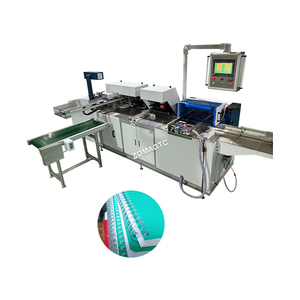

Spiral Binding Machine Automatic Producer

1/3

1/3

1/17

1/17

0

0

1/1

1/1

1/3

1/3

1/3

1/3

1/45

1/45

1/3

1/3

1/15

1/15

CN

CN

1/18

1/18

1/15

1/15

1/3

1/3

1/13

1/13

1/16

1/16

1/9

1/9

1/3

1/3

1/19

1/19

1/3

1/3

About spiral binding machine automatic producer

Where to Find Spiral Binding Machine Automatic Producers?

China remains the global epicenter for spiral binding machine manufacturing, with specialized industrial clusters in Guangdong and Zhejiang provinces driving innovation and scale. Dongguan and Hangzhou serve as primary hubs, hosting vertically integrated facilities capable of full-cycle production—from CNC machining and electrical assembly to final testing. These regions benefit from mature supply chains for precision components such as servo motors, punching dies, and coil-forming mechanisms, reducing lead times by 20–30% compared to non-specialized manufacturers.

Suppliers in these clusters typically operate dedicated automation lines for spiral wire forming, hole punching, and binding assembly, supporting both plastic and metal coil applications. The concentration of technical talent and component vendors within 50km enables rapid prototyping and just-in-time production. Buyers can expect standard lead times of 30–45 days for custom configurations, with monthly output capacity ranging from 50 to 300 units per facility, depending on automation level and product complexity.

How to Choose Spiral Binding Machine Automatic Producers?

Effective supplier selection requires systematic evaluation across three critical dimensions:

Technical and Production Capability

Prioritize suppliers with documented in-house engineering teams and automated assembly lines. Key indicators include CNC machining centers, robotic wire-forming stations, and integrated PLC control systems. Confirm minimum factory areas of 3,000m² for high-volume reliability. Suppliers advertising "own production line" should provide verifiable evidence through facility videos or audit reports.

Quality Assurance and Compliance

While ISO 9001 certification is not universally listed, consistent on-time delivery rates above 95% and response times under 3 hours indicate robust internal quality management. For export markets, CE marking is essential for compliance with EU machinery directives. Request test reports on cycle durability (e.g., ≥500,000 binding operations) and electrical safety standards (IEC 60204-1).

Transaction and Sourcing Metrics

Analyze reorder rates and online transaction volume as proxies for customer satisfaction. Suppliers with reorder rates exceeding 25%—such as Hangzhou Befitter Machinery—demonstrate strong post-sale performance. Minimum Order Quantities (MOQ) vary: most set MOQ at 1 unit, facilitating low-risk sampling. Unit pricing spans $390 to $48,800, reflecting differences in automation level, binding width (A4 to A3+), and material compatibility (plastic, metal, double-loop).

What Are the Leading Spiral Binding Machine Automatic Producers?

| Company Name | Location | Main Products | On-Time Delivery | Response Time | Online Revenue | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Dongguan City Jiuxin Intelligent Machinery Co., Ltd. | Guangdong, CN | Paper Product Making Machinery, Packaging Machines | 100% | ≤3h | Not disclosed | Not disclosed | $24,000–48,800 | 1 piece/set |

| Hangzhou Befitter Machinery & Electronic Co., Ltd. | Zhejiang, CN | Customizable Binding & Electronic Systems | 93% | ≤5h | US $270,000+ | 25% | $390–60,857 | 1 piece |

| Hangzhou Fuyang Sigo Office Supplies Co., Ltd. | Zhejiang, CN | Binding Machines, Laminators, Paper Trimmers | 96% | ≤2h | US $1,500,000+ | <15% | $95–6,500 | 1–2 units |

| Dongguan Hengbo Binding Machinery Co., Ltd. | Guangdong, CN | Binding Machines, Laminators | 100% | ≤2h | US $4,000+ | <15% | $5,000–25,000 | 1 set/km |

| Dongguan Ganghua Bookbinding Equipment Co., Ltd. | Guangdong, CN | Binding Machines, Hole Punches, Laminators | 100% | ≤2h | US $40,000+ | <15% | $4,500–8,000 | 1 set |

Performance Analysis

Dongguan-based producers like Jiuxin and Hengbo demonstrate exceptional reliability with 100% on-time delivery, indicating disciplined production planning. However, their higher price points ($24,000+) reflect advanced automation and industrial-grade construction. In contrast, Hangzhou Sigo offers competitive entry-level models starting at $95, suitable for small-scale operations, though lower reorder rates suggest room for improvement in long-term customer retention. Hangzhou Befitter stands out with a 25% reorder rate and customization capabilities in materials, color, and branding, making it ideal for buyers seeking tailored solutions. Response times across Guangdong suppliers are consistently fast (≤2h), enhancing communication efficiency during technical negotiations.

FAQs

How to verify spiral binding machine producer credibility?

Cross-check claimed production capabilities with video audits or third-party inspection services. Request references from existing clients, particularly those in similar production environments. Validate machine specifications against industry benchmarks for binding speed (e.g., 300–600 books/hour) and wire diameter compatibility (1.5–6mm).

What is the typical sampling timeline?

Standard sample production takes 15–25 days, depending on customization level. Fully automatic models with integrated feeding systems may require up to 40 days. Air freight shipping adds 7–10 days internationally. Some suppliers offer sample discounts redeemable against bulk orders.

Can producers handle global shipping and customs compliance?

Yes, experienced exporters manage FOB and CIF terms, including export documentation and container loading. Confirm CE or other regional certifications are provided for customs clearance. Sea freight is recommended for multi-unit orders to minimize logistics costs.

Do suppliers support OEM/ODM customization?

Many producers, including Hangzhou Befitter and Dongguan Ganghua, offer OEM services for branding, interface language, and mechanical adjustments. Customization scope includes voltage (110V/220V), control panels (PLC/HMI), and integration with upstream/downstream equipment.

What are standard payment and quality assurance terms?

Common payment structures include 30% T/T deposit with balance before shipment. Escrow services are advised for first-time transactions. Pre-shipment inspections—either buyer-conducted or via third parties—are critical to verify machine functionality, noise levels, and safety guards.