 380V/50Hz standard) and integration readiness with existing plant infrastructure. Demand full technical documentation including process flow diagrams, power consumption metrics, and capacity benchmarks (typically 100–500 kg/hour for mid-range lines).

Production Capacity & Customization

Assess supplier capabilities through key indicators:

- Minimum factory area exceeding 3,000m² to support full-line assembly

- In-house engineering teams capable of system customization (e.g., flavor coating integration, shape die design)

- Proven experience in delivering complete processing lines—not just standalone units

Cross-reference product listings with on-time delivery performance and response efficiency to gauge reliability.

Procurement Safeguards

Utilize secure payment frameworks such as trade assurance or escrow services until final inspection is completed. Request sample production runs or video demonstrations of machine operation prior to order confirmation. Prioritize suppliers offering post-installation support, including commissioning guidance and operator training, especially for complex extrusion-frying-seasoning sequences.

What Are the Leading Namkeen Making Machine Suppliers for Factories?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Jinan Shengrun Machinery Co., Ltd. | Shandong, CN | Food processing lines, Snack Machines, Pet Food & Feed Processing | US $80,000+ | 100% | ≤4h | Not disclosed | $5,999–$41,000 | Limited |

| GELGOOG CO., LTD | Shandong, CN | Food processing lines, Snack & Biscuit Machines, Vegetable Equipment | Not disclosed | Not disclosed | ≤2h | Not disclosed | $15,990–$17,990 | Standard models |

| Jinan Sunward Machinery Co., Ltd. | Shandong, CN | Snack Machines, Extrusion Lines, Customizable Systems | US $880,000+ | 96% | ≤3h | 45% | $5,000–$40,000 | Color, size, logo, capacity, packaging |

| YANN TECHNOLOGY LLC | Hebei, CN | Grain, Meat & Multi-Function Packaging Machines | Not disclosed | Not disclosed | ≤1h | Not disclosed | $280–$1,700 | Not applicable |

| Jinan Phenix Machinery Co., Ltd. | Shandong, CN | Snack Machines, Food & Feed Processing Lines | US $40,000+ | 100% | ≤11h | 100% | $8,000–$45,000 | Model-specific |

Performance Analysis

Jinan Sunward Machinery stands out with the highest reported online revenue (US $880,000+) and extensive customization options, indicating strong market acceptance and client-centric adaptability. Jinan Phenix Machinery demonstrates exceptional customer retention with a 100% reorder rate, suggesting consistent quality and service fulfillment despite slower average response times. GELGOOG CO., LTD excels in responsiveness (≤2h), making it suitable for time-sensitive procurement cycles. Notably, multiple suppliers offer machines in the $5,000–$8,000 range, targeting entry-level automation, while premium configurations exceed $40,000 for fully integrated lines with high-capacity extrusion and continuous frying modules.

FAQs

What is the typical MOQ and lead time for factory-grade namkeen making machines?

Minimum Order Quantity is typically 1 set, allowing pilot testing and scalability assessment. Lead times range from 30 to 60 days after deposit confirmation, depending on automation level and customization requirements. Express production may be available for standard models at an additional cost.

Do suppliers offer customization for specific snack types?

Yes, leading suppliers provide die customization for product shapes (sticks, curls, rings), adjustable moisture control, and integrated seasoning drums. Full line engineering can include feeding, extrusion, cutting, frying, de-oiling, flavoring, and packaging modules tailored to local taste profiles.

Are CE or ISO certifications standard among these suppliers?

Certification availability varies. While some suppliers claim compliance, buyers must request verifiable documentation. Third-party audits or factory video inspections are recommended to confirm adherence to ISO 9001 or CE safety directives before procurement.

Can these machines handle different raw materials?

Most industrial namkeen machines use twin-screw extrusion systems compatible with corn, maize, rice, and wheat-based formulations. Adjustments to screw speed, temperature zones, and die pressure allow flexibility across base ingredients, supporting diverse product development.

What logistical support do suppliers provide for international shipping?

Established exporters offer FOB, CIF, or DAP shipping terms with containerized packing suitable for sea freight. Buyers should confirm inclusion of disassembly guides, spare parts kits, and voltage adaptation for destination-grid compatibility. Pre-shipment inspection services are often available upon request.