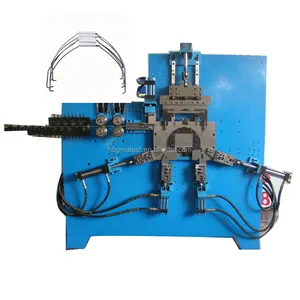

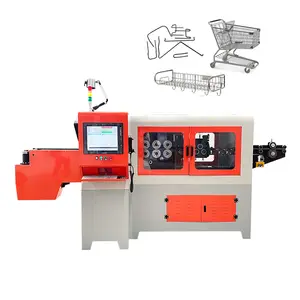

Automatic Wire Binding Machine

1/45

1/45

1/14

1/14

About automatic wire binding machine

Where to Find Automatic Wire Binding Machine Suppliers?

China remains the global epicenter for automatic wire binding machine manufacturing, with key production hubs concentrated in Guangdong, Henan, and Zhejiang provinces. Shenzhen (Guangdong) hosts advanced electronics-integrated machinery producers, leveraging proximity to component suppliers and export ports for rapid fulfillment. Zhengzhou (Henan) and Hangzhou (Zhejiang) serve as centers for precision engineering, specializing in high-speed, industrial-grade binding systems used in commercial printing and bookbinding operations.

These regional clusters benefit from vertically integrated supply chains—spanning servo motors, CNC-formed dies, and automated feeding mechanisms—enabling competitive pricing and scalable output. Suppliers in these zones typically operate under ISO-aligned quality frameworks and offer lead times averaging 25–40 days for standard configurations. Buyers gain access to flexible production runs, with some manufacturers supporting MOQs as low as one set, particularly for semi-automated or compact models designed for mid-volume print shops.

How to Choose Automatic Wire Binding Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Verify adherence to international safety and performance standards such as CE and ISO 9001. For export-bound equipment, confirm electromagnetic compatibility (EMC) and RoHS compliance where applicable. Assess design sophistication through product specifications: advanced models integrate programmable logic controllers (PLCs), touch-screen interfaces, and auto-calibration features for coil diameter and sheet count.

Production Infrastructure Assessment

Evaluate supplier capabilities based on tangible indicators:

- Facility size exceeding 3,000m² indicating capacity for batch production

- In-house R&D teams focused on electromechanical integration

- CNC machining, laser cutting, and robotic welding capabilities

Cross-reference online revenue metrics and on-time delivery rates (target ≥92%) to assess operational stability and order prioritization practices.

Customization & Quality Assurance Protocols

Confirm availability of customization options including voltage (110V/220V), coil size range (3:1 to 5:1 pitch), and integration with upstream punching units. Require documented QC procedures covering pre-shipment testing of cycle durability (≥10,000 cycles benchmark) and alignment accuracy. Prioritize suppliers offering factory inspection reports or video audits upon request.

What Are the Best Automatic Wire Binding Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Key Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Hongyuan Stationery Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $20,000+ | 100% | ≤2h | <15% | High-end automatic punching & binding systems | Color, material, size, logo, packaging, label, graphic |

| Zhengzhou Miles Tech Company Ltd. | Henan, CN | Multispecialty Supplier | US $1,000,000+ | 92% | ≤3h | 15% | Single-head, elliptic, glue-binding hybrids | Conveyor blades, thickness, length, power, slitting, diameter, width |

| Suzhou Hope Trend Import & Export Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | US $110,000+ | 100% | ≤2h | 20% | 3D CNC wire benders, stainless steel formers | Color, material, size, logo, label |

| Hangzhou Qike Technology Co., Ltd. | Zhejiang, CN | Not Specified | US $50,000+ | 92% | ≤1h | 16% | Double-head, electric single-head, Hohner-style | Limited public data |

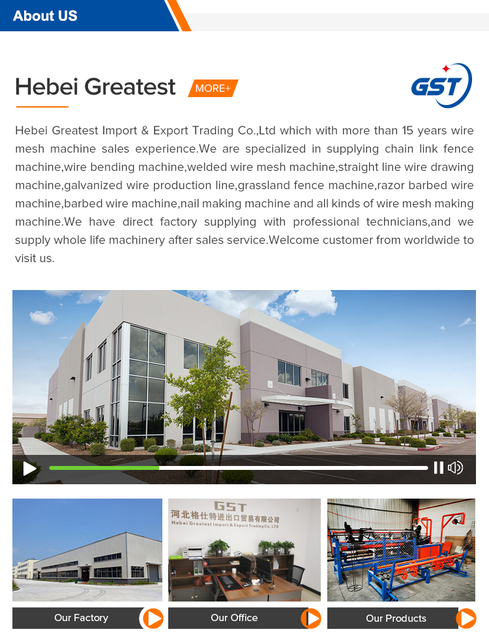

| Hebei Greatest Import Export Trading Co., Ltd. | Hebei, CN | Not Specified | US $150,000+ | 100% | ≤2h | <15% | Stainless steel, barbed wire, mechanical benders | Material, size, diameter, logo, color |

Performance Analysis

Shenzhen Hongyuan and Suzhou Hope Trend demonstrate flawless on-time delivery (100%), making them strong candidates for time-sensitive procurement. Zhengzhou Miles stands out with the highest reported online revenue (US $1M+), suggesting extensive market reach and diversified product validation. Hangzhou Qike excels in responsiveness (≤1h average), critical for iterative technical discussions. While Hebei Greatest offers competitive entry-level pricing (from $2,000/set), its focus appears broader than dedicated office binding solutions, potentially affecting specialization depth. Suppliers with comprehensive customization portfolios are better suited for integrators requiring OEM branding or system interoperability.

FAQs

How to verify automatic wire binding machine supplier reliability?

Cross-check certifications (ISO, CE) through official registries and request test reports for electrical safety and mechanical endurance. Analyze transaction history via verified revenue tiers and delivery performance. Conduct virtual factory tours to assess assembly line organization and inventory management practices.

What is the typical lead time for custom automatic wire binding machines?

Standard orders ship within 25–35 days. Customized units with modified feed mechanisms or control panels require 40–55 days, depending on complexity. Add 7–14 days for air freight or 25–40 days for sea shipping based on destination.

Do suppliers support low-volume or sample orders?

Yes, most suppliers accept MOQs of 1 set, enabling functional testing. Sample units are typically sold at full price unless offset by subsequent bulk orders. Some vendors offer partial refunds if samples convert into larger contracts.

Are there common customization options available?

Standard customization includes voltage adaptation, coil diameter range, enclosure color, and branding (logo, labels). Advanced modifications involve PLC interface upgrades, dual-station operation, or integration with inline punch modules. Confirm feasibility through technical drawings before commitment.

What payment and logistics terms should be expected?

Common payment terms include T/T (30% deposit, 70% before shipment) or platform-based escrow. FOB terms are standard; CIF can be arranged for full-container loads. Ensure packaging meets international standards for vibration and moisture resistance during transit.