Spiral Binding Machine Distributor

1/34

1/34

1/23

1/23

1/45

1/45

1/3

1/3

1/15

1/15

1/3

1/3

0

0

1/10

1/10

1/15

1/15

1/19

1/19

1/29

1/29

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/24

1/24

CN

CN

1/18

1/18

1/3

1/3

About spiral binding machine distributor

Where to Find Spiral Binding Machine Suppliers?

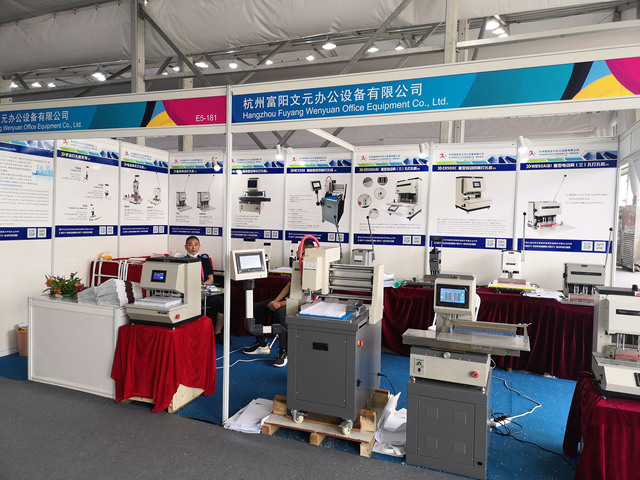

China remains the central hub for spiral binding machine manufacturing, with key production clusters in Zhejiang, Guangdong, and Henan provinces. These regions host vertically integrated supply chains that support both compact desktop models and industrial-scale binding systems. Dongyang in Zhejiang is recognized for its concentration of office equipment manufacturers, enabling rapid prototyping and low-to-mid volume production. Shenzhen and Hangzhou facilities specialize in electric and semi-automatic machinery, leveraging proximity to electronics component suppliers to reduce assembly lead times by 15–20% compared to offshore alternatives.

The industrial ecosystems in these zones combine precision engineering workshops, tooling centers, and packaging lines within close geographic proximity, allowing suppliers to fulfill orders efficiently across varying MOQs. Buyers benefit from localized access to steel, plastic coil extrusion units, and CNC machining services, which contribute to cost stability and faster turnaround. Standard delivery windows range from 15–30 days for stock models, while customized configurations typically require 25–40 days depending on technical complexity.

How to Choose Spiral Binding Machine Suppliers?

Effective supplier selection requires a structured evaluation across three core areas:

Technical Capability & Compliance

Verify that suppliers adhere to international safety and performance benchmarks. CE marking is essential for European market compliance, particularly for electric models operating above 50V. While ISO 9001 certification is not universally held among smaller manufacturers, its presence indicates formalized quality management systems. Request documentation on motor durability testing, gear wear resistance, and die-cutting precision—especially for high-volume binding applications.

Production Infrastructure Assessment

Evaluate operational scale through measurable indicators:

- Facility size exceeding 1,000m² for consistent output capacity

- In-house tooling and mold-making capabilities for customization agility

- Integration of CNC punching and hydraulic pressing units for hole-punch accuracy

Cross-reference online revenue metrics and on-time delivery rates (target ≥98%) as proxies for operational reliability and order prioritization.

Procurement Risk Mitigation

Utilize transaction protection mechanisms such as escrow payment terms for initial orders. Prioritize suppliers offering sample validation with return policies or credit against bulk purchases. Confirm packaging standards (e.g., wooden crates for heavy-duty machines) and export experience, particularly for automated models requiring voltage adaptation (110V/220V).

What Are the Best Spiral Binding Machine Suppliers?

| Company Name | Location | Verified As | Product Range | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Dongyang Zequan Office Supplies Co., Ltd. | Zhejiang, CN | Custom Manufacturer | 5 | 99% | ≤2h | US $160,000+ | <15% | Color, material, size, logo, packaging, label, graphic |

| Rayson Electrical Mfg., Ltd. | Guangdong, CN | Custom Manufacturer | 3 | 98% | ≤3h | US $130,000+ | <15% | Color, material, size, logo, packaging, label, graphic |

| Shenzhen Hongyuan Stationery Co., Ltd. | Guangdong, CN | Custom Manufacturer | 5 | 90% | ≤2h | US $20,000+ | <15% | Color, material, size, logo, packaging, label, graphic |

| Hangzhou Gino Tech Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | 4 | 99% | ≤2h | US $650,000+ | <15% | Color, material, size, logo, packaging, label, graphic |

| Henan Yingsheng Supply Chain Management Co., Ltd. | Henan, CN | Not Specified | 4 | 100% | ≤2h | US $40,000+ | <15% | Paper Processing Machinery, Post-Press Equipment |

Performance Analysis

Dongyang Zequan and Hangzhou Gino Tech demonstrate strong responsiveness and delivery consistency, with on-time fulfillment at 99% and sub-2-hour response times. Hangzhou Gino stands out with significantly higher online revenue (US $650,000+), suggesting robust export activity and diversified product offerings, including heavy-duty electric models priced above $300. Henan Yingsheng reports perfect on-time delivery (100%), indicating reliable logistics execution despite lower sales volume. Suppliers based in Zhejiang and Guangdong offer broader customization depth, particularly in branding and mechanical configuration. For buyers seeking industrial-grade automation, prioritize companies listing semi-automatic or all-in-one systems with documented production capacity.

FAQs

How to verify spiral binding machine supplier reliability?

Validate certifications (CE, ISO) through independent registries and request test reports for electrical components and mechanical stress tolerance. Analyze transaction history, focusing on dispute resolution records and customer feedback related to machine calibration and after-sales service.

What is the typical minimum order quantity (MOQ)?

MOQ varies by model and supplier: manual desktop units often have MOQs of 1–4 pieces, while automated or industrial systems may require 10+ units. Some suppliers adjust pricing tiers at specific volumes (e.g., 10, 50, or 100 units).

Can spiral binding machines be customized?

Yes, most suppliers support customization in housing color, punch pattern (21-hole, 34-hole), voltage specification, branding (logo imprinting), and packaging design. Confirm tooling costs and development timelines—typically 7–14 days for design approval and prototype testing.

What are common price ranges for spiral binding machines?

Manual models range from $18–$35 per unit. Electric or semi-automatic systems cost $60–$400, while fully automated industrial machines can exceed $60,000. Pricing correlates with punching speed, coil diameter compatibility, and build material (aluminum vs. plastic housings).

Do suppliers offer samples?

Sample availability depends on machine type. Desktop models are frequently offered as paid samples ($20–$50, credited toward bulk orders). For large electric or industrial machines, suppliers may require partial payment or deposit before sample production, with lead times of 10–20 days.